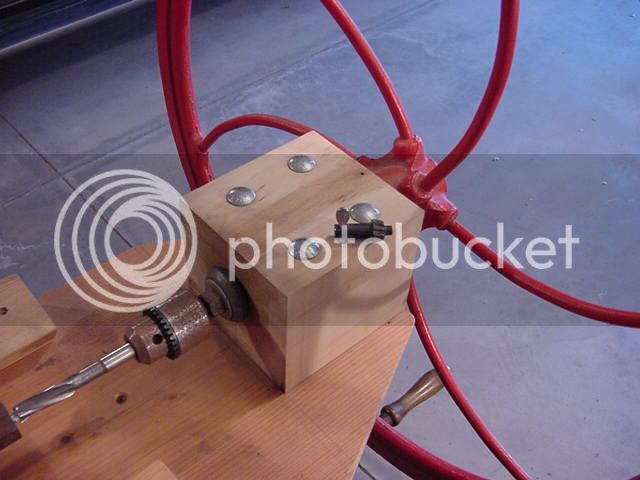

Bookie

40 Cal.

If any of you are interested, I will be conducting rifle boring and reaming (all traditional) hands on classes over the next few days, here at Toad Hall. We are also turning blank rifling guides or "worms". The hand rifling seminar is just completed today. No charge. You can find my website in my personal data. Cheers, Bookie