You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking to improve accuracy

- Thread starter flyfish

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

My Investarms cabelas rifles LOVE the 385 gr conicals and I was getting 2" or better at 100 yds when I shot em. Im PRB guy now (till I draw bull buffalo tag then will rethink). Try different lubes in addition to that they come with then up and down with the powder 5 gr at a time. Mine love 70 gr. BTW when ya have a sting of bad range days as I have in the past its hard to keep at it. Another memeber is/was getting excellent groups in his .40 then he suddenly cant repeat em? Bad days do run in strings. Hang in there. And save then sugar maples!

ravenousfishing

40 Cal.

- Joined

- Sep 19, 2007

- Messages

- 260

- Reaction score

- 22

Lots of good advice given above. Another thing to keep in mind is that deer dont always react to hits from roundballs the same way they do with modern rifles and bullets. Make no mistake about it though, they are plenty lethal when placed properly, just like a bow.

When I got into muzzleloading hunting in 2007, I took a shot at a doe at 25 yds. When the smoke cleared I couldn't believe she wasn't laying in a heap where she had been standing. After looking for blood for 15 min, I gave up and went back to my stand, figuring I must have missed somehow. I managed to shoot a spike that came into the field about 30 min later so I went home happy.

However, I still couldn't get over that "miss". I started doing some research, ( much of it on this site), and came to realize that there often isn't a blood trail for 40-50 yds, even with a perfect double lung shot. From that day on, I've learned that if I think I made a good shot, I probably did. I just keep looking, eventually finding blood, or in one case, a dead deer with absolutely no blood trail for all but the last 5 yds of a 75 yd run. Confidance in your rifle and load allows confidance in your shot placement. Good luck in working up an accurate load for your rifle. I'm sure you'll be pleased.

When I got into muzzleloading hunting in 2007, I took a shot at a doe at 25 yds. When the smoke cleared I couldn't believe she wasn't laying in a heap where she had been standing. After looking for blood for 15 min, I gave up and went back to my stand, figuring I must have missed somehow. I managed to shoot a spike that came into the field about 30 min later so I went home happy.

However, I still couldn't get over that "miss". I started doing some research, ( much of it on this site), and came to realize that there often isn't a blood trail for 40-50 yds, even with a perfect double lung shot. From that day on, I've learned that if I think I made a good shot, I probably did. I just keep looking, eventually finding blood, or in one case, a dead deer with absolutely no blood trail for all but the last 5 yds of a 75 yd run. Confidance in your rifle and load allows confidance in your shot placement. Good luck in working up an accurate load for your rifle. I'm sure you'll be pleased.

Will5a1

Thank you for the kind words.

If an over powder wad solves your accuracy problem it indicates that the wad is completing the seal that your too thin patching isn't providing.

The goal is to keep all the gases of the explosion behind the patched ball and not allow any to bypass it on the way out.

Merry Christmas

Dutch

Thank you for the kind words.

If an over powder wad solves your accuracy problem it indicates that the wad is completing the seal that your too thin patching isn't providing.

The goal is to keep all the gases of the explosion behind the patched ball and not allow any to bypass it on the way out.

Merry Christmas

Dutch

Walks with fire

54 Cal.

The 1/32 twist might shoot them well if you get the charge size and components right. I have a 24" barrel in .50 caliber with 1/28 twist that shoots ball good with 90 grains of Goex 2f. I have a 28" long barrel that is the same except 4" longer and it won't shoot a ball worth a hoot. Why; I have no idea.

ohio ramrod

75 Cal.

- Joined

- Aug 21, 2008

- Messages

- 7,473

- Reaction score

- 2,209

another vote for Dutch's system. He will save you many hours of trial and error. :idunno:

Rat Trapper

62 Cal.

- Joined

- Nov 28, 2006

- Messages

- 2,648

- Reaction score

- 7

The twist of your rifle is too fast for patch round balls and heavy hunting loads. A felt wad under those Hornady great plains bullets will help. In my TC Hawken 50 cal my load is 90 grains of Triple Seven 2F. Conicals have always shot better for me with heavier loads. Those fast twist 1-28 & 1-32 barrels shoot best with conicals and sabots. Barrels with 1-48 and slower work well with pRBs.

There's a lot of unmentioned rules-of-thumb being applied here.

One of the old rules is/was: "Twist rates faster than 1:48 have accuracy problems with patched round ball and large powder loads." A lot of folks go further, saying, "A slower twist rate [slower than 1:48] is better for a patched round ball when using large powder loads". A corollary rule is "Conical bullets don't shoot well from slow twist barrels [slower than 1:48]"

The "skipping" across lands and grooves problem, which is often cited as the reason for the above rule-of-thumb, is in reality a factor of very heavy hunting loads with a patched round ball in .54 caliber and larger. (source: The Sporting Rifle and Its Projectiles, by Forsyth) We're talking more in the 140 grain category, not the 70-90 grain range. Now it's true, a slower twist rate for a round ball barrel has advantages when one is not using very heavy loads....ease of loading, ease of loading more than one shot without swabbing, less torque on the shooter when using hunting loads, and quicker cleaning. (Source: Instruction for The Formation and Exercise of Volunteer Sharpshooters, Barber)

So for example 1:48 was for a long time called a compromise twist rate for both round ball and conicals, BUT we now know that a lot of rifles were made with that twist rate prior to the conical bullet becoming popular. Today, a Green Mountain barrel in .40 caliber is 1:56, BUT a Rice barrel or Colerain barrel in the same caliber only comes in 1:48. So the caliber appears to influence the twist rate choice too.

Further along those lines, the 1:24 twist rate on the Pedersoli Jaeger rifle is faster than on your rifle, BUT the recommended bullet is a PRB. Pedersoli also makes several rifles in a 1:72 twist rate that are repros of Civil War muskets...and they shoot conical minnie balls very well. So it may be more than simply the twist rate when it comes to accuracy in a particular rifle.

A rule of thumb that may benefit you is to begin with grains of powder equal to your caliber. So as suggested in some previous posts, reduce your load to 50 grains. Work up or down from there.

You need to try and shoot from a a good, solid rest, to really determine the accuracy, and you need to examine your patches after several shots. I prefer to shoot from a supported, sandbagged position on a bench.

I've not really seen the lube make that much of a difference, unless you are working for maximum accuracy for targets at say 100 yards, and the difference between a hit in the 9 ring or a 10 ring will be the difference between winning and going home empty handed. Others may disagree, but I've found the different lubes for me are more for ease of loading, and weather resistance, than accuracy, but I rarely do serious target shooting. For hunting, the difference between a "clover leaf" group and a 4" group at 100 yards won't matter to a Big Game animal.

The patches, the substance, the thickness, the method, and what happens after firing, will tell you a lot about what is happening if you don't have satisfactory groups. If they are destroyed, or burned through in spots, they may be too thin, or you may have sharp spots on your lands that are cutting the patches or both. Lube may help reduce this, but really your patches on a round ball should survive without holes even if you loaded a patched ball with a dry, cloth patch.

Part of the fun, in this game, is working to get the most out of your rifle (imho).

LD

One of the old rules is/was: "Twist rates faster than 1:48 have accuracy problems with patched round ball and large powder loads." A lot of folks go further, saying, "A slower twist rate [slower than 1:48] is better for a patched round ball when using large powder loads". A corollary rule is "Conical bullets don't shoot well from slow twist barrels [slower than 1:48]"

The "skipping" across lands and grooves problem, which is often cited as the reason for the above rule-of-thumb, is in reality a factor of very heavy hunting loads with a patched round ball in .54 caliber and larger. (source: The Sporting Rifle and Its Projectiles, by Forsyth) We're talking more in the 140 grain category, not the 70-90 grain range. Now it's true, a slower twist rate for a round ball barrel has advantages when one is not using very heavy loads....ease of loading, ease of loading more than one shot without swabbing, less torque on the shooter when using hunting loads, and quicker cleaning. (Source: Instruction for The Formation and Exercise of Volunteer Sharpshooters, Barber)

So for example 1:48 was for a long time called a compromise twist rate for both round ball and conicals, BUT we now know that a lot of rifles were made with that twist rate prior to the conical bullet becoming popular. Today, a Green Mountain barrel in .40 caliber is 1:56, BUT a Rice barrel or Colerain barrel in the same caliber only comes in 1:48. So the caliber appears to influence the twist rate choice too.

Further along those lines, the 1:24 twist rate on the Pedersoli Jaeger rifle is faster than on your rifle, BUT the recommended bullet is a PRB. Pedersoli also makes several rifles in a 1:72 twist rate that are repros of Civil War muskets...and they shoot conical minnie balls very well. So it may be more than simply the twist rate when it comes to accuracy in a particular rifle.

A rule of thumb that may benefit you is to begin with grains of powder equal to your caliber. So as suggested in some previous posts, reduce your load to 50 grains. Work up or down from there.

You need to try and shoot from a a good, solid rest, to really determine the accuracy, and you need to examine your patches after several shots. I prefer to shoot from a supported, sandbagged position on a bench.

I've not really seen the lube make that much of a difference, unless you are working for maximum accuracy for targets at say 100 yards, and the difference between a hit in the 9 ring or a 10 ring will be the difference between winning and going home empty handed. Others may disagree, but I've found the different lubes for me are more for ease of loading, and weather resistance, than accuracy, but I rarely do serious target shooting. For hunting, the difference between a "clover leaf" group and a 4" group at 100 yards won't matter to a Big Game animal.

The patches, the substance, the thickness, the method, and what happens after firing, will tell you a lot about what is happening if you don't have satisfactory groups. If they are destroyed, or burned through in spots, they may be too thin, or you may have sharp spots on your lands that are cutting the patches or both. Lube may help reduce this, but really your patches on a round ball should survive without holes even if you loaded a patched ball with a dry, cloth patch.

Part of the fun, in this game, is working to get the most out of your rifle (imho).

LD

Tom Compton

54 Cal.

- Joined

- Oct 21, 2008

- Messages

- 1,893

- Reaction score

- 193

Discussion of twist an PRB vs conical cannot be complete without including the depth of rifling. The shallow groove button rifling of the TC barrels would not hold or adequately grip a .490 ball and .010 patch when loading heavy loads like 100 gr FFFg. They would work w conicals loaded like an real and because of the increased surface area contact of multiple bands all of which are wider than the tangent of a PRB.

TC

TC

Tom Compton

54 Cal.

- Joined

- Oct 21, 2008

- Messages

- 1,893

- Reaction score

- 193

Right that shallow rifling don't hold that .490 RB real well with a .010 patch but up that patch thickness to .020 and it will do just fine and if your muzzle is crowned real good or has a good cone job it won't be much harder to load. I have a 54 cal shallow groove and was not able to get better than a 3" group at 50yds with 80grns FFg Daryl told me to try the thicker patch and now it will shoot 1 1/2" groups at 50 yds with 90grns powder and 100yds groups are as good as the 50yds used to be,and this is a 28" long barrel. :thumbsup:

I left some things out of my previous reply,I meant to say if the barrel has the applicable twist but has shallow grooves then the tighter patch will really improve accuracy. The 54 cal rifle i was reffering to has a barrel with 1/48 twist but shallow rifling.

There are a number of things here.

First. Define shallow grooves. Many RB barrels being made have grooves that are actually too deep. Grooves shallower than .008" can cause problems and grooves deeper than .012" can as well.

A soft slug with a long bearing surface can be shot in grooves as shallow as .002" either "naked" or paper patched. Those modern copper clad things in grooves even shallower, so shallow they are hard to see even. But hard bullets, cast or otherwise won't work well in a ML.

The cloth patch is the weak link. Cotton is weaker than linen, a lot weaker. If you have a .50 caliber rifle for example and its stripping cotton patches (ans a lot of the blue stripe ticking is now made "over there" by the commies and is too weak for out use here) try a tougher fabric like denim. Or find some linen. Linen is much tougher and will be harder to compress as well. So the same thickness will load harder. You may have to order test swatches from sellers on the WWW to find what you need look for a tight weave then wash hot and dry it to intentionally shrink the fabric. You may need a ball near bore size since linen is hard to find in the thickness of heavy cotton ticking or denim. If you are shooting a pure lead ball and the patch is "blowing" sometimes MORE powder will help since it will serve as an wad during initial acceleration. If not then up the patch thickness or ball size until the patch is imprinted on the ball by the lands and slightly by the grooves as well this will give a much better grip in the bore and support for the patch. The British used to use a thick felt wad under the ball. But it must be oversized to effect a seal since it must wrap around the ball. So the wad may need to be a 60 caliber for a 50 caliber rifle. Cushion shotgun wads may work since they are so thick. Sometimes just using one of the patches used to patch to ball over the powder will work.

If the ball/patch combo is hard to load use a slicker lube like tallow or Neatsfoot oil stiffened with some beeswax melted in. But often slick lubes do not provide the ultimate accuracy. But for hunting the accuracy should be all that will be needed. Shooting in paper target competition is another topic all together and generally requires different patch lubes and other changes. And FINALLY.

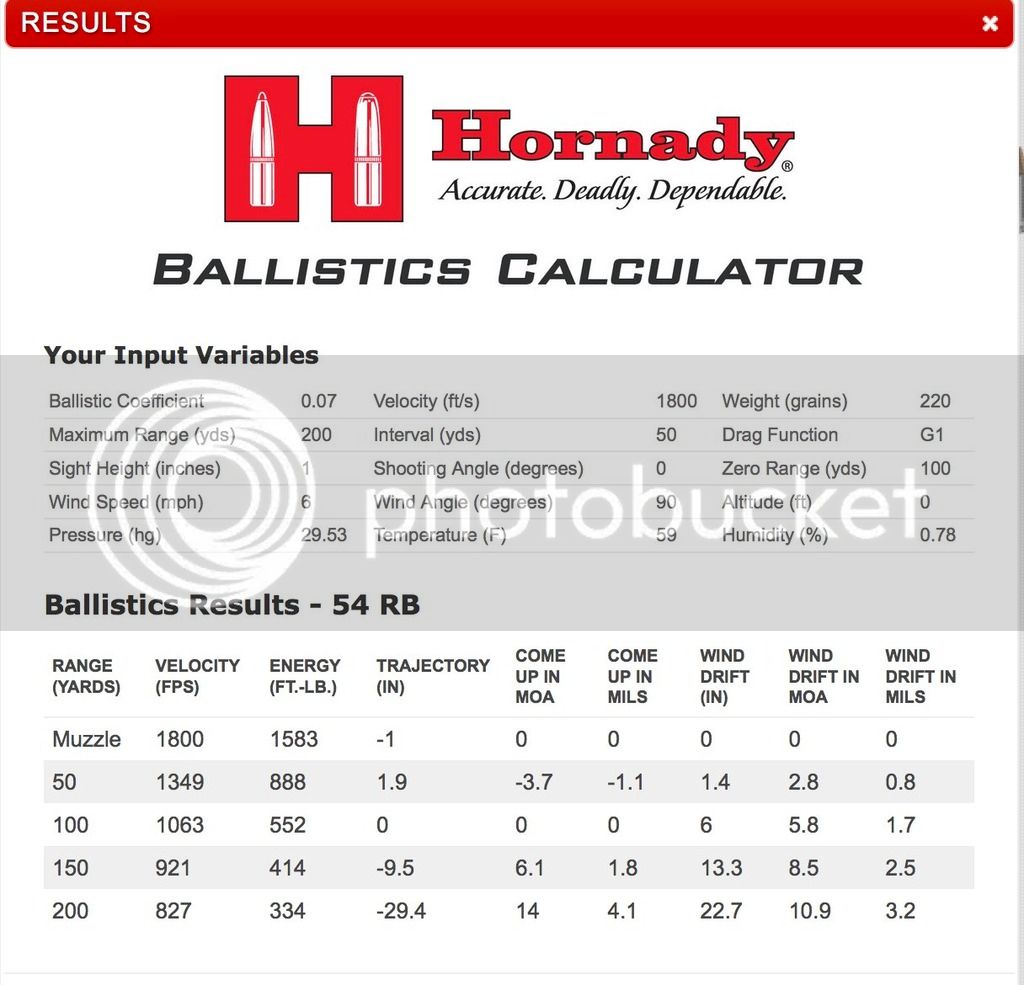

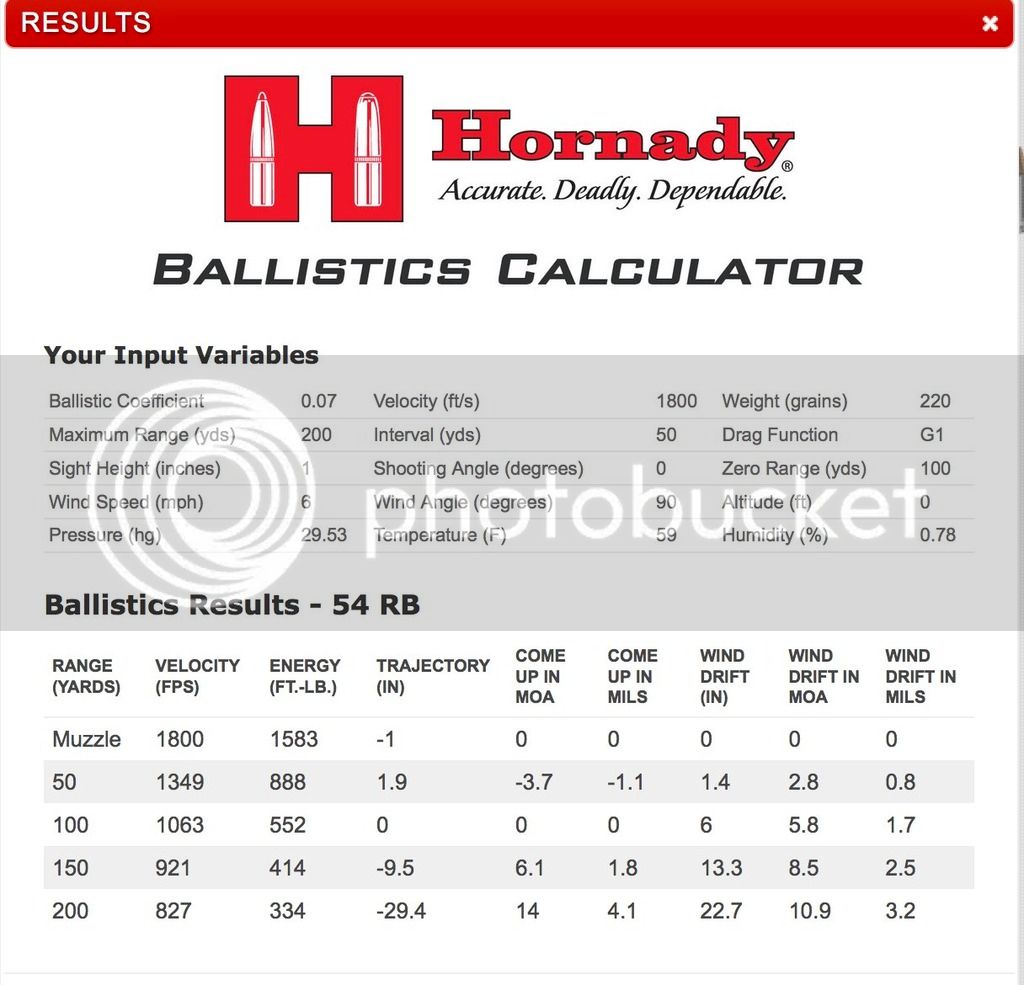

Even at 50 yards a slight breeze will move a RB an inch or more right or left and more wind can to some extent change elevation. See the chart for 6 mph wind below. At 100 its several times worse. So a rifle that will have all balls touching for 10 shots at 50-60 yards may shoot a 4" group in relatively mild breeze that comes and goes or varies in direction. I have shots go out 2" with some puff of wind that did not even show on wind flags. So one must CAREFULLY consider the conditions that you are shooting in when evaluating loads.

Dan

First. Define shallow grooves. Many RB barrels being made have grooves that are actually too deep. Grooves shallower than .008" can cause problems and grooves deeper than .012" can as well.

A soft slug with a long bearing surface can be shot in grooves as shallow as .002" either "naked" or paper patched. Those modern copper clad things in grooves even shallower, so shallow they are hard to see even. But hard bullets, cast or otherwise won't work well in a ML.

The cloth patch is the weak link. Cotton is weaker than linen, a lot weaker. If you have a .50 caliber rifle for example and its stripping cotton patches (ans a lot of the blue stripe ticking is now made "over there" by the commies and is too weak for out use here) try a tougher fabric like denim. Or find some linen. Linen is much tougher and will be harder to compress as well. So the same thickness will load harder. You may have to order test swatches from sellers on the WWW to find what you need look for a tight weave then wash hot and dry it to intentionally shrink the fabric. You may need a ball near bore size since linen is hard to find in the thickness of heavy cotton ticking or denim. If you are shooting a pure lead ball and the patch is "blowing" sometimes MORE powder will help since it will serve as an wad during initial acceleration. If not then up the patch thickness or ball size until the patch is imprinted on the ball by the lands and slightly by the grooves as well this will give a much better grip in the bore and support for the patch. The British used to use a thick felt wad under the ball. But it must be oversized to effect a seal since it must wrap around the ball. So the wad may need to be a 60 caliber for a 50 caliber rifle. Cushion shotgun wads may work since they are so thick. Sometimes just using one of the patches used to patch to ball over the powder will work.

If the ball/patch combo is hard to load use a slicker lube like tallow or Neatsfoot oil stiffened with some beeswax melted in. But often slick lubes do not provide the ultimate accuracy. But for hunting the accuracy should be all that will be needed. Shooting in paper target competition is another topic all together and generally requires different patch lubes and other changes. And FINALLY.

Even at 50 yards a slight breeze will move a RB an inch or more right or left and more wind can to some extent change elevation. See the chart for 6 mph wind below. At 100 its several times worse. So a rifle that will have all balls touching for 10 shots at 50-60 yards may shoot a 4" group in relatively mild breeze that comes and goes or varies in direction. I have shots go out 2" with some puff of wind that did not even show on wind flags. So one must CAREFULLY consider the conditions that you are shooting in when evaluating loads.

Dan

Dan that is a really good write up there and you made have to go back and reslug my barrel ,the land to land is .540 and groove to groove is .556 so the rifling depth is .008 on the money so I guess i really don't have shallow groove rifling after all.

As far as the pillow tick material i have some i have had for 15yrs or so i bought it in bulk and it is pretty good the new stuff i find is not.I do use drill cloth in this barrel an it works good approx. .021 in thickness and i have some Denim that is good too.

This barrrel is a little fickle in powder charge it will shoot 80 to 90 grains pretty accurate but not below or above this,but that is heavy enuff for my hunting,I have never shot anything beyond 110 yds.I have a 50cal with 1/66 twist and anythin form 60 up to 100grns it shoots good groups for me.

I also have a 58cal that is a tack driver but don't shoot it much anymore it has a Hoyt lined barrel.

Dan I also want to thank you again for the info on the Vent Liner you sent me,I know very little about Flint Locks . I have been working off and on for about 2 urs on a Verner 45 cal for my Son I am trying to get him back into Hunting at least shooting,right now my wife and 8 yr old Grand Daughter are my hunting pards.

Sorry for getting off subject here!

As far as the pillow tick material i have some i have had for 15yrs or so i bought it in bulk and it is pretty good the new stuff i find is not.I do use drill cloth in this barrel an it works good approx. .021 in thickness and i have some Denim that is good too.

This barrrel is a little fickle in powder charge it will shoot 80 to 90 grains pretty accurate but not below or above this,but that is heavy enuff for my hunting,I have never shot anything beyond 110 yds.I have a 50cal with 1/66 twist and anythin form 60 up to 100grns it shoots good groups for me.

I also have a 58cal that is a tack driver but don't shoot it much anymore it has a Hoyt lined barrel.

Dan I also want to thank you again for the info on the Vent Liner you sent me,I know very little about Flint Locks . I have been working off and on for about 2 urs on a Verner 45 cal for my Son I am trying to get him back into Hunting at least shooting,right now my wife and 8 yr old Grand Daughter are my hunting pards.

Sorry for getting off subject here!

Billnpatti

Cannon

- Joined

- Aug 11, 2008

- Messages

- 7,340

- Reaction score

- 44

Let me give a big :metoo: to the advice to get a copy of Dutch Schoultz' method and follow it carefully. The increase in accuracy can be amazing. :thumbsup:

I've been following this with a lot of interest, still working on the perfect load for my rifle. This may be obvious to the rest of you, but are you measuring compressed or non-compressed thickness in your discussions?shifty said:Right that shallow rifling don't hold that .490 RB real well with a .010 patch but up that patch thickness to .020 and it will do just fine and if your muzzle is crowned real good or has a good cone job it won't be much harder to load. I have a 54 cal shallow groove and was not able to get better than a 3" group at 50yds with 80grns FFg Daryl told me to try the thicker patch and now it will shoot 1 1/2" groups at 50 yds with 90grns powder and 100yds groups are as good as the 50yds used to be,and this is a 28" long barrel. :thumbsup:

Thanks,

Jamie

I know this is not the corrwect way to measure fabric but i use Dial Calipers and compress the frabric with my thumb and index finger on the artms of the caliper not with the wheel,I am not really interested in knowing what weight of fabric it is but in knowing what it will measure under compression so i can keep all the patch's as consistant as possible. If i don't put it under compression and just use slight pressure on the caliper i have no idea of how the fabric will compare with my other patch's, some thicker appearing fabric will actually measure thinner than some not so thick when under compression. Does this help you at all/ I know some on the site do not compress this much this is just how i do it.

Similar threads

- Replies

- 125

- Views

- 4K

- Replies

- 5

- Views

- 411

- Replies

- 37

- Views

- 2K