Ghost: I hear what your saying but I have seen more damage done by the old Arkansas stone (and similar hand held devices) than anything a LIGHT use of a buffing wheel could ever do.

As you say, the angles on these surfaces are critical and there is no way a hand held stone can duplicate or maintain these angles unless it is done by someone with years of experence.

The nice thing about buffing these parts is the angle and depth of the features is not really changed.

Please note, I made a point of saying that the edges of the sear/tumbler must not be removed or rounded off. (If I didn't, I meant to).

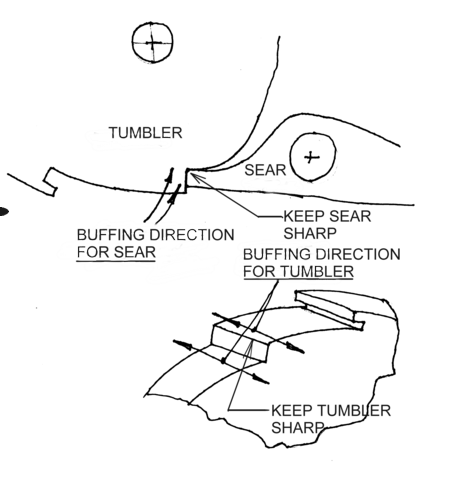

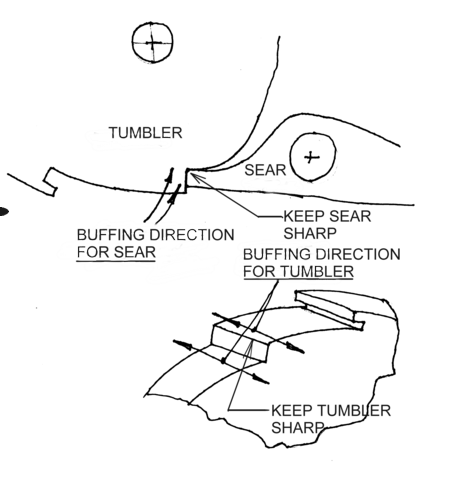

I did fail to mention that the technique used on the sear is to buff from the top of the sear, down towards the sharp edge which engages the flat on the tumbler. Using this method will leave the sharp edge sharp.

The tumbler on the other hand is buffed across the width of the part, Parallel with the sharp edge of the notch, never from the top down towards the sharp edge. See the picture below for a better understanding.

Using this method, the maximum material removed is much less than .002.

I have used this method on all of my guns and NEVER had a problem with unwanted sear releases.

As for who is right or who is wrong about this subject, I will wait and see what others have to say.

As you say, the angles on these surfaces are critical and there is no way a hand held stone can duplicate or maintain these angles unless it is done by someone with years of experence.

The nice thing about buffing these parts is the angle and depth of the features is not really changed.

Please note, I made a point of saying that the edges of the sear/tumbler must not be removed or rounded off. (If I didn't, I meant to).

I did fail to mention that the technique used on the sear is to buff from the top of the sear, down towards the sharp edge which engages the flat on the tumbler. Using this method will leave the sharp edge sharp.

The tumbler on the other hand is buffed across the width of the part, Parallel with the sharp edge of the notch, never from the top down towards the sharp edge. See the picture below for a better understanding.

Using this method, the maximum material removed is much less than .002.

I have used this method on all of my guns and NEVER had a problem with unwanted sear releases.

As for who is right or who is wrong about this subject, I will wait and see what others have to say.