Guest

.... shooting,what brand/type/cal etc. would you buy and why? thanks in advance

I'd contact a custom gunmaker with a good reputation for making accurate rifles.....of course I may be a little biased. :hmm:

In general, if you go for something cheap, you'll get exactly what you pay for.

Greeting Pepperbelly,

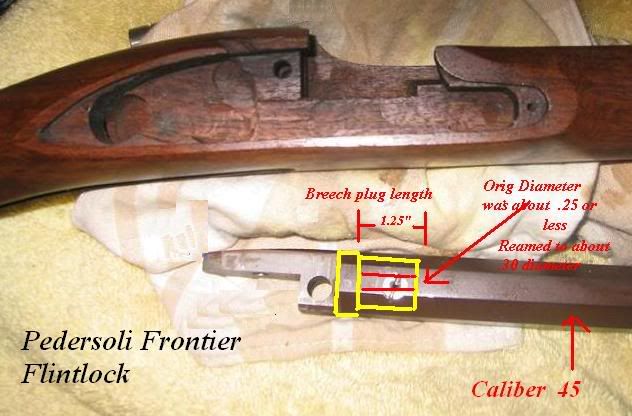

I have a friend who has a Pedersoli Frontier flintlock in 45 caliber. It is a very nice looking rifle and appears to be well built.

Last week he brought it over, and out to the range we went.

With a 50 grain charge of Goex 3FFF blackpowder. .445 Speer ball, and .018 pillow ticking lubed with Ox-Yoke Wonderlube, we begin shooting at 25 yards.

The rifle shot about 10 inches low at 25 yards, so out with the file and lowering the front sight.

After shooting and filing for 20-25 rounds we were still shooting about 1-1/2 inches low. About 1/2 of the front sight height was removed, and I did not want to remove any more of the sight. It was decided to replace the rear sight with a higher sight. The factory sights are not adjustable, and elevation adjustments can be regulated only by filing.

At that point, we decided to work on developing some accurate loads. It was then we begin to experience misfires and no fires. The touch hole was picked repeatedly before and after loading each shot.

During the picking after each misfire/no fire there was no indication of powder behind the touch hole liner, so it was decided to remove the touch hole liner and have a look.

Surprise! Surprise! Not only was there no powder, but the reason was discovered why.

To begin with, ALL PEDERSOLI FRONTIER RIFLE OWNERS, FLINT OR CAP PAY ATTENTION.

The Fontier rifle breech is very long (about 1-3/8 inches long and uses a powder chamber drilled into the front half of the breech. In addition, the BARREL AND BREECH is threaded so that the touch hole liner and/or percussion drum must be removed are screwed through both barrel and breech. This design is also used in CVA rifles.

This is a very secure and safe breeching method, but in this instance, another problem and the most likely cause for the mifires/no fires was observed. The diameter of the powder chamber was very small. After 20-25 shots, burnt blackpowder residue had built up and choked the powder chamber closed.

Well, right or wrong. I do not want to be flushing or scraping the breech of a rifle every 20-25 shots. particularly during a competetive event. Wondering if your rifle is going to fire with every shot is not good for your concentration and focus on getting a good shot off.

So, it was clean up and back to the house and shop.

AFTER FIRST REMOVING THE VENT HOLE LINER, the breech was removed and yes the powder chamber was blocked with burnt black powder residue. The diameter of the powder chamber measured between 15/64 and 1/4 inch. Too small in my opinion.

The breech was screwed into a threaded collar and chucked up in my lathe and step-drilled out to 5/16 inch diameter. It MIGHT BE ok to drill the breech out to 11/32 inch since the breech plug threads are completely enclosed by the barrel threads. However, I was very comfortable with the 5/16 inch size and have successfully used this size with other breechs I have custom machined from scratch. Keep in mind, the barrel is only 13/16 inch across the flats.

After finish drilling, the powder chamber was given a high polish.

By the way, I neglected to mention that the breech was easily removed once the touch hole liner was FIRST removed.

The rifle was re-assembled and is awaiting a new rear sight before shooting again.

I have confidence that drilling the powder chamber to a larger diameter will solve the misfire problem and is also safe. I do not fault Pedersoli for the breech design. I feel they wanted to increase the safety factor by increasing the amount of threads used to hold the vent hole liner and particularly the drum for percussion use. I also suspect this rifle might be easily be converted to use as either flintlock or caplock.

If there are other Pedersoli Frontier rifle owners who are experiencing this or a similar problem, my approach to solving the problem might be considered.

The drilling is not irreversable. A sleeve or bushing can be turned, drilled, and fitted in place. I did this for a friend who had a too large powder chamber. It was larger in diameter than the bore. Even used a piece of stainless steel for the bushing.

Best regards and good shooting,

John L. Hinnant

Enter your email address to join: