Garrett Wade. Lots of comments both good and bad. I think most of the problems are quality control. This dual axis vise is an awesome idea that should have been manufactured a little more. Im just going to say from the start that the vise I received was of decent quality for a made in China vise. I took it a step further and made this an awesome vise.

They give you a cheap drill bit and tap to add a metric screw with a plastic knob. The instructions are excellent and leave nothing to question. The only problem is the bit and tap are cheap and you have to go slow and use a lot of cutting oil, once done, i found the provided screw with knob sufficiently long for tapering.

I ground the screw to a point. I just guesstimated the angle.

I then placed the vise on the drum and leveled it for normal use. I put a little in-letting black on the point of the screw and screwed it in. I pulled the vise and drilled a dimple with a 3/16 bit. Just a dimple as you can see in the pics. I then put the vise back on the drum and rotated it up to its furthest position and marked that with the screw and black. I did the same same for the furthest position forward. I removed the vise and drilled those two points. Then drilled a series of dimples along the rotation line.

Now, even with the cheap knob, I can hand tighten the screw in a number of rotating positions and it locks in solid as a rock. I whacked the hell out of it with a ball peen and no movement what so ever.

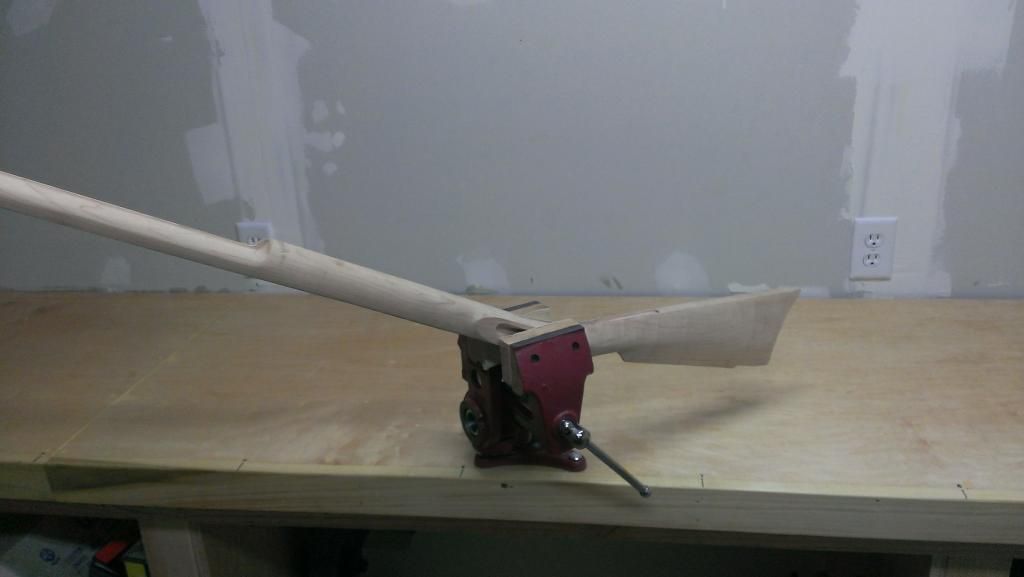

Here are some pictures of the different positions I drilled.

level

Now, I have heard people have had issues with the jaws not lining up. This vise has a screw with lock ring that is under the front jaw. This screw levels and locks rotation when the jaws are tightened. 30 seconds adjusting this screw and you have level jaws on closure.

Now is this vise worth the money, only you can be the judge of that. I was told these improvements are a significant cost increase during manufacturing and that is why they leave it up to you. You can do it if needed, or if you only do light work leave it as is. These mods were super easy, cup of coffee long to do. I am now extremely happy with it. It should serve me for a long time to come. Now to make jaw pads.

They give you a cheap drill bit and tap to add a metric screw with a plastic knob. The instructions are excellent and leave nothing to question. The only problem is the bit and tap are cheap and you have to go slow and use a lot of cutting oil, once done, i found the provided screw with knob sufficiently long for tapering.

I ground the screw to a point. I just guesstimated the angle.

I then placed the vise on the drum and leveled it for normal use. I put a little in-letting black on the point of the screw and screwed it in. I pulled the vise and drilled a dimple with a 3/16 bit. Just a dimple as you can see in the pics. I then put the vise back on the drum and rotated it up to its furthest position and marked that with the screw and black. I did the same same for the furthest position forward. I removed the vise and drilled those two points. Then drilled a series of dimples along the rotation line.

Now, even with the cheap knob, I can hand tighten the screw in a number of rotating positions and it locks in solid as a rock. I whacked the hell out of it with a ball peen and no movement what so ever.

Here are some pictures of the different positions I drilled.

level

Now, I have heard people have had issues with the jaws not lining up. This vise has a screw with lock ring that is under the front jaw. This screw levels and locks rotation when the jaws are tightened. 30 seconds adjusting this screw and you have level jaws on closure.

Now is this vise worth the money, only you can be the judge of that. I was told these improvements are a significant cost increase during manufacturing and that is why they leave it up to you. You can do it if needed, or if you only do light work leave it as is. These mods were super easy, cup of coffee long to do. I am now extremely happy with it. It should serve me for a long time to come. Now to make jaw pads.