-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Morse "inside lock" musket

- Thread starter runes

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I found this on the Morse carbine...

Anthony and Hills Pictorial History Confederate Longarms and Pistols said:Morse

"The Patent model cased sets were manufactured by the Muzzy & Co. in Worchester, NY for George Woodward Morse, an inventor who used these sets to promote his new breech-loading arm. Even though this Morse Combination Rifle-Shotgun is not a Confederate Firearm, it was included in this book to tell the whole Morse story. Morse held many U.S. patents on firearms. In 1861, Morse tried to sell 6000 breech-loading carbines to Texas. These carbines were to be manufactured in Europe; however, the contract was never concluded. At the start of the war, Morse became the first superintendent of the Nashville Armory in Nashville, Tennessee. Here he began to tool-up to manufacture his new design carbine. He chose brass for the receiver because this non-ferrous metal could be casted and machined easier with semi-skilled labor. He started making parts in Nashville in until February 1862 when the city fell. His operation was transferred to Atlanta, Ga. where he worked with H. Marshall & Co., a sword manufacture. In an article in the Atlanta Daily Intelligencer, dated December 13,1862, Mr. Marshall presented and demonstrated the new Morse Carbine to the public. The article gave a complete description of the carbine and its new cartridge.

The Atlanta production carbine was assembled from parts from the Nashville Armory and the H. Marshall & Co. The number of carbines produced in Atlanta is believed to be between 200 and 400. The highest serial number known for an Atlanta Carbine is serial #180. This carbine is identical to the Atlanta prototype carbine except for its brass floor-plate and serial number. Both carbines are .54 caliber and their measurements are the same. It appears that the large serial number carbines were from Atlanta production and the small serial number carbines were from the Greenville production. The lowest serial number carbine observed is #425. The serial range for the Atlanta production was between one and 200 to 400 and the Greenville production between 300 to 1025. The operating lever on the Atlanta carbine was one-piece brass and quite heavy. The bolt head which contained the firing pin was also one-piece brass. The action was only locked when the hammer was down in the fired position.

Upon close examination after testing, it was found that improvements were necessary because the bolt face became eroded by the escaping gas from punctured caps. Also the brass bolt face had begun to set back. Another fault which had to be solved was a latch for the operating lever. When the gun was cocked and held up at a 45 degree or more angle, the breech would open and extract the chambered shell. Some of the early production carbines were recalled to the factory to have latches applied....

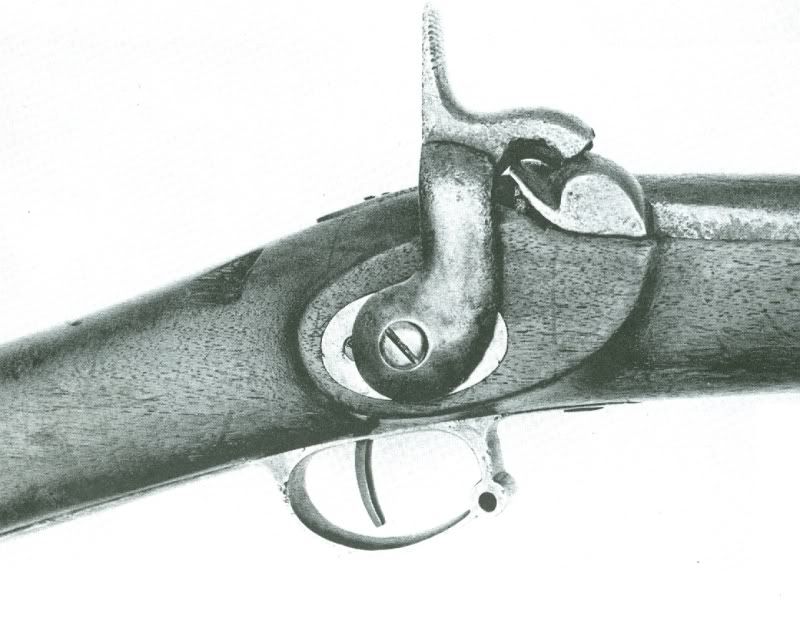

Morse inside lock musket.

Don't understand moving my post. The morse musket is by all definitions a muzzle loading smooth bore musket. Yes there is a morse carbine but that is not what I asked about. The morse has a small oval lockplate but otherwise appears to be a normal issue musket of the period.

Don't understand moving my post. The morse musket is by all definitions a muzzle loading smooth bore musket. Yes there is a morse carbine but that is not what I asked about. The morse has a small oval lockplate but otherwise appears to be a normal issue musket of the period.

oliver said:The morse musket is by all definitions a muzzle loading smooth bore musket.

Can you provide a photo of one?

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

Here are two views of a Morse Inside Lock carbine. The musket was made the same.

The flintlock shown above is not one.

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

I think I've seen a drawing somewhere of the workings, but can't remember where. I've been looking in my books but so far nothing has turned up. I'm assuming (and you know how dangerous that is) that it's made up of a tumbler and sear with the mainspring probably attached to the trigger plate or trigger guard plate. The sear spring could be hung on the small lock plate or maybe even the trigger plate. But, without pictures or drawings this is just a guess.

From what I've read, only about 140 of both the musket and carbine were made.

From what I've read, only about 140 of both the musket and carbine were made.

Russ T Frizzen

70 Cal.

- Joined

- Nov 9, 2004

- Messages

- 5,007

- Reaction score

- 423

It may have been the answer to a question no one was asking. There was a lot of that going on in this time period.

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

From what I can see, Morse's idea of a lock of this design was to save on materials wherever possible, in this case iron. But this design would also mean a different setup for the stock turning machine and inletting machine. The mainspring would also have to be a different design from the standard as well. So there's the problem of supplying spare parts for the field armorers as well.

The Richmond rifle-musket's lock was reduced in size presumably to save on iron as well. The high hump of the '55 was not needed (for the Maynard system) and part of it was cut off. It still had a high profile compared to the US '61 model. This profile didn't require the lock mortise to be changed as it would have to be to use the lock common to the '61 Springfield. The Fayetteville Rifle is a different story. After the humpback plates on hand were used up, they re-shaped the mortise and used a standard plate as well as changing the hammer, making it a distinctive model.

Morse was a brilliant designer, but the inside lock was not his brightest idea.

The Richmond rifle-musket's lock was reduced in size presumably to save on iron as well. The high hump of the '55 was not needed (for the Maynard system) and part of it was cut off. It still had a high profile compared to the US '61 model. This profile didn't require the lock mortise to be changed as it would have to be to use the lock common to the '61 Springfield. The Fayetteville Rifle is a different story. After the humpback plates on hand were used up, they re-shaped the mortise and used a standard plate as well as changing the hammer, making it a distinctive model.

Morse was a brilliant designer, but the inside lock was not his brightest idea.

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

hawk 2 said:what of the scare on the wood of the stock ?

would that be from the hammer?

that would be alot of hammer travel is so.

Something probably dinged it sometime. It is possible that it was shot with a burnt out nipple and a heavy load and the hammer was blown back. I had that happen with a Whitworth once. That mark is pretty much in line with the arc of the hammer. Then the wood would have been weakened there and later on somebody picked at it or something and a piece came off. But I'd say it was likely hit by something. Who knows? :hmm:

GreenMtnHunter

Pilgrim

oliver said:Thank you Kanawha ranger

Thats it. I wanted to reproduce the lock for myself, but can't seem to find drawings or photo of insides.

Thank you both! Great thread! I had no idea...!

Rich

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

You're welcome! There's a lot of neat old guns out there! :grin:

Hi gang, thanks for the interest in the Morse lock. I have spent days now trying to track down a picture of the workings. Once I get a bug like this It's hard to give up. This must be a really simple lock to take up so little space.

Similar threads

- Replies

- 28

- Views

- 1K

- Replies

- 4

- Views

- 290