- Joined

- Nov 26, 2005

- Messages

- 5,269

- Reaction score

- 11,146

Hi Lexington,

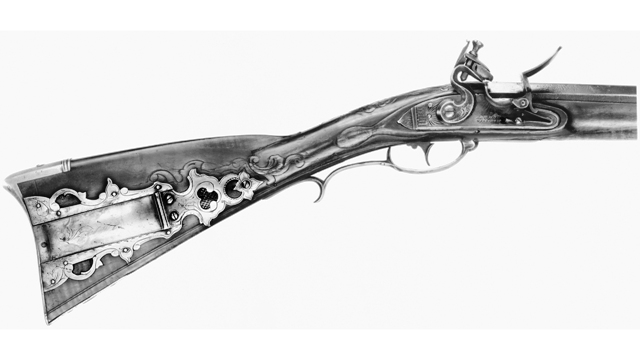

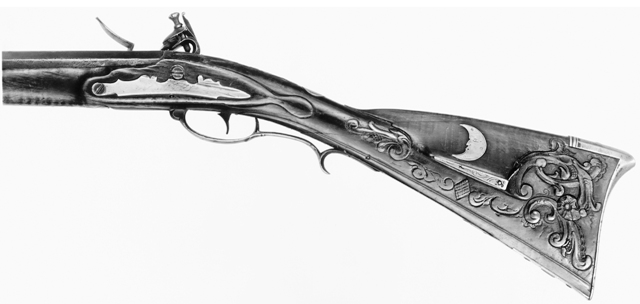

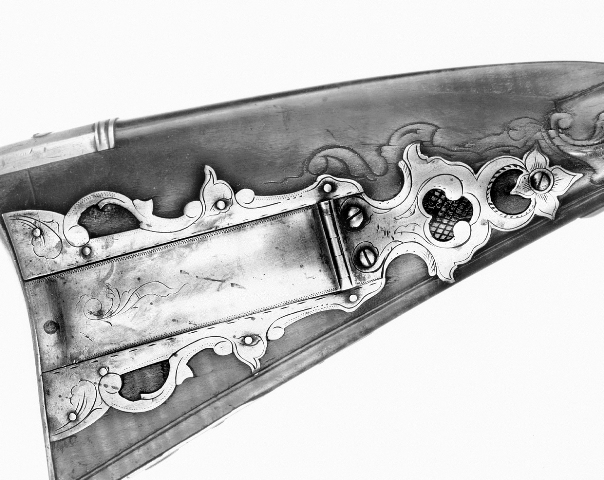

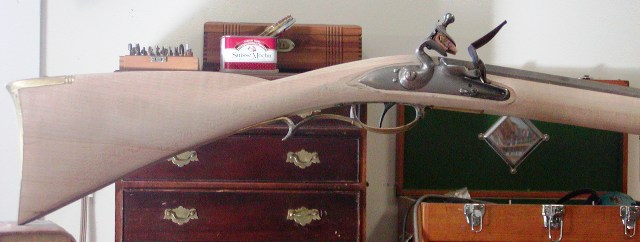

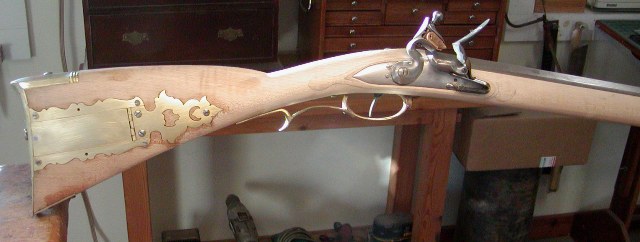

That looks like a nice later Berry. Folks debate if there was a father and son pair of Berrys or just the one maker who worked for a long time. Regardless, any Berry rifle is a great conversation piece.

dave

That looks like a nice later Berry. Folks debate if there was a father and son pair of Berrys or just the one maker who worked for a long time. Regardless, any Berry rifle is a great conversation piece.

dave