Hehe same here - non smoker!

A couple of words though, if you don't mind.

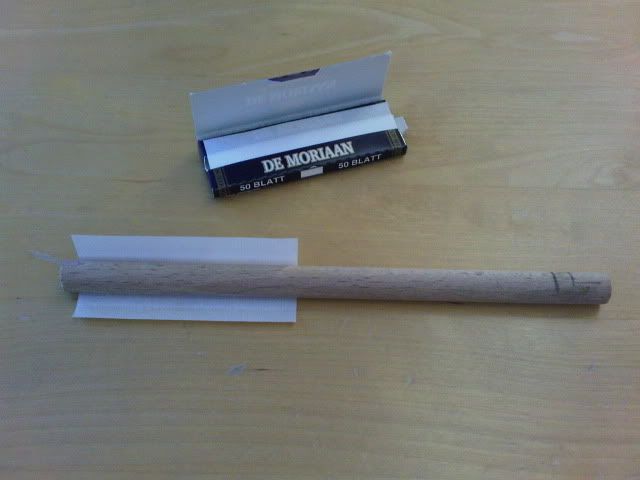

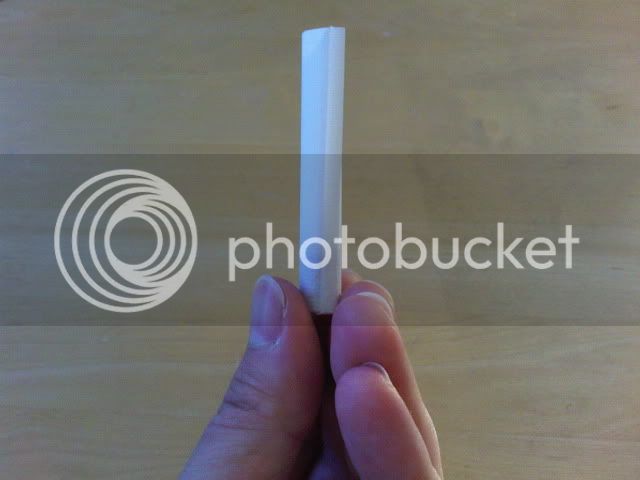

I roll the paper slightly to a cone shape because the dowel is 10mm (about 3/8") and only use the gumming in the lower section lets say about 1/4" this way the upper portion is left unglued to have some play to accept the bigger than 3/8" roundball. After a while you'll get the hang of it. Plus if the paper is long enough you get actually 2 cartridges out of one paper - no I'm not scottish :wink:

To close the bottom I only use hand pressure on the table top. If it's not holding tight for you, you can wet it a little bit - only a little bit the paper binds easily and it doesn't require a lot of moisture.

I selected the dowel by inserting it into the chamber. You want the dowel and subsequently the cartrigde the right width and length to stop with the bottom on the "rim" (lack of a better word) of the nipple. When you inspect the nipple there is a cone shape narrowing into the hole. The beginning of this cone you want the bottom to stop. when seating the ball/cartridge the pressure will open up the bottom and you'll have exposed powder.

So far I fired a couple of hundred of those cartridges and NEVER! had a misfire. As much a 15 reloads in a row. Some wiping down between the reloads is necessary, of course, and you probably want to put some grease over the ball and don't forget to lube the cylinder pin - this makes a world of difference.

Another thing I tried and use pretty frequently is making "pellets" instead of cartridges.

I only put powder and sometimes farina (depending on the load) in the paper hull and close it.That way you don't need a cone shape. You can roll the paper straight around the dowel. Loading just put a "pellet" in than put the ball on top and ram home - same principle applies as before. It is almost as quick for a reload. Similar to a field piece where you first insert the packaged propellant and then the projectile. That leaves room for playing with different RB diameters or if you are waiting for a delivery or didn't get around casting because of the weather you can still prepare the pellets without the RBs.

I frequently use the "pellet method" to be able to use lubed feltwads between powder and ball - that's even cleaner than over the ball grease.

Hope that helps,

Silex