Doc Ivory

45 Cal.

Interesting and a lot of information.

-Doc

-Doc

Hi,

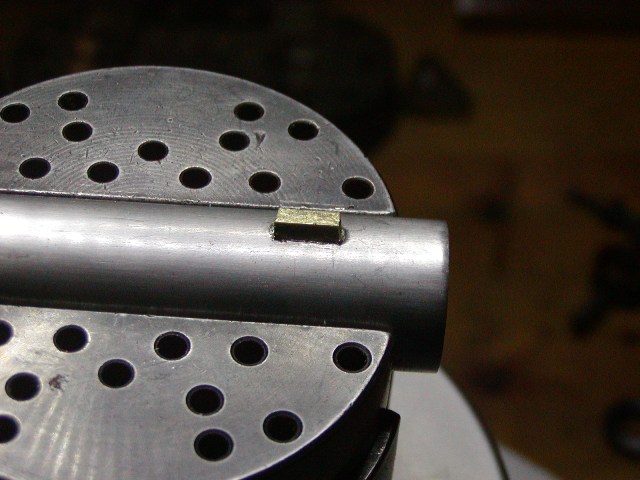

Thanks for looking folks. I thought some of you might want to see how I install a morticed front sight, which was a common way these sights were installed. Many horse pistols did not have any sights but many did and I wanted one. These were typically installed without any solder. The sight of gold, silver, brass, paktong, etc, was made with a tiny dove tail along the bottom edge. I cut a line with a jewelers saw and then file a dove tail on that line with a tiny triangular needle file.

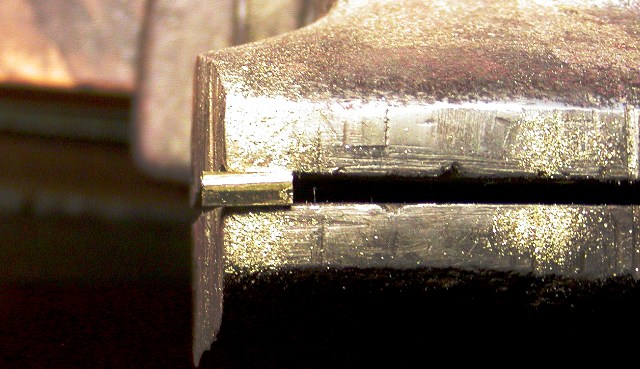

Then I engrave the outline of the mortice on the barrel. I find the center by placing the barrel upside down on a flat surface and keep it square to the surface. Then I slide a flat needle file under the barrel where the sight will go, and draw it out. It marks the center line perfectly. I outline the mortice with a square graver and then cut parallel lines within it to remover waste material.

Then I cut a smooth bottomed mortice with a 1/8" wide flat die sinker's chisel. When the mortice is at the right depth, I undercut the sides with a tiny flat on which the bottom flares out a little wider than the top. By cutting along the edges with that flat, it uncuts them.

Next, I place the sight in the mortice and tap it hard with a small ball peen hammer. That usually locks it in place so I can take a punch and peen the barrel around the sight. That peens metal into the dovetail on the sight and permanently locks it in place.

Finally, I clean up the barrel and sight and now have a neat and historically correct front sight.

dave

Remember Gus, the barrels were wrought iron not our modern steel, so cutting a mortice was not very hard. I have to work at it much harder than they did in the 18th century.

dave

Pretty much the way I tend to feel.I'll just go over and sit in the corner while a master craftsman does his work.

Thanks for sharing!

Same here!Pretty much the way I tend to feel.

I believe many a cold rainy evening could be endured reading posts like this and then dreams of similar resultsI just discovered this thread. Good reading ahead for tonight! Thanks @dave_person !

Indeed so!I believe many a cold rainy evening could be endured reading posts like this and then dreams of similar results

Enter your email address to join: