I would appreciate anyone's opinion / knowledge / experience with this subject: Several years ago I acquired an original 1863 Springfield rifled musket in very good condition. Bore diameter is roughly .585. Research indicated the original charge was 50 grains, increased to 60 grains late in the Civil War due to concerns over powder "quality". One book contained many sketches of test firing results showing nice groups around the target center. Grain size was thought to be close to 2F, so I started using a .575 minie over 50 grains 2F, bench shooting at 100 yds. Surprisingly accurate considering it is 158 years old, shots with a clean barrel were high and to the left by a few minutes with a distinct group. Switching to .582 minies, same result except the groups were tighter. These rifles were subject to proof firing before Government acceptance, so it's hard to believe it would have left the factory shooting like that, so I switched to 40 grains of 3F which brought the groups down to the aiming point, still with a little left bias. This was a 20% reduction in powder weight, with a finer grain size. Still experimenting, but my present theory is that our powder is hotter than theirs was. What are your thoughts?

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Modern vs. Period Black Powder

- Thread starter Jkil

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It certainly wouldn't be surprising that bulk US government-issue black powder was of a generally inferior quality compared to that of the best rifle powders available at the time. I would frankly be surprised if that wasn't the case.

Col. Batguano

75 Cal.

- Joined

- Feb 10, 2011

- Messages

- 5,039

- Reaction score

- 1,423

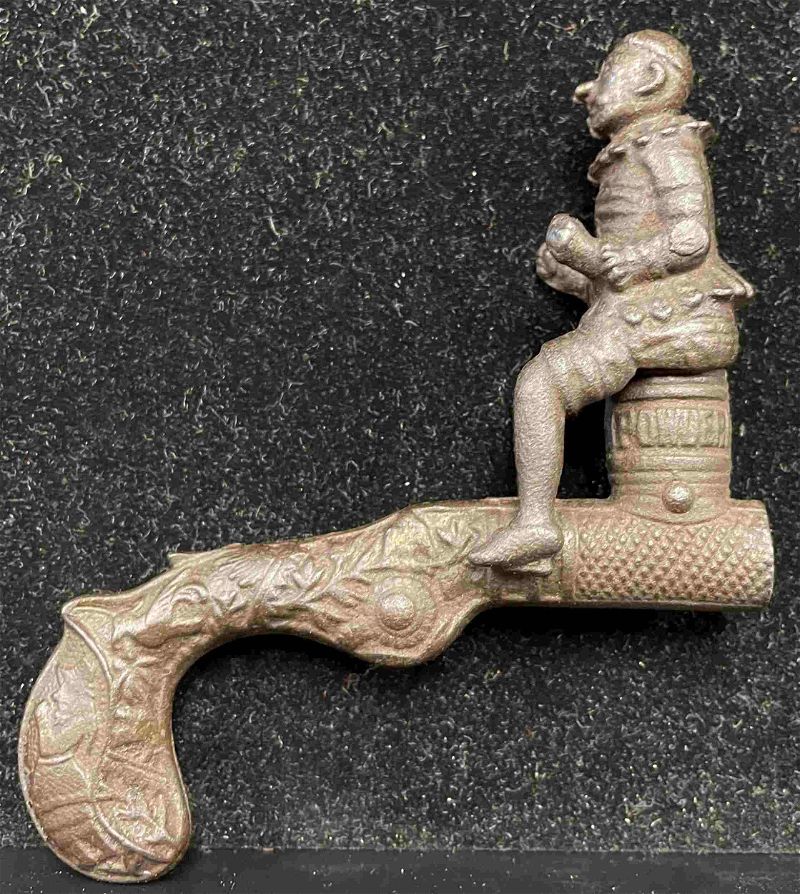

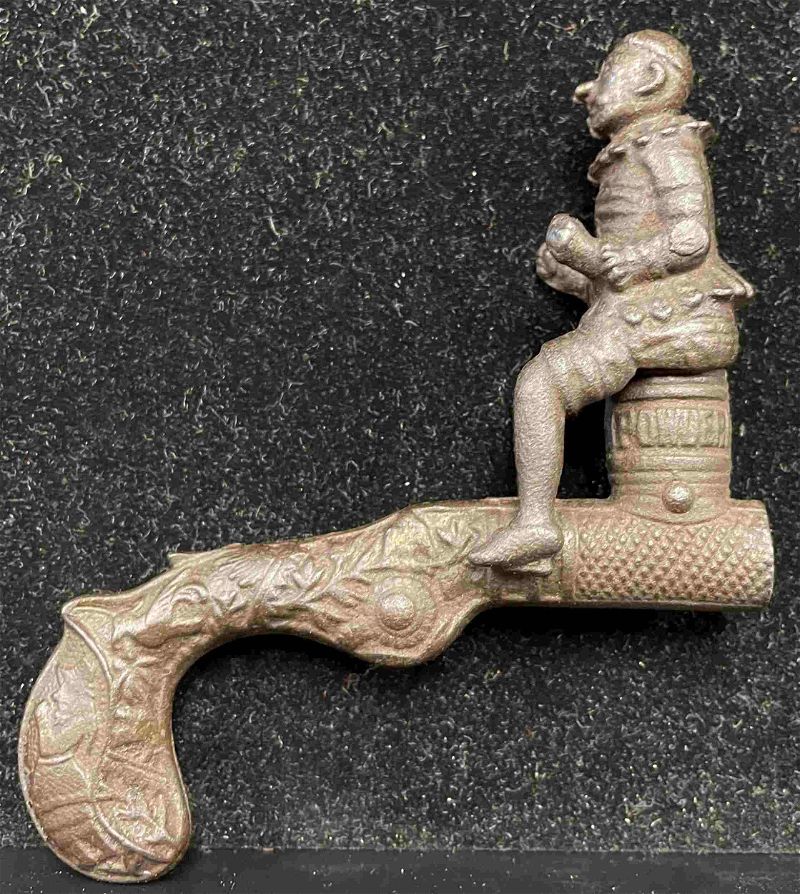

Powder from "back in the day" was of varying degrees of quality. They could certainly grind it (or actually screen it) to be of relatively uniform grain size, but it's the number of times they wetted it with the dextrin solution (and got the components to blend) that made the difference in burning rate. (If I go much further I will be violating the forum rule about making the stuff.) So, to allow for this, there were little pistol gizmos around that had a paddle that moved (it looks a little like a gunner's quadrant) when a small charge was lit. The further it moved, the more energetic the powder. It was scaled so that the shooter could adjust his load from the baseline. So (hypothetically), if the baseline charge moved the paddle to a 7, and the powder you just got moved it to a 6, you might put in 55 grains of powder to get the same velocity you got with a 50 grain load with the baseline powder.

If you do and advanced search here I bet you can find pictures of one. It's a fascinating device and one I'd like to have, particularly for teaching purposes.

If you do and advanced search here I bet you can find pictures of one. It's a fascinating device and one I'd like to have, particularly for teaching purposes.

They didn’t have chronographs then but did do ballistic pendulums. Also penetration test. Results from the eighteenth and nineteenth centuries are on par with today’s results.

In Morden test Swiss seems to outperform GO, and Elephant seems to be at the bottom if you have any.

I would think I wouldn’t want to try 60 grains of elephant in a gun that couldn’t handle 60 grains of Swiss

Should you have a cartridge full of ‘best’ powder with a 60 grain charge that had been kept in damp magazines and carried in rainy or foggy conditions then put to work, how would that compare to fresh ‘poor’or ‘common’ powder.

I would not doubt they got very different performance from shot to shot or company to company

In Morden test Swiss seems to outperform GO, and Elephant seems to be at the bottom if you have any.

I would think I wouldn’t want to try 60 grains of elephant in a gun that couldn’t handle 60 grains of Swiss

Should you have a cartridge full of ‘best’ powder with a 60 grain charge that had been kept in damp magazines and carried in rainy or foggy conditions then put to work, how would that compare to fresh ‘poor’or ‘common’ powder.

I would not doubt they got very different performance from shot to shot or company to company

- Joined

- Jan 9, 2008

- Messages

- 1,939

- Reaction score

- 2,187

With today's powder, the chemical components are much more pure than 200 years ago. It follows that today's powder will burn at a good rate compared to the old powder.

BTW, I found a good load for my three band Enfield was 44 grs FFFg and a 500 gr minie.These rifles were subject to proof firing before Government acceptance, so it's hard to believe it would have left the factory shooting like that, so I switched to 40 grains of 3F which brought the groups down to the aiming point, still with a little left bias. This was a 20% reduction in powder weight, with a finer grain size.

I thought "proofing" was to certify chamber pressure safety not barrel accuracy.

Canute Rex

40 Cal.

- Joined

- Apr 19, 2012

- Messages

- 397

- Reaction score

- 303

Powder from "back in the day" was of varying degrees of quality. They could certainly grind it (or actually screen it) to be of relatively uniform grain size, but it's the number of times they wetted it with the dextrin solution (and got the components to blend) that made the difference in burning rate. (If I go much further I will be violating the forum rule about making the stuff.) So, to allow for this, there were little pistol gizmos around that had a paddle that moved (it looks a little like a gunner's quadrant) when a small charge was lit. The further it moved, the more energetic the powder. It was scaled so that the shooter could adjust his load from the baseline. So (hypothetically), if the baseline charge moved the paddle to a 7, and the powder you just got moved it to a 6, you might put in 55 grains of powder to get the same velocity you got with a 50 grain load with the baseline powder.

If you do and advanced search here I bet you can find pictures of one. It's a fascinating device and one I'd like to have, particularly for teaching purposes.

The device was called an "eprouvette" Do a search for "eprouvette powder tester" and you'll get dozens of photos of little pistol handled thingees with serrated wheels on top.

Apparently some armories had a mortar at a fixed angle on a fixed base. They would load a weighed charge and a weighed ball and see how far it went.

With today's powder, the chemical components are much more pure than 200 years ago. It follows that today's powder will burn at a good rate compared to the old powder.

1863 isn't 200 years ago, black powder was practically a "mature technology" by then. They had excellent, top quality powder available at the time, but they simply weren't available in the staggering quantities needed for the Late Unpleasantness, and even if they were, government has always cheaped out. This was a problem all the way up - even in the 1960s.

Last edited by a moderator:

Melchi577

36 Cl.

powder testing mortar from a powder mill on Dartmoor the mill produced blasting powder for the mines so probably a bit too slow burning for an eprouvette to work well.

making powder needs very careful preparation of the charcoal as well as high purity of the other ingredients. the sort of things that get difficult with an active war going on.

Britain being at war with somebody nearly all of the time and far from its shores in the 19thC was able to maintain a large production and excellent quality. but we got bored with all that and now import all of ours.

Was Elephant made in Brazil, is it today Diamondback? I think our powders today are

better than ever. The equipment is safer and better. The costs are way up. The first

can I got in 1967 was under 3 bucks and from dynamit nobel which was high. I still

have the can somewhere in my garage. Caps are way better today and fire near every

time. There has never been a better time to be into the old time shooting and

hunting fun.

better than ever. The equipment is safer and better. The costs are way up. The first

can I got in 1967 was under 3 bucks and from dynamit nobel which was high. I still

have the can somewhere in my garage. Caps are way better today and fire near every

time. There has never been a better time to be into the old time shooting and

hunting fun.

Last edited:

Col. Batguano

75 Cal.

- Joined

- Feb 10, 2011

- Messages

- 5,039

- Reaction score

- 1,423

Here's an interesting variation of an eprouvette, though obviously done as a gimmick, not as a legitimate testing piece.

Was Elephant made in Brazil, is it today Diamondback? I think our powders today are

better than ever. The equipment is safer and better. The costs are way up. The first

can I got in 1967 was under 3 bucks and from dynamit nobel which was high. I still

have the can somewhere in my garage. Caps are way better today and fire near every

time. There has never been a better time to be into the old time shooting and

hunting fun.

Elephant BP was made in Brazil, but it is not Diamondback. The latter is made in the same facility, but is much cleaner and faster burning than Elephant. I used at least a case of it recently and wish I could get it again.

Archer 756

40 Cal.

We must also remember that back years graphite was not part of powder what effect does it have on powder ?

Graphite keeps the powder corns loose and reduces caking giving a consistent

burn. Also reduces static sparks and untoward ignition.

First introduced by swiss powder works.

burn. Also reduces static sparks and untoward ignition.

First introduced by swiss powder works.

Glossing the powder corns with graphite goes way back, it isn't some new-fangled process. Well before the Civil War anyway.

One other attribute in addition to those mentioned is it helps prevent moisture absorption.

It's why the "g" is listed after the powder granulations - FFFg for example.

One other attribute in addition to those mentioned is it helps prevent moisture absorption.

It's why the "g" is listed after the powder granulations - FFFg for example.

Here's a photo of a powder tester from around 1730. It's unusual for being good-looking (there's a pointer and a scale on the other side of the wheel); most were ungainly, cobbled-together affairs. If you're interested, there's a good book: "Eprouvettes", by TRW Kempers.

- Bill

- Bill

JCKelly

45 Cal.

Ord Sgt - "With today's powder, the chemical components are much more pure than 200 years ago"

Old powder used reasonably pure POTASSIUM nitrate, which burned red. Remember "the rockets' red glare" ?

DuPont's mill in Eastern Pennsylvania burned orange or yellow, either because they used their old blasting powder mix or who knows.

Ask Mad Monk

Best powder today is Swiss.

Best during Civil War was Confederate, made in Georgia. The Union destroyed this mill at request of du Pont, who really did not want the competition after the war . . .Nothing, nothing has changed now, has it?

Old powder used reasonably pure POTASSIUM nitrate, which burned red. Remember "the rockets' red glare" ?

DuPont's mill in Eastern Pennsylvania burned orange or yellow, either because they used their old blasting powder mix or who knows.

Ask Mad Monk

Best powder today is Swiss.

Best during Civil War was Confederate, made in Georgia. The Union destroyed this mill at request of du Pont, who really did not want the competition after the war . . .Nothing, nothing has changed now, has it?

Buck Conner

40 Cal

Graphite keeps the powder corns loose and reduces caking giving a consistent

burn. Also reduces static sparks and untoward ignition.

First introduced by swiss powder works.

William your posts on this subject are "right on", nice work bud .....

hanshi

Cannon

Powders of old ranged from poor to absolutely excellent depending on era, national situation, uses and other criteria. Wartime meant powder needed in vast quantities and needed fast! Quality, of course, suffered as a result. Some old BP cartridges - just for comparison - still give velocities superior to those loaded with many modern black powders. Rifles usually required a better powder than smoothbores or rifled muskets (1863 for example) for the hunter and target shooter. Quality in the old days, even moreso than today, was all over the map.

- Joined

- Jul 31, 2006

- Messages

- 3,936

- Reaction score

- 1,043

DuPont became a dominant force in the black powder market because they made better quality powder than most of their competition. Their quality was based on testing each component and each step in the process as well as the finished product. A visit to the Hagley Mill site in Delaware is well worth the time.

Similar threads

- Replies

- 125

- Views

- 4K

- Replies

- 10

- Views

- 976

- Replies

- 18

- Views

- 3K