Gordoncourtney

50 Cal.

- Joined

- Feb 19, 2021

- Messages

- 1,359

- Reaction score

- 2,429

Probably best string for this

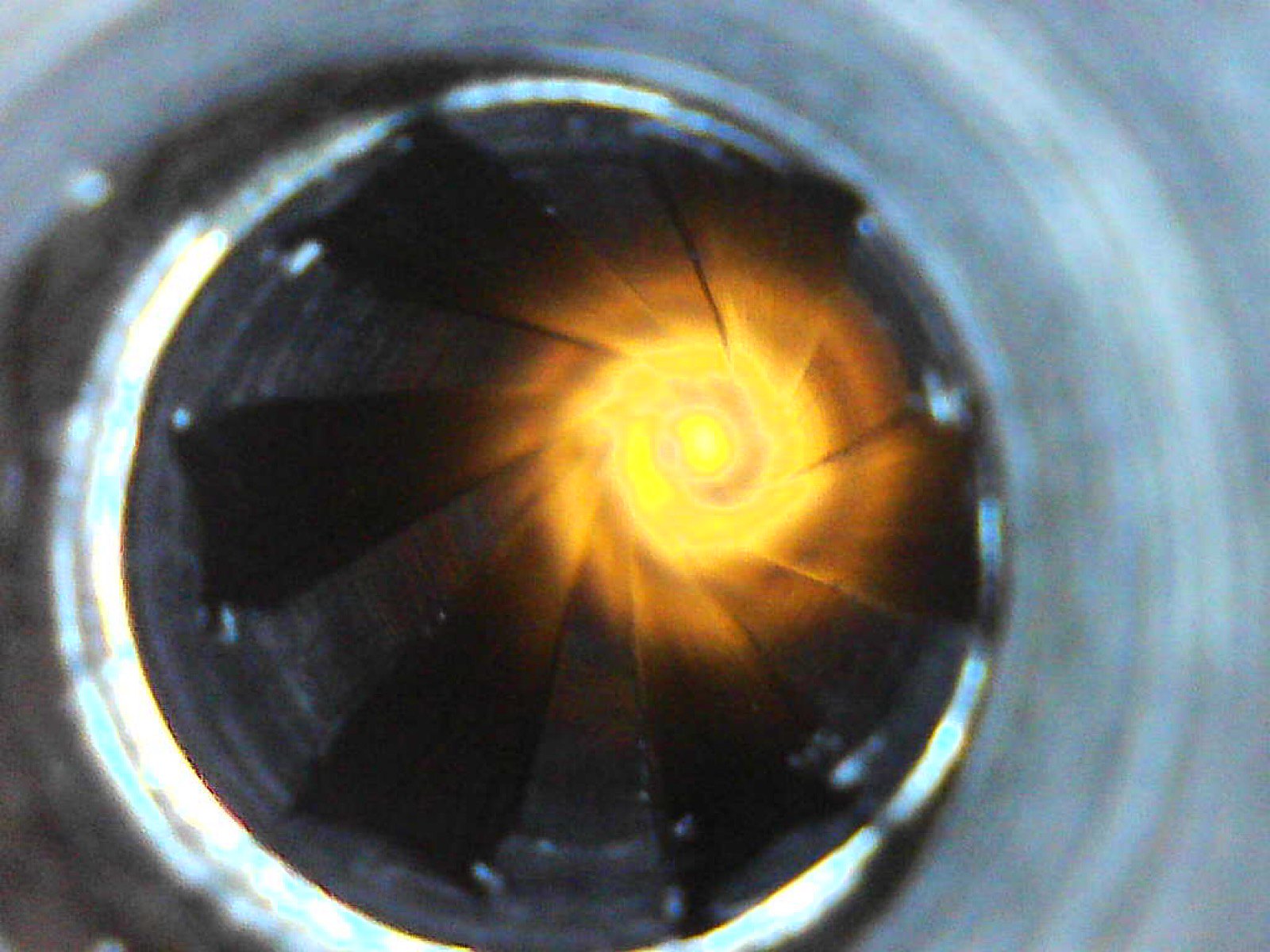

I had a two grove 1850 .6 barrel nothing of value but I wanted to add extra groves. I am a nutter from the 1960s. You could not buy much then so you had to make it

The cutter I made out of paring off lathe tool

Steel. After hours I manage to make a hole using dremmil and diamond engravers

15 mm copper tube fitted the bore so I soldered on two brass runners to fit the two groves. Filed till it rotated smoothly up and down barrel

For the cutter the above tool steel was pinned and held in a steel rod inside the copper tube. I drilled some holes at the other so with the drill I could accurately twist the steel inside the copper tube. To raise the cutter I just stuffed elastic bands under the cutter

It was slow scraping but made beautiful groves not fired it yet. More fun for the challenge.

You can do it with any barrel to refresh them as long as your riffling will hold a runner whilst the cutter cleans out the old grove

I wish you well

I had a two grove 1850 .6 barrel nothing of value but I wanted to add extra groves. I am a nutter from the 1960s. You could not buy much then so you had to make it

The cutter I made out of paring off lathe tool

Steel. After hours I manage to make a hole using dremmil and diamond engravers

15 mm copper tube fitted the bore so I soldered on two brass runners to fit the two groves. Filed till it rotated smoothly up and down barrel

For the cutter the above tool steel was pinned and held in a steel rod inside the copper tube. I drilled some holes at the other so with the drill I could accurately twist the steel inside the copper tube. To raise the cutter I just stuffed elastic bands under the cutter

It was slow scraping but made beautiful groves not fired it yet. More fun for the challenge.

You can do it with any barrel to refresh them as long as your riffling will hold a runner whilst the cutter cleans out the old grove

I wish you well

Attachments

-

7CA2D581-4153-410B-9BFD-2BBD5E8785CA.jpeg1.2 MB

7CA2D581-4153-410B-9BFD-2BBD5E8785CA.jpeg1.2 MB -

C07596F7-B956-4054-B3C3-F7D79460223D.jpeg930.9 KB

C07596F7-B956-4054-B3C3-F7D79460223D.jpeg930.9 KB -

ED56A4BD-A7C2-4CA2-8545-584E4C331C83.jpeg1.2 MB

ED56A4BD-A7C2-4CA2-8545-584E4C331C83.jpeg1.2 MB -

C4FE464B-B141-4610-AF4D-262505131997.jpeg1.3 MB

C4FE464B-B141-4610-AF4D-262505131997.jpeg1.3 MB -

E8117203-2973-4E0D-8D7E-FC7404CFB178.jpeg1.5 MB

E8117203-2973-4E0D-8D7E-FC7404CFB178.jpeg1.5 MB -

9FD42AD0-7BF9-49BC-9802-E464EB756616.jpeg1.2 MB

9FD42AD0-7BF9-49BC-9802-E464EB756616.jpeg1.2 MB -

233D9EE6-781D-4AE7-A0A8-39D721B030A9.jpeg1,009.6 KB

233D9EE6-781D-4AE7-A0A8-39D721B030A9.jpeg1,009.6 KB -

21DB45DB-B6D9-4689-976B-EDF0C2237C45.jpeg1.6 MB

21DB45DB-B6D9-4689-976B-EDF0C2237C45.jpeg1.6 MB -

56FDB28D-82C3-41F1-996D-98867C1A951C.jpeg3.4 MB

56FDB28D-82C3-41F1-996D-98867C1A951C.jpeg3.4 MB