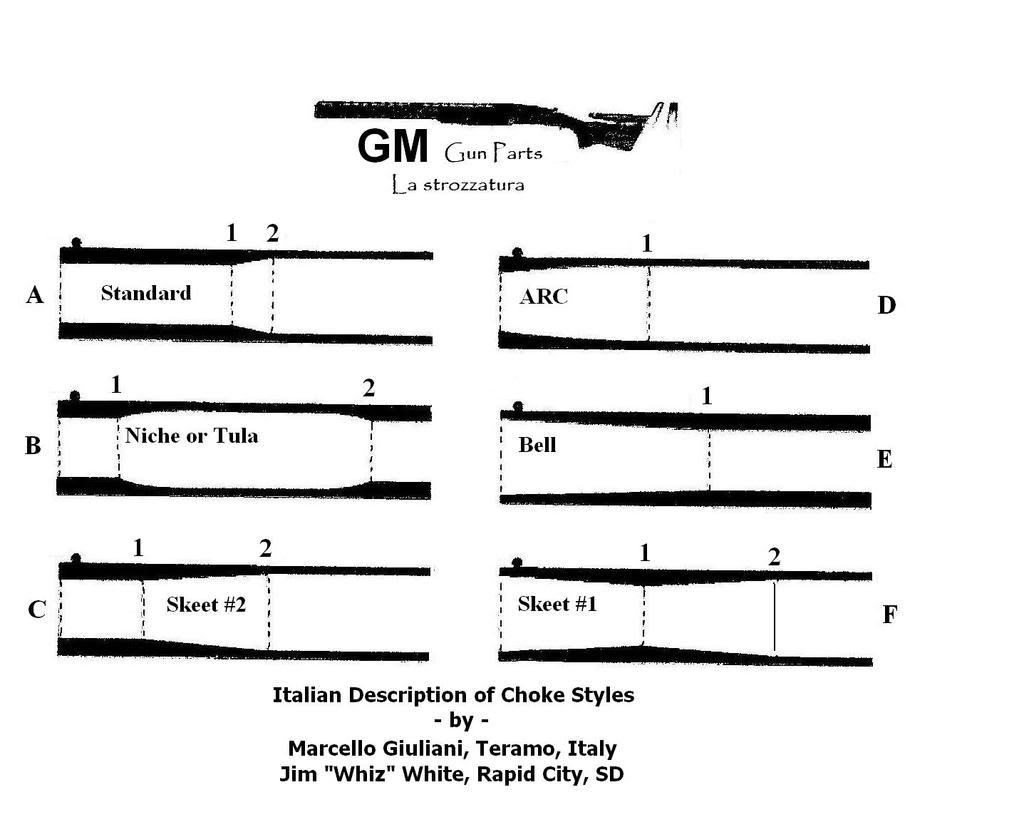

Jug choking is pretty popular these days, it apparently works fairly well, and there's a lot of discussion of it on the forum. Like so many things about our hobby, questions come up as to when it got started, and whether we are HC/PC if we use it in our guns. In a good but long article in a British magazine, The Gun Collector, an explanation of its origins is given which seems well researched, so I thought some of our few history buffs might be interested. Sorry, even the compact version is too long.

In 1869-70 two duck hunters, Fred Kimble of Peoria, Illinois, and Joseph Long of Boston were in a friendly competition in duck shooting and agreed to begin the next season with heavier muzzleloading guns "bored to shoot as close as possible". They worked with their own gunsmiths to develop these guns, and over the next two years came up with some guns which shot amazingly well. They were choked, and in essentially the same way we choke guns today, with the main bore the same diameter up to about two inches from the muzzle, and then constricted to various degrees. Word spread of the prowess of the two hunters with these new guns. In the shop of a gunsmith in Young America, Illinois, a hanger-on named Russell M. Faburn got to examine one of Kimble's guns, and, unable to inspect the entire bore, concluded that it was a recess cut only right behind the muzzle. He invented an adjustable "reamer for boring out shot-gun barrels" to do that and patented it in June of 1872. He named his process choke-boring. He had a successful business of selling the reamers over the next few years in the western states.

So, the date of development of jug-choking, as we call it, was apparently 1871-72, and it occurred in Illinois.

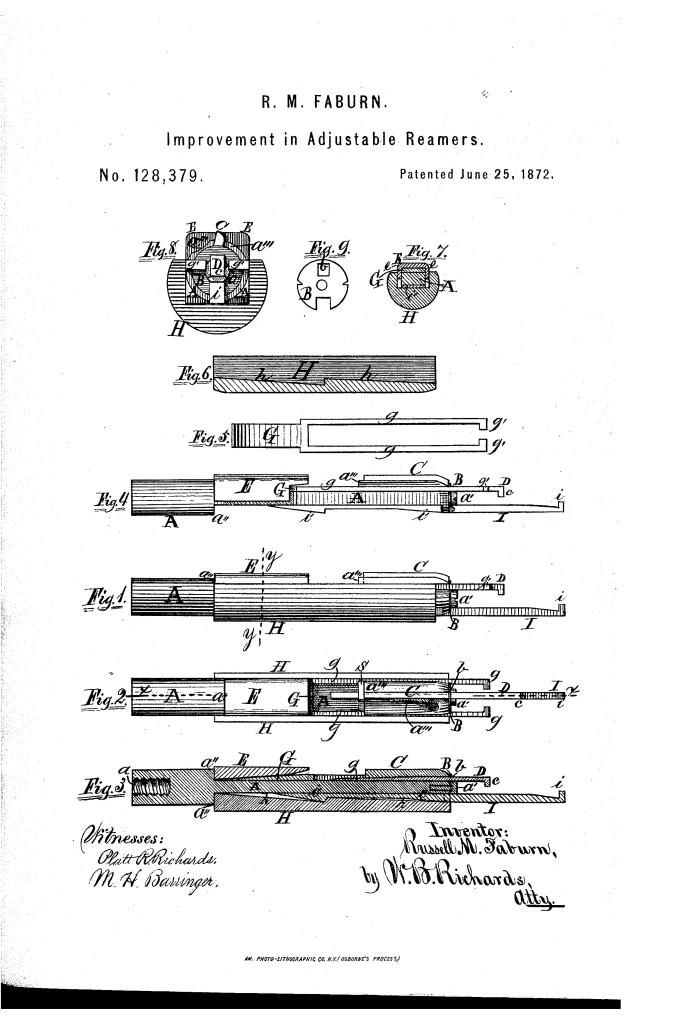

Here are the patent description and illustrations of Faburn's device.

******************

PATENT OFFICE.

RUSSELL M. FABURN, of YOUNG AMERICA, ILLINOIS.

IMPROVEMENT IN ADJUSTABLE REAMERS.

Specification forming part of Letters. Patent No. 128,37 9, dated June 25,1872.

Specification describing certain Improvements in Adjustable Reamers, invented by RUSSELL M. FABURN, of Young America, county of Warren, and State of Illinois.

The nature of my invention relates to a reamer for boring out shot-gun barrels, either with a straight bore or with a bore enlarged at any part, and contracted at either or both ends of the barrel, as desired. The invention consists in making the cutter, the backing, and the follower adjustable to the stock, and in providing devices whereby the adjustment may be effected while the reamer is within the gun-barrel, all as hereinafter fully described.

Figure l is a side elevation of my invention. Fig. 2 is a top view. Fig. 3 is a longitudinal sectional view of Fig. 2 on the line w. Fig. 4 is a side view of Fig. l with the backing removed. Fig. 5 is a top view of one of the adjusting-bars; Fig. 6, a longitudinal sectional view of the wooden backing. Fig. 7 a cross section of Fig. l on the line y y; Fig. 8, an [?] The drawings are all full size, except Fig. 8, which is double size. 1

A is the stock, with a threaded hole, a, at one end, into which the handle is inserted for operating the machine, and with a hole, also, at the other end, into which a screw-bolt, a', is inserted, for the purpose of holding a disk, B, in place. The end of the stock A receiving the handle is enlarged, as shown, leaving a shoulder, a", at the forward end of the enlargement, and the forward end carries a projection, a, having a longitudinal recess in which the knife or cutter C rests. D is an adjusting-bar for the cutter C. It is wedge shaped, as shown, and provided with a hook, c, at its rear end. Its forward end is passed through a hole, b, in the disk B, and also through a hole through the rear end of the projection a, resting between the stock A and the cutter C, so that when it is pushed forward it will raise the cutter, and, when drawn out, will allow the cutter to recede. E is the follower formed in its cross-section, as shown at Fig. 7, with ledges at each side fitting snugly to the stock A, its upper side flat, with the corners e e slightly rounded off. G is a wedge-shaped plate, with two arms, g g, (see Fig. 5,) projecting forward through grooves in the sides of projection a m, and having on their outer ends hooks g g. The wedge G r passes between the follower E and the stock A, (see Figs. 3 and 7,) and may be pushed forward to elevate the follower E, or drawn back to depress the same. H is a wooden backing formed in its cross-section, as shown at Fig. 8, and in its lower part with two inclined planes, h h, as shown at Fig. 6. I is a bar, with a hook, i, on its rear end, and two inclined-plane elevations, t" i', on its forward end, corresponding with the incline planes h h in the backing H, as shown at Fig. 3. It will be seen by the same figure that, pushing the bar I forward, the elevations i" t" will raise the ends of the backing H simultaneously, and withdrawing or pulling it back will allow both ends to recede alike. It will be seen at Fig..8 that the bars D and I rest against the flattened sides of the head of the bolt a', and prevent its shaking loose. It will also be seen at Fig. 9, which shows the disk B alone, that it contains notches through which the adjusting-bars pass, which serve to hold it in place. The cutter O is held in position longitudinally at one end by the upper side of the disk B, and at the other by a bridge, S. (See Fig. 2.)

The operation of my invention is as follows:

The backing, cutter, follower, and adjusting-bars being all in place, the reamer may be inserted in the gun-barrel, and the operator may with a hooked rod reach the adjusting-bars from the end of the barrel forward of the cutter, and either withdraw or push in either bar, as desired, first adjusting the follower and the backing to fit snugly in the barrel, and to preserve the operating handle in the rear, about in the center of the barrel. Then the cutter may be set to trim a light or heavy shaving, as desired, with a rotary motion of the reamer. It will be plainly seen the operation of the reamer is to cut a bore smaller at the muzzle and larger back, as desired. The follower E acts as a guide and as a burnisher.

Having thus described my invention, what I claim as new, and desire to secure by Letters Patent, is-

1. The combination of the adjustable backing H, constructed substantially as described, with the adjusting-bar I fi i', stock A, and follower E, bar G, backing H, bar I, disk B, and screw a', when combined and arranged to operate substantially as and for the purpose I set forth.

RUSSELL M. FABURN. Witnesses:

PLATT R. RICHARDs, M. H. BARRINGER.

****************

Spence

In 1869-70 two duck hunters, Fred Kimble of Peoria, Illinois, and Joseph Long of Boston were in a friendly competition in duck shooting and agreed to begin the next season with heavier muzzleloading guns "bored to shoot as close as possible". They worked with their own gunsmiths to develop these guns, and over the next two years came up with some guns which shot amazingly well. They were choked, and in essentially the same way we choke guns today, with the main bore the same diameter up to about two inches from the muzzle, and then constricted to various degrees. Word spread of the prowess of the two hunters with these new guns. In the shop of a gunsmith in Young America, Illinois, a hanger-on named Russell M. Faburn got to examine one of Kimble's guns, and, unable to inspect the entire bore, concluded that it was a recess cut only right behind the muzzle. He invented an adjustable "reamer for boring out shot-gun barrels" to do that and patented it in June of 1872. He named his process choke-boring. He had a successful business of selling the reamers over the next few years in the western states.

So, the date of development of jug-choking, as we call it, was apparently 1871-72, and it occurred in Illinois.

Here are the patent description and illustrations of Faburn's device.

******************

PATENT OFFICE.

RUSSELL M. FABURN, of YOUNG AMERICA, ILLINOIS.

IMPROVEMENT IN ADJUSTABLE REAMERS.

Specification forming part of Letters. Patent No. 128,37 9, dated June 25,1872.

