Josh Wrightsman

32 Cal.

- Joined

- Jan 14, 2015

- Messages

- 16

- Reaction score

- 0

Hey guys. I'm fairly new here on the forums and to rifle building.

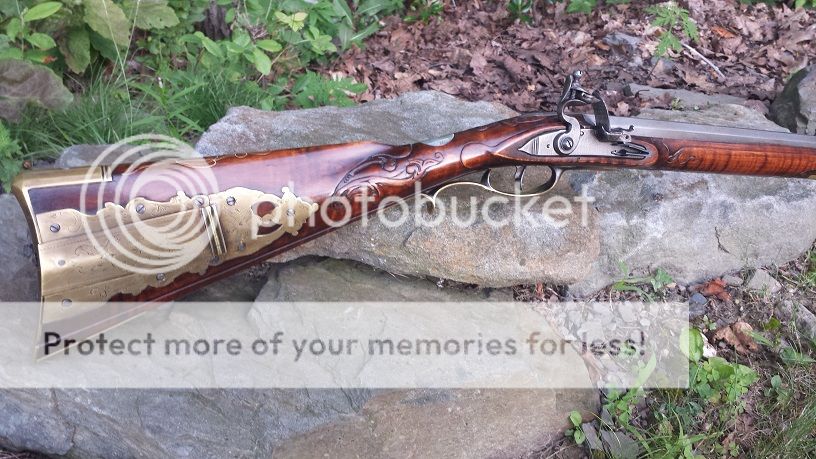

I took a huge leap and dove head first into building a rifle from scratch. I've never built a kit or read any books on gunsmithing but I have been around tools and muzzleloading my entire life.

Here are a few pictures of my progress using what info I could find online and from using measurements of a couple rifles. I have ordered The Gunsmith of Grenville County and will study it thoroughly when it arrives.

Today I start inletting a brass patchbox and am a bit nervous about it :haha:

I'm assuming I should inlet the door and hinge section of the box first and then the two side plates?

Here is a link to the pictures. Cant figure out how to post them here?

Link

I took a huge leap and dove head first into building a rifle from scratch. I've never built a kit or read any books on gunsmithing but I have been around tools and muzzleloading my entire life.

Here are a few pictures of my progress using what info I could find online and from using measurements of a couple rifles. I have ordered The Gunsmith of Grenville County and will study it thoroughly when it arrives.

Today I start inletting a brass patchbox and am a bit nervous about it :haha:

I'm assuming I should inlet the door and hinge section of the box first and then the two side plates?

Here is a link to the pictures. Cant figure out how to post them here?

Link