Josh Smith

45 Cal.

- Joined

- Sep 24, 2010

- Messages

- 907

- Reaction score

- 0

Hello,

I'm barely keeping my groups in the 9 ring at 50 yards. Granted, I can't see worth manure, but I'm not liking the looks of a few patches that came from my rifle.

Patch material is .008" pillow ticking (off one of my old pillows), compressible to .0075". Load is 70gn Pyrodex FFg.

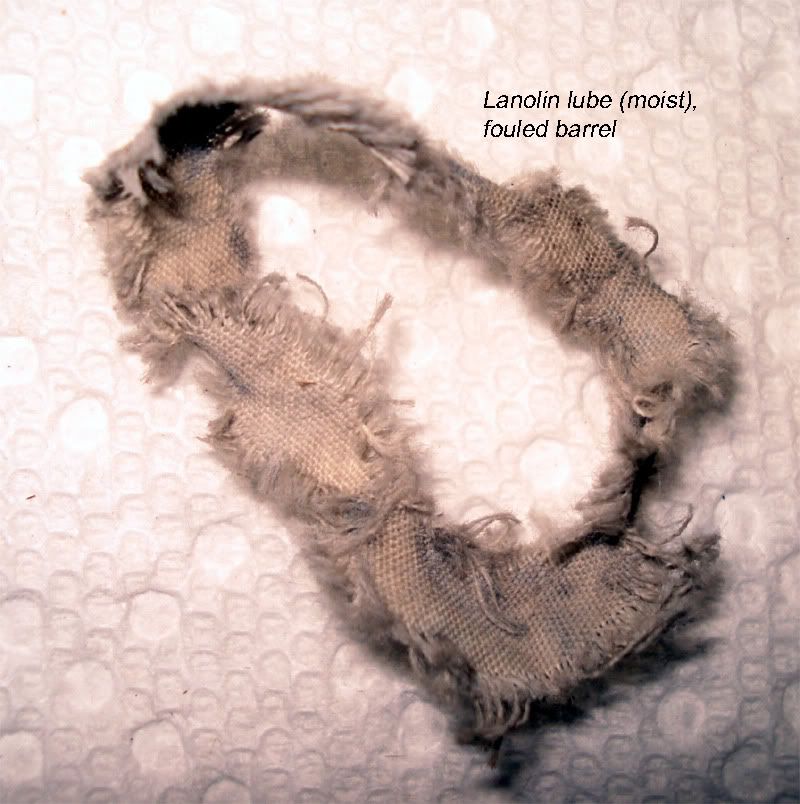

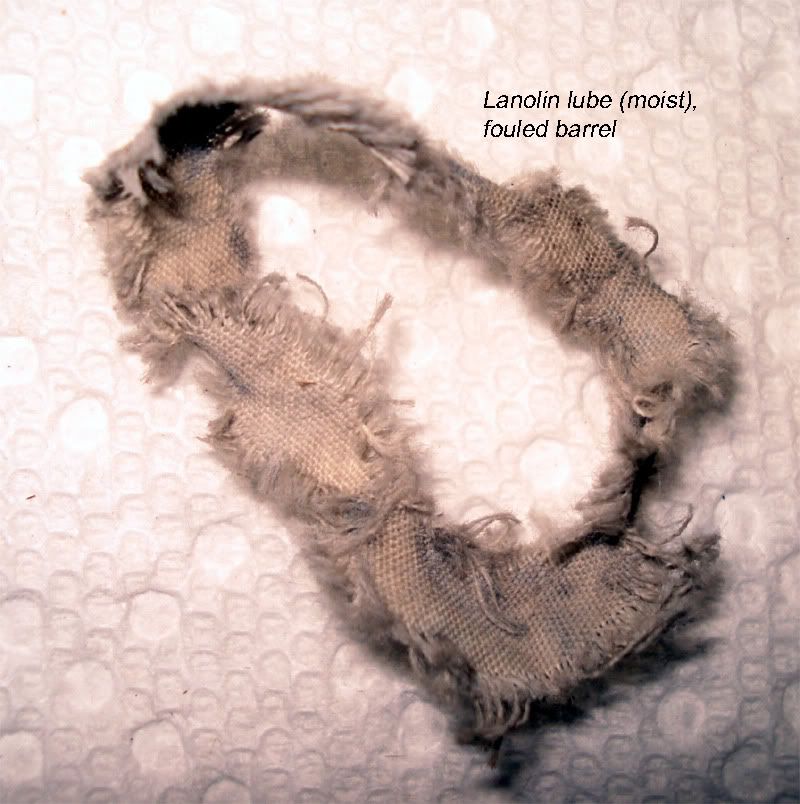

Lube moistened patch (just enough to feel it)...

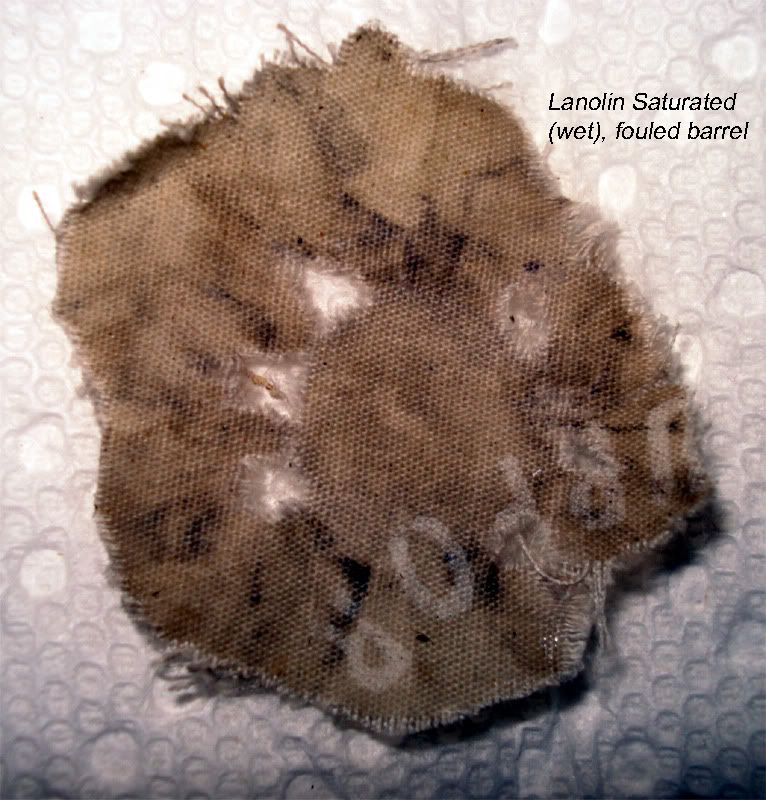

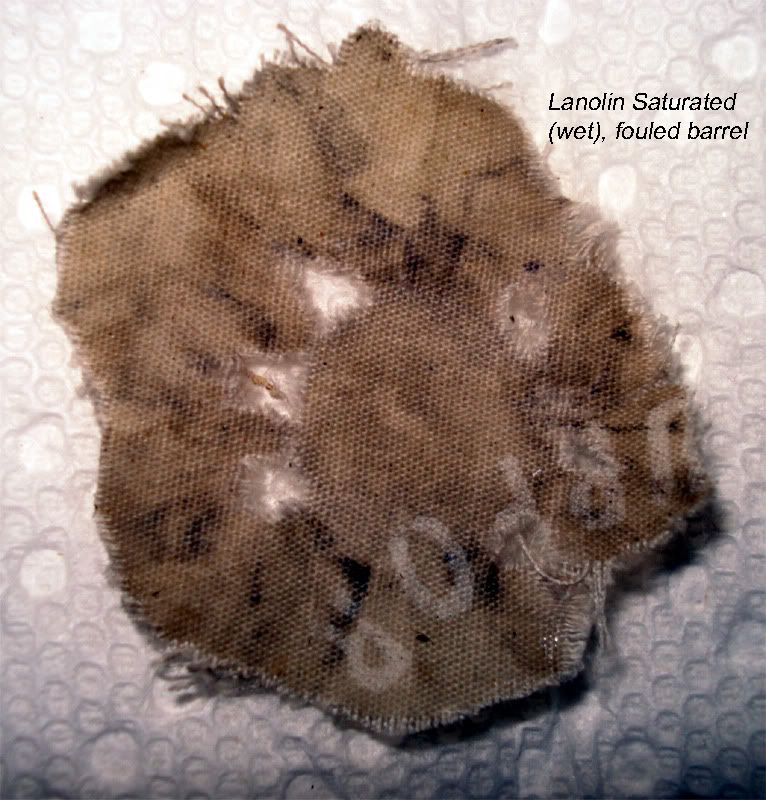

Lube saturated patch (can see it standing and wets things it touches...

Same as the second pic...

I was using old T-shirt material, but was told that it was too loosely woven. However, I was getting decent accuracy and it was holding together like the number two and three patches with just spit lubed.

I think this stuff is just old and thin, and blowing apart. I know I find lots of lil' pieces in front of the rifle if they're not saturated.

The balls are supposed to cast at .490", but they mic at .492".

Thoughts?

Thanks,

Josh

I'm barely keeping my groups in the 9 ring at 50 yards. Granted, I can't see worth manure, but I'm not liking the looks of a few patches that came from my rifle.

Patch material is .008" pillow ticking (off one of my old pillows), compressible to .0075". Load is 70gn Pyrodex FFg.

Lube moistened patch (just enough to feel it)...

Lube saturated patch (can see it standing and wets things it touches...

Same as the second pic...

I was using old T-shirt material, but was told that it was too loosely woven. However, I was getting decent accuracy and it was holding together like the number two and three patches with just spit lubed.

I think this stuff is just old and thin, and blowing apart. I know I find lots of lil' pieces in front of the rifle if they're not saturated.

The balls are supposed to cast at .490", but they mic at .492".

Thoughts?

Thanks,

Josh