- Joined

- May 6, 2014

- Messages

- 17,487

- Reaction score

- 16,593

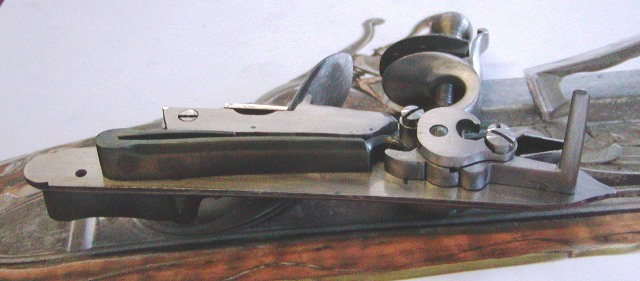

OK, going back to this pic and BEFORE reducing the body of the Fly, here is something that needs corrected first.

In this pic the lower or left vertical edge of the cut out for the fly needs to be cleaned up straight and perpendicular to the bottom of the cut out. It should probably be further filed at an angle more to the left so the front bottom of that edge is even with the bottom of the curved surface under the half cock notch. This will give more room for the Fly to move lower/to the left and will give more room for the Fly to be out of the way for the Sear Nose to fully enter the Half Cock notch.

One has to be careful of not messing up the flat portion of the bottom of cut out for the Fly when doing this. As that can cause the fly to not slide smoothly.

It would be best to have a small "Safe Edge" square or rectangular file to do this with so the "Safe Edge" or edge that has the teeth removed is placed on the flat bottom of the relief cut while filing, so the file doesn't cut into the bottom shelf.

Of course the edges need "de-burring" or slightly chamfer relieved once the new forward angled edge is achieved.

Gus

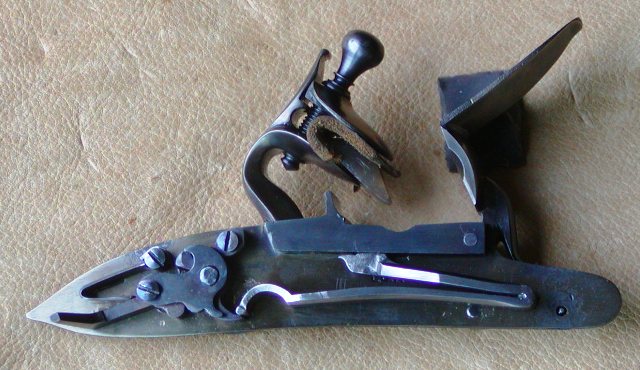

In this pic the lower or left vertical edge of the cut out for the fly needs to be cleaned up straight and perpendicular to the bottom of the cut out. It should probably be further filed at an angle more to the left so the front bottom of that edge is even with the bottom of the curved surface under the half cock notch. This will give more room for the Fly to move lower/to the left and will give more room for the Fly to be out of the way for the Sear Nose to fully enter the Half Cock notch.

One has to be careful of not messing up the flat portion of the bottom of cut out for the Fly when doing this. As that can cause the fly to not slide smoothly.

It would be best to have a small "Safe Edge" square or rectangular file to do this with so the "Safe Edge" or edge that has the teeth removed is placed on the flat bottom of the relief cut while filing, so the file doesn't cut into the bottom shelf.

Of course the edges need "de-burring" or slightly chamfer relieved once the new forward angled edge is achieved.

Gus

Last edited: