Ok, I've spent hours reading this forum and searching the net for similar forums and I have to say this one is the one that has caught my eye and retained my attention the best. Thanks for being here guys.

I'm going to be a pest, no pretending not to be, let's be honest ok? LOL.

I have lots of questions and I'm not afraid of taking criticism and advice. I'm' not shy and have a really THICK hide so you don't have to worry about hurting my wittle feewings ok? :wink:

I've built one drop in kit a couple of decades ago and now I'm going to build a parts kit I picked out from Muzzleloader Builder's Supply

http://www.muzzleloaderbuilderssupply.com/index.html

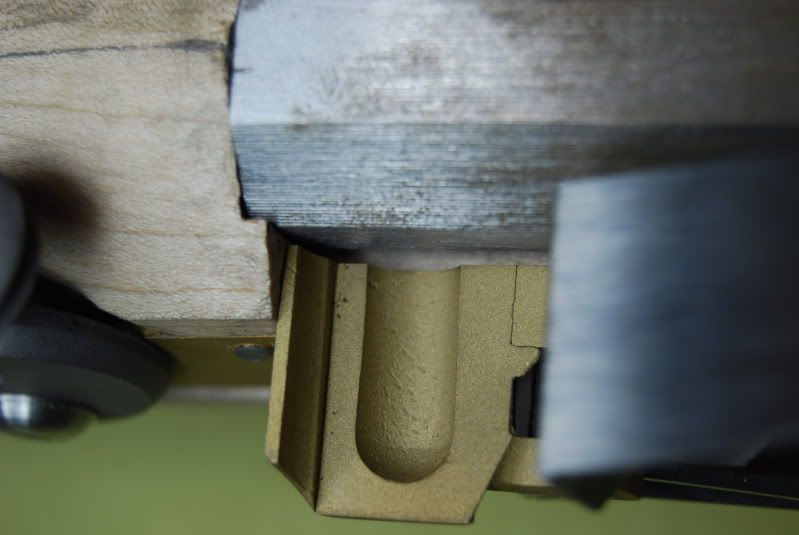

I had the Colerain Swamped 50 cal barrel inlet for me as well as the siler flintlock and trigger.

There is a lot of wood left on the precarved piece of high grade (not top grade $$) curly maple and I have plenty of hardware to install. The owner (Ryan I believe) helped me pick out the hardware (furniture?) to make this period correct and uniquely mine. I'm excited.

After reading a little bit here, I went back to the computer and pulled out the credit card and ordered a few more books! I don't have the titles at hand but picked up some nice ones on building techniques and carving patterns and engraving patterns and a very good looking book on learning to engrave (I'll me a long time practicing with that book long after this rifle is built I'm sure!).

So, I would appreciate any comments, assistance, critiques and so on as I go. I'll try to keep my progress well documented.

My first question today is about tools.

It's obvious to me now I am woefully under-tooled.

Since inletting my breech plug is first on my task list I'll be using my hand carving chisels which I'm confident I have enough of, but files are lacking.

What are your suggestions for rasps and files? Both for wood and metal of course.

I'm going to be a pest, no pretending not to be, let's be honest ok? LOL.

I have lots of questions and I'm not afraid of taking criticism and advice. I'm' not shy and have a really THICK hide so you don't have to worry about hurting my wittle feewings ok? :wink:

I've built one drop in kit a couple of decades ago and now I'm going to build a parts kit I picked out from Muzzleloader Builder's Supply

http://www.muzzleloaderbuilderssupply.com/index.html

I had the Colerain Swamped 50 cal barrel inlet for me as well as the siler flintlock and trigger.

There is a lot of wood left on the precarved piece of high grade (not top grade $$) curly maple and I have plenty of hardware to install. The owner (Ryan I believe) helped me pick out the hardware (furniture?) to make this period correct and uniquely mine. I'm excited.

After reading a little bit here, I went back to the computer and pulled out the credit card and ordered a few more books! I don't have the titles at hand but picked up some nice ones on building techniques and carving patterns and engraving patