kelvinator said:

Thanks all. Ohio ramrod, just a question and please excuse my lack of knowledge. What is this "leather over powder wad" thing about ? Thats something I'm not familiar with, except for shotgun ? And FFF, the instructions that came with the barrel said use only FF or equiv. Guess I should be inquiring about break-in procedures as well.

Thanks again.

Hey buddy,

I shoot several of Greenmtnbarrels from 36 cal to 54 and get MOA(one inch groups) at 100 yrds with all of them.

Here is how do it, you do it this way and your gun WILL! shoot MOA I promise.

First get Neco lapping compound(on line)

Lapp your barrel by putting lapping compound on a shooting patch .018(start with 220 grit).

start a ball and patch with compound on it and run it to the breach.

Put a ball puller on your 7/16 ranger rod start it into the ball and saw back and forth hitting the front of the barrel the most maby 40 times.Patch clean your barrel between Lapping with Hoppies # 9 to get all lapping residue out.

Do this three times for every grit, takes three hours.

Your barrel is now lapped in and ready to shoot.

Unless you got a rough barrel and if you did check now before you do all that work.

GMB have gone down hill in the last two years but I heard they are getting their crap back together.

If your barrel is very rough, SEND IT BACK!

OK now it's patch time.I don't give a hoot as to what every body else says After thousands of rounds through my competition rifles I have settled on two patches and ball combo's that will give you MOA.

Go to wall mart with your Calipers and get .030 and .028 canvas at the sewing dept.

The .030 is tan the .028 is white, it also comes in a couple different colors but mainly white.

Use this patch with a .010 under ball(what cal are you shooting?) and you will get great accuracy.

Wet lube

This is what you will use to get your gun most center at 50 yrds.

I use Lehigh lube when I can find it but I found six parts water one part Ballistol(from midway) and one part Murphy oil gets me as good accuracy.

For fine rifle tuning wile using a wet patch I swab between shots for consistency.

I wring most all moisture out of my wet patch before loading.

You can get MOA with a wet patch but for serious accuracy I use a Greased patch(elk tallow,Marmot oil) for hunting and a dry patch for bench rest work.

Dry patch.

Get Dutch Schultz's book on dry patch shooting.

It's the bible on dry patch(on line).

I can't go in to that much detail here.

Any way that will get you started.

Greenmtnbarrels are some of the most accurate I have ever shot including their fast twist conical barrels.

If you are shooting a 40 cal or 36 cal use fffG and a .020 canvas patch from Texas patching(on line) and a .005 thousands under size ball.

I use ffg for 45 cal and above.

NEVER use a over powder wad in you GMB your accuracy will go south.

I spent a whole winter trying to squeeze more accuracy out of my barrels and one thing I tried was a over powder wad, they don't work.

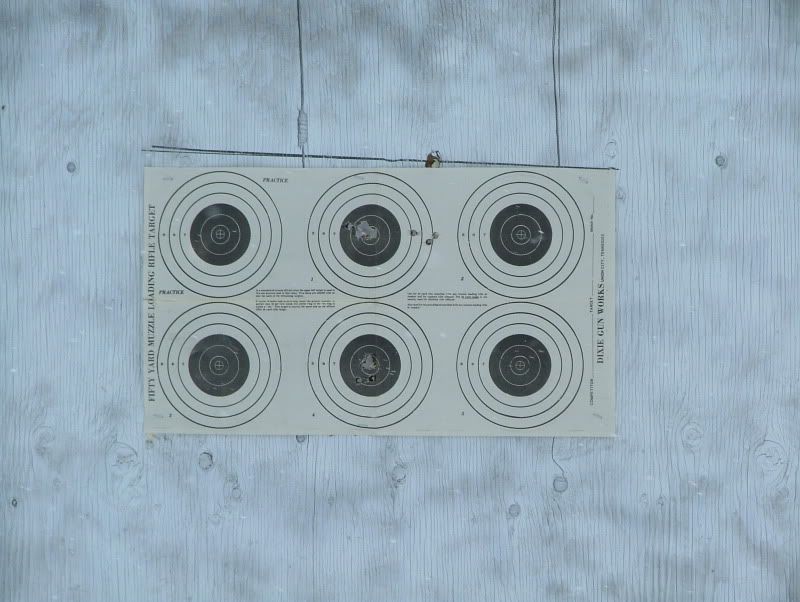

Here are a couple 100 yrd targest

one is a 40 cal, it was the last day I was siting it in.

first three were to the right, then I did a slight site ajustment and I setteled down to shoot two groups of five using the .020 texas patch.

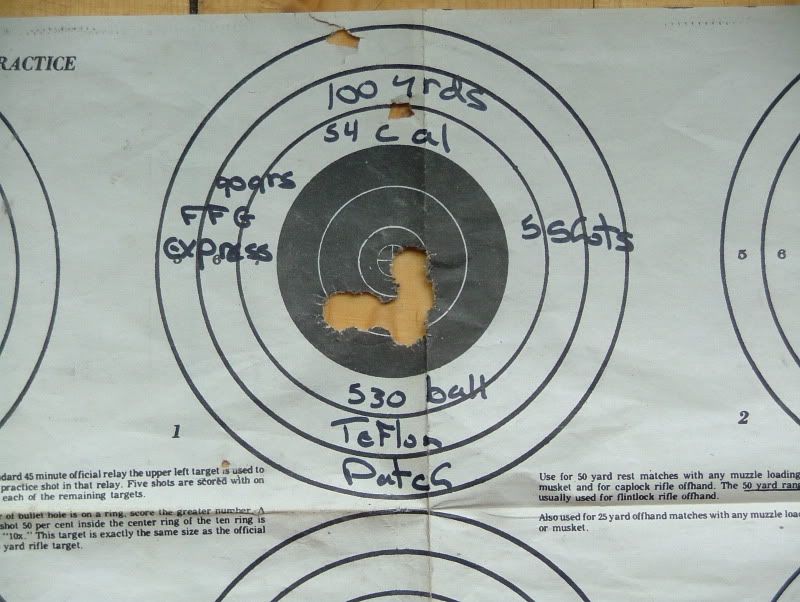

The next is my standard 54 cal load for all three of my 54s with GMB