Specification describing certain Improvements in Adjustable Reamers, invented by RUSSELL M. FABURN, of Young America, county of Warren, and State of Illinois.

The nature of my invention relates to a reamer for boring out shot-gun barrels, either with a straight bore or with a bore enlarged at any part, and contracted at either or both ends of the barrel, as desired. The invention consists in making the cutter, the backing, and the follower adjustable to the stock, and in providing devices whereby the adjustment may be effected while the reamer is within the gun-barrel, all as hereinafter fully described.

Figure l is a side elevation of my invention. Fig. 2 is a top view. Fig. 3 is a longitudinal sectional view of Fig. 2 on the line w. Fig. 4 is a side view of Fig. l with the backing removed. Fig. 5 is a top view of one of the adjusting-bars; Fig. 6, a longitudinal sectional view of the wooden backing. Fig. 7 a cross section of Fig. l on the line y y; Fig. 8, an [?] The drawings are all full size, except Fig. 8, which is double size. 1

A is the stock, with a threaded hole, a, at one end, into which the handle is inserted for operating the machine, and with a hole, also, at the other end, into which a screw-bolt, a', is inserted, for the purpose of holding a disk, B, in place. The end of the stock A receiving the handle is enlarged, as shown, leaving a shoulder, a", at the forward end of the enlargement, and the forward end carries a projection, a, having a longitudinal recess in which the knife or cutter C rests. D is an adjusting-bar for the cutter C. It is wedge shaped, as shown, and provided with a hook, c, at its rear end. Its forward end is passed through a hole, b, in the disk B, and also through a hole through the rear end of the projection a, resting between the stock A and the cutter C, so that when it is pushed forward it will raise the cutter, and, when drawn out, will allow the cutter to recede. E is the follower formed in its cross-section, as shown at Fig. 7, with ledges at each side fitting snugly to the stock A, its upper side flat, with the corners e e slightly rounded off. G is a wedge-shaped plate, with two arms, g g, (see Fig. 5,) projecting forward through grooves in the sides of projection a m, and having on their outer ends hooks g g. The wedge G r passes between the follower E and the stock A, (see Figs. 3 and 7,) and may be pushed forward to elevate the follower E, or drawn back to depress the same. H is a wooden backing formed in its cross-section, as shown at Fig. 8, and in its lower part with two inclined planes, h h, as shown at Fig. 6. I is a bar, with a hook, i, on its rear end, and two inclined-plane elevations, t" i', on its forward end, corresponding with the incline planes h h in the backing H, as shown at Fig. 3. It will be seen by the same figure that, pushing the bar I forward, the elevations i" t" will raise the ends of the backing H simultaneously, and withdrawing or pulling it back will allow both ends to recede alike. It will be seen at Fig..8 that the bars D and I rest against the flattened sides of the head of the bolt a', and prevent its shaking loose. It will also be seen at Fig. 9, which shows the disk B alone, that it contains notches through which the adjusting-bars pass, which serve to hold it in place. The cutter O is held in position longitudinally at one end by the upper side of the disk B, and at the other by a bridge, S. (See Fig. 2.)

The operation of my invention is as follows:

The backing, cutter, follower, and adjusting-bars being all in place, the reamer may be inserted in the gun-barrel, and the operator may with a hooked rod reach the adjusting-bars from the end of the barrel forward of the cutter, and either withdraw or push in either bar, as desired, first adjusting the follower and the backing to fit snugly in the barrel, and to preserve the operating handle in the rear, about in the center of the barrel. Then the cutter may be set to trim a light or heavy shaving, as desired, with a rotary motion of the reamer. It will be plainly seen the operation of the reamer is to cut a bore smaller at the muzzle and larger back, as desired. The follower E acts as a guide and as a burnisher.

Having thus described my invention, what I claim as new, and desire to secure by Letters Patent, is-

1. The combination of the adjustable backing H, constructed substantially as described, with the adjusting-bar I fi i', stock A, and follower E, bar G, backing H, bar I, disk B, and screw a', when combined and arranged to operate substantially as and for the purpose I set forth.

RUSSELL M. FABURN. Witnesses:

PLATT R. RICHARDs, M. H. BARRINGER.

****************

Spence