splinter84

36 Cal.

- Joined

- Jan 4, 2013

- Messages

- 66

- Reaction score

- 0

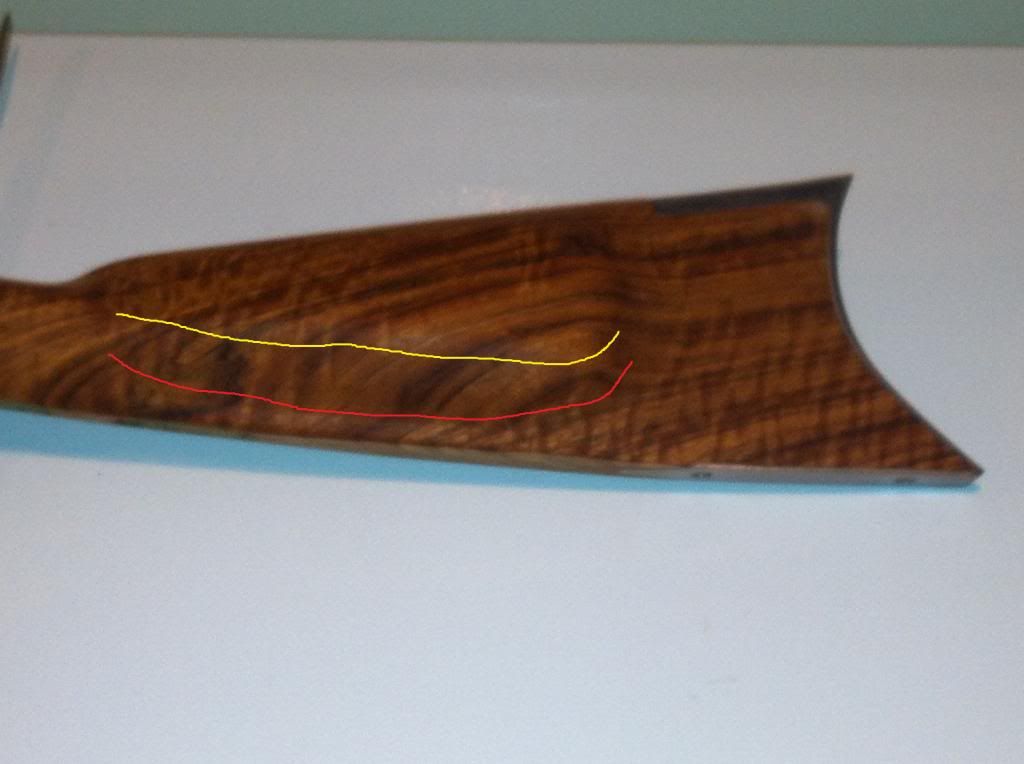

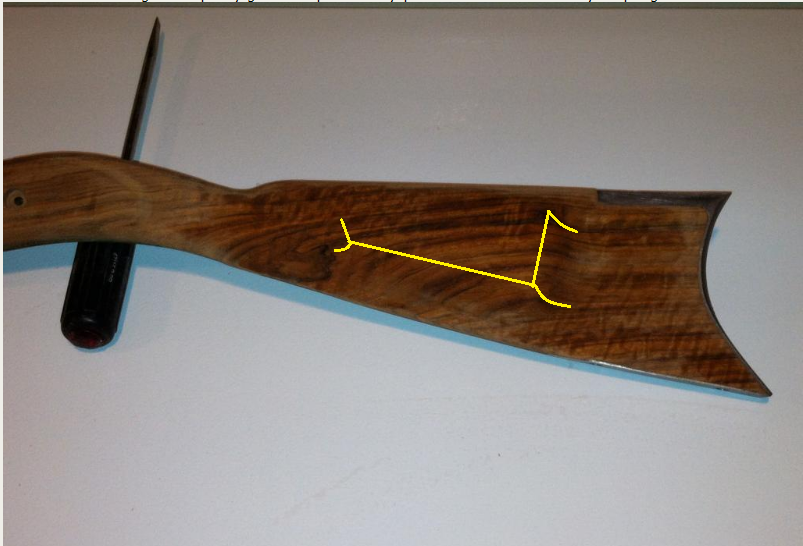

I’m posting another update on my GPR build. I have been working on the buttstock for the most part, and I think I am getting it very close to my final shape. I have some light shaping and final sanding with the 50 grit before I call it good and move further up the stock. My goal on the buttstock was to remove some of the material on the toe and slim the “monte carlo” down some. It seemed bulky out of the box. I am not sure if my lines are “authentic” but that’s OK. I just want a good feel and pleasant look. I haven’t put any time into the grip yet.

The lipstick tip worked well for the buttplate. I can barely slip a piece of typing paper in the seam between the stock and plate. Not sure if I can get it any better than that, but maybe a couple of nights of fine tuning and I will have it. I do have some more work to do on top of the buttstock to meet it up with the butt plate a little better as well.

PS. It looks like I am going to have a long wait to get my replacement tang back from Lyman. I guess they are swamped with orders. I mentioned in my first thread that my tang had a gummed up flat on one side so I sent it back for replacement.

I wanted to share some progress pics to see what you guys think and if I should make any changes or improvements on the shape of the buttstock. I wetted it down a little bit last night to hopefully get better pictures. My iphone camera is a little blurry. I apologize for that.

The lipstick tip worked well for the buttplate. I can barely slip a piece of typing paper in the seam between the stock and plate. Not sure if I can get it any better than that, but maybe a couple of nights of fine tuning and I will have it. I do have some more work to do on top of the buttstock to meet it up with the butt plate a little better as well.

PS. It looks like I am going to have a long wait to get my replacement tang back from Lyman. I guess they are swamped with orders. I mentioned in my first thread that my tang had a gummed up flat on one side so I sent it back for replacement.

I wanted to share some progress pics to see what you guys think and if I should make any changes or improvements on the shape of the buttstock. I wetted it down a little bit last night to hopefully get better pictures. My iphone camera is a little blurry. I apologize for that.