FlinterNick

69 Cal.

- Joined

- Nov 1, 2018

- Messages

- 3,897

- Reaction score

- 2,929

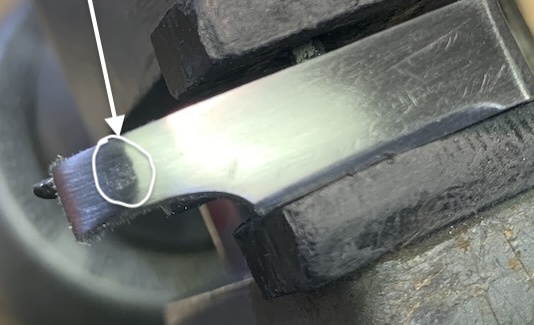

First nothing wrong with your lock from what I see. Just bad geometry. From observing you lock in action I would suggest a smaller flint or at least move the flint back a little so it is scraping the flint and not banging into it. Having the same musket for years I know they are very temperamental with flint size. Very easy thing to try with no possibility of messing anything up with your lock. Remember to KISS!.

The lock doesn’t have bad geometry, this Miroku Charleville lock is probably the best flintlock designs ever made on a Reproduction military musket.