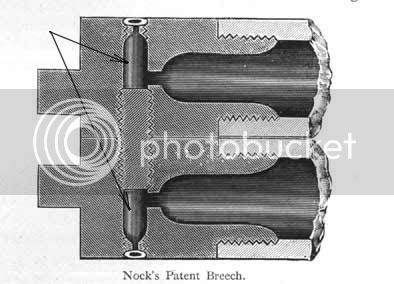

There are, basically, two different style Breeches being sold by commercial gun makers here in the USA: The Nock-style Patent Breech- with its reduced size powder chamber, comes with most all guns imported in whole or as parts from Europe, and the T/C rifles. ( Lyman, Investment arms, Pedersoli, etc.)

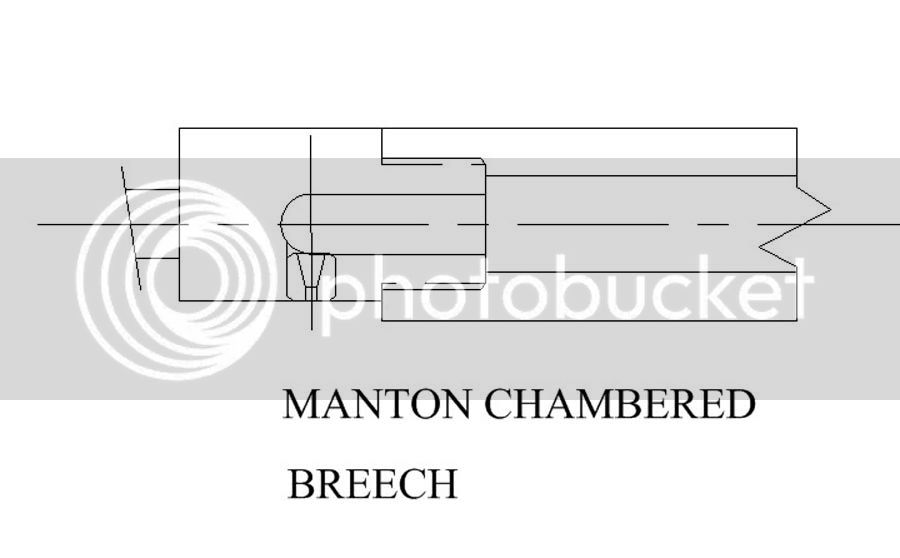

The other Breech is a " Flat Breech", where the breech is located 1/8" to the rear of the TH. The vent hole from the flash pan into the barrel goes directly into the barrel from the side, rather than running down a small flash channel, turning at right angles, to go through a small hole into the powder chamber.

When you know what your gun has, there is no problem figuring out how to make it fire reliably. My only complain with the Nock Style Patent breeches is that the companies who use them don't do a good enough job telling the buyer that its in his gun, Nor do they tell the shooter what the diameter of that powder chamber is, so he can acquire the correct sized jags to clean it!

The manufacturers seem to thing that because the powder chamber is smaller than the bore, that it "burns itself clean" with each shot fired. That is Not my experience with these guns, nor the experience of dozens of club members who have shot these guns over the years.

The problem with keeping these chambers, and small flash channels clean is compounded by using any petroleum based oils in those parts. But, any oil, left in those small channels, can create an obstruction sufficient to block the movement of powder through the flash channel to the TH, where the presence of powder at the mouth of the TH is essential for consistent ignition.

Normally, the air between your PRB and the powder charge in the barrel, will push some powder ahead of it as it escapes out the TH, as the PRB is driven down the barrel onto the powder charge. If there is oil in the chamber, or in the small channels, you get gummy "clumps" of powder that will not ignite well, or easily, and cannot move through the flash channel to the TH.

Worse, if they plug the small hole at the back of the powder chamber, they can prevent ANY powder from moving to the TH. The air instead escapes up the grooves of the rifling. Some shooters report experiencing " dieseling", where their PRB comes back up off the powder, when they release the pressure on their ramrods, due to trapped air between the powder charge and the PRB. :hmm:

That can create a "bore obstruction" in the barrel of an unaware shooter. :nono:

It must have caused the excess solvent to wet the breech excessively, or enough to dampen any powder loaded for a subsequent shot. I have a few flinter tools which each have vent picks, but these were no good when this happened.

It must have caused the excess solvent to wet the breech excessively, or enough to dampen any powder loaded for a subsequent shot. I have a few flinter tools which each have vent picks, but these were no good when this happened.