So after 3-4 range sessions I am close enough with my load development for the Hoyt barrel. Im ready to take her apart and to some minor stock shaping and metal part sanding. I am tempted to leave the barrel and metal parts unfinished.

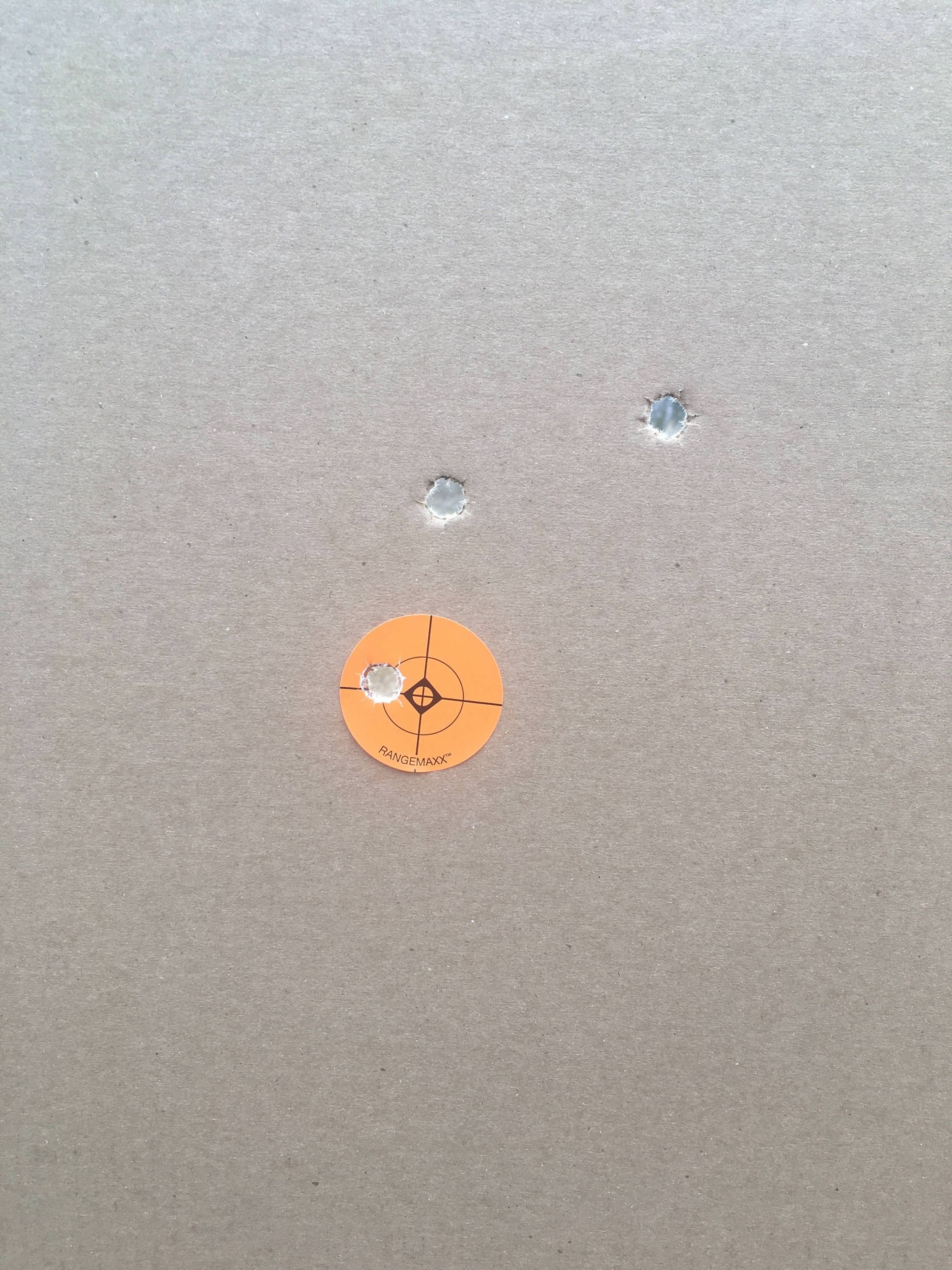

With 90 grains of GOEX FFG and pillow ticking cut at the muzzle with 7:1 oil mix shooting at 50 yards off the bench this is what I got.

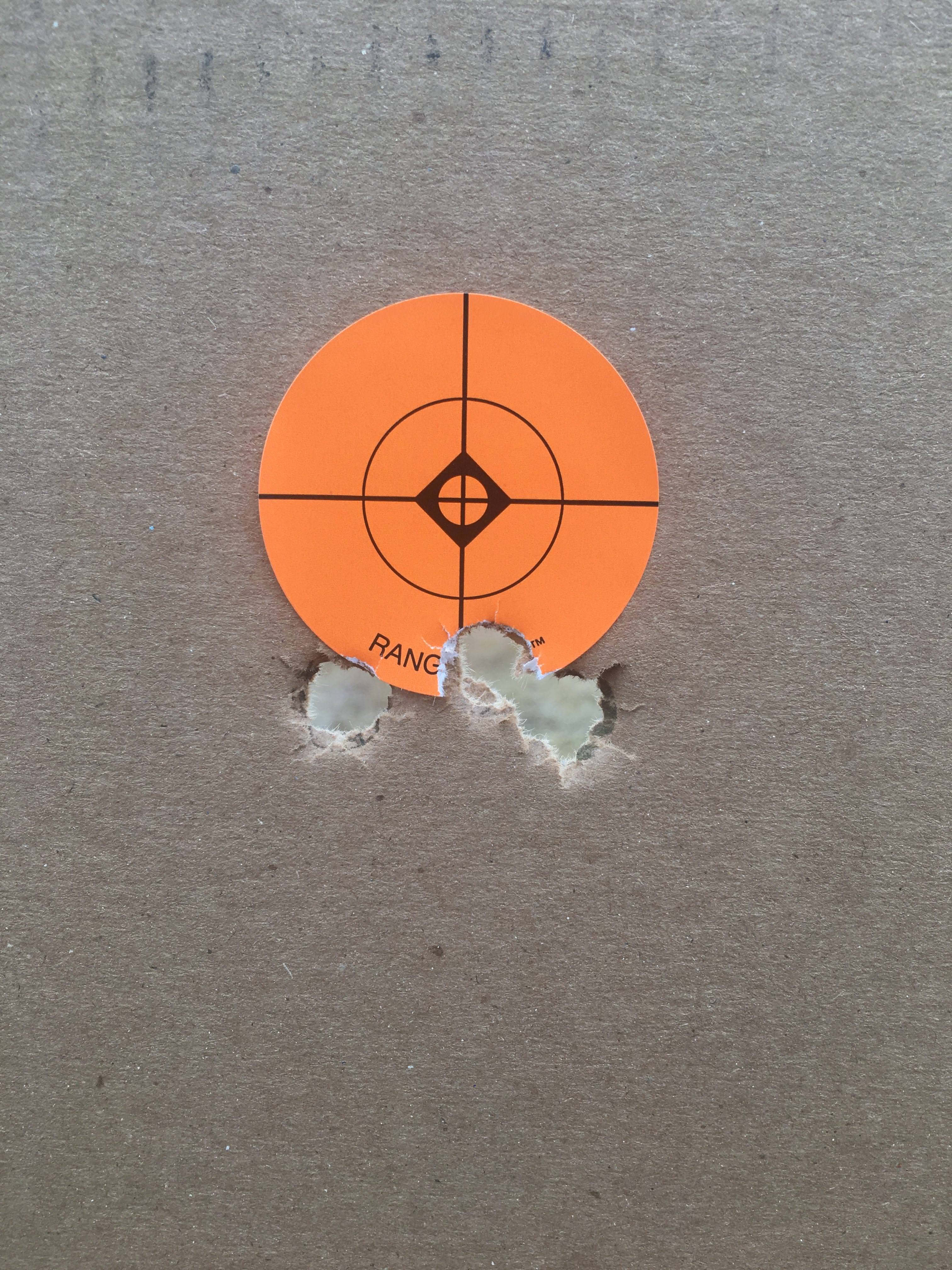

I decided to start over at 70 Grains and same patch combo.

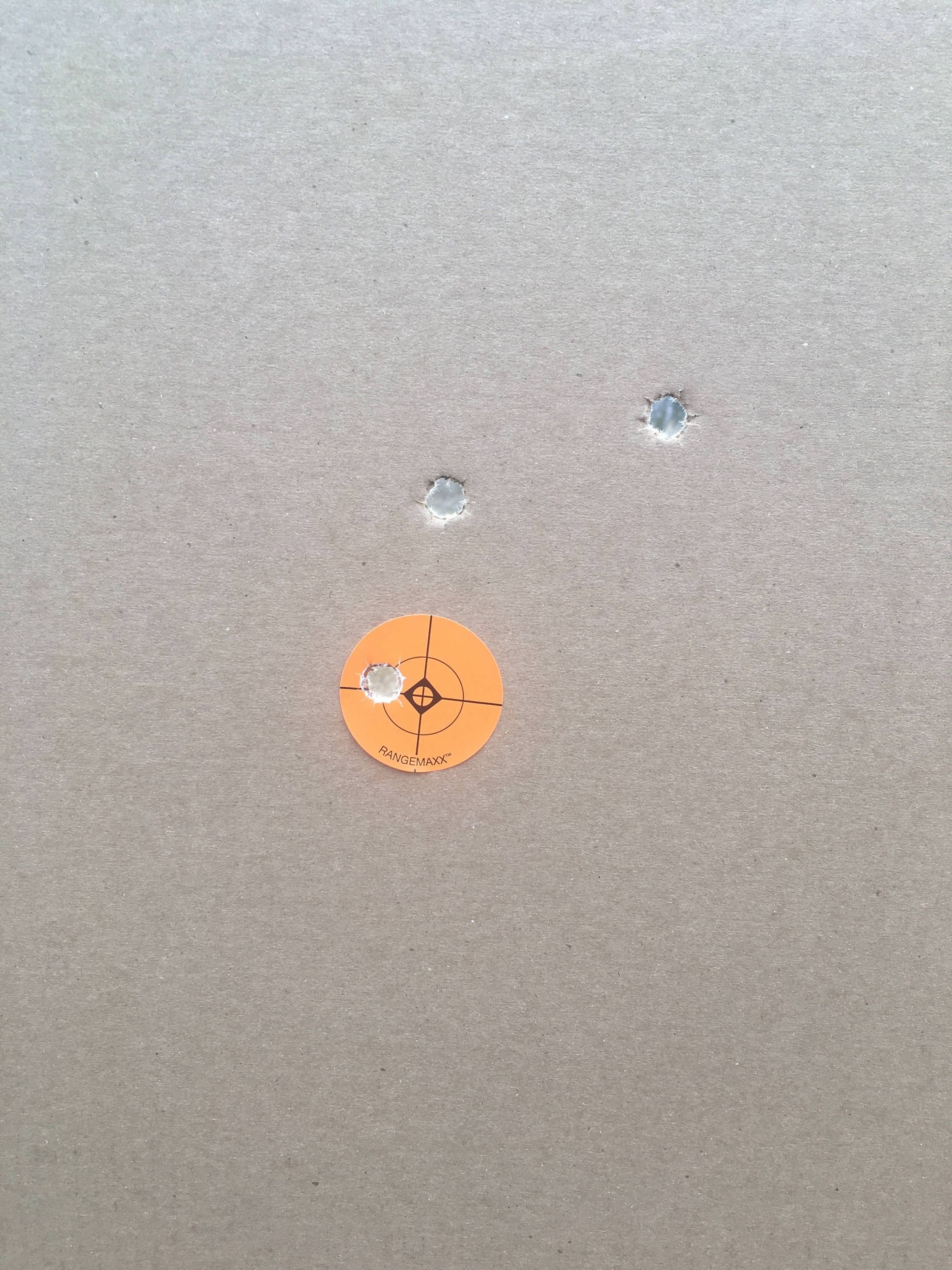

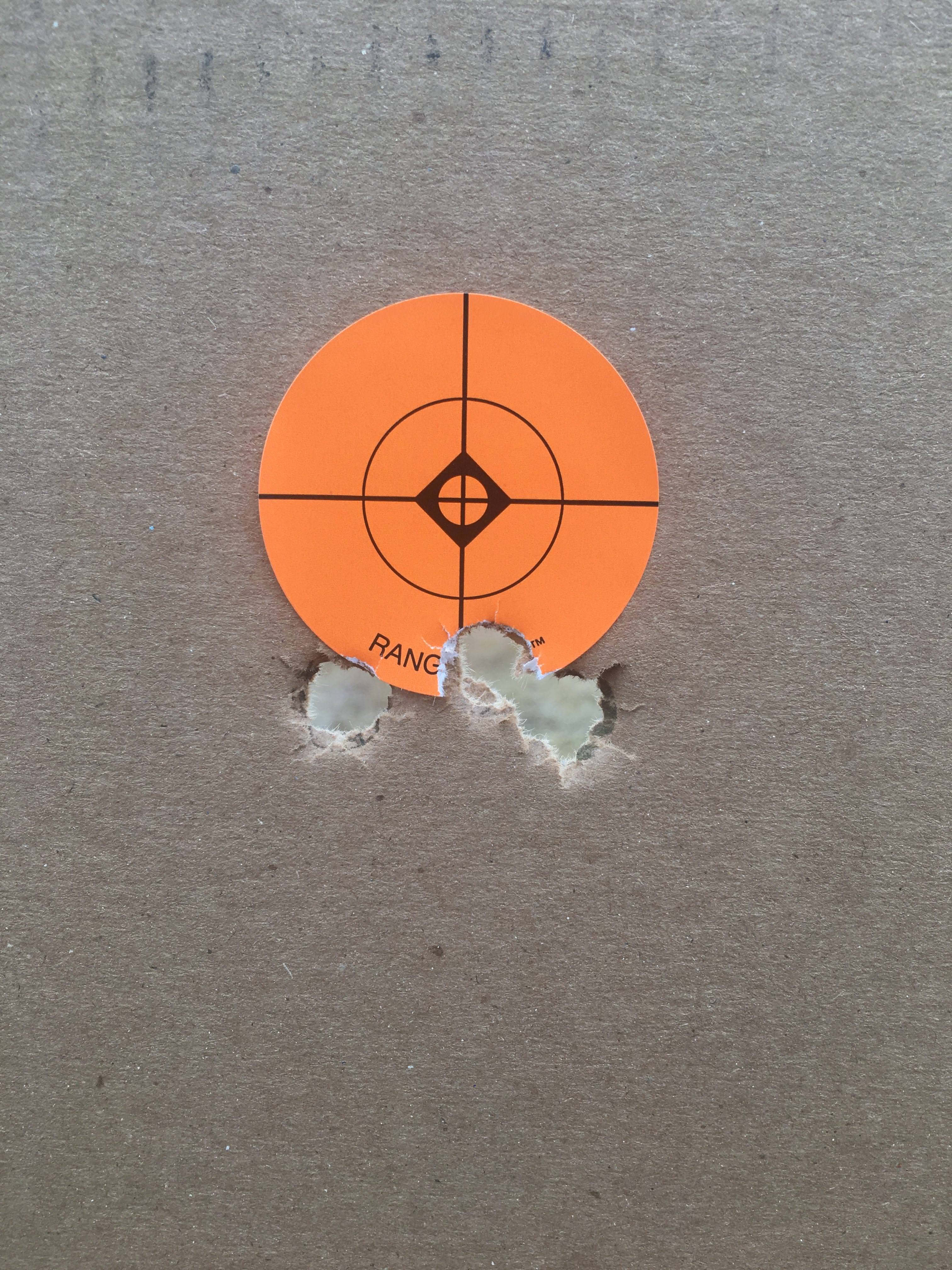

Then I repeated just to make sure before I wrapped up the range session.

I also modified TC triggerguard to fit a Lyman stock

Attempted to solder it and the joint broke when I stressed it by bending.

I then decided to use silver solder and it resulted in a super strong joint that I am accustomed with.

With 90 grains of GOEX FFG and pillow ticking cut at the muzzle with 7:1 oil mix shooting at 50 yards off the bench this is what I got.

I decided to start over at 70 Grains and same patch combo.

Then I repeated just to make sure before I wrapped up the range session.

I also modified TC triggerguard to fit a Lyman stock

Attempted to solder it and the joint broke when I stressed it by bending.

I then decided to use silver solder and it resulted in a super strong joint that I am accustomed with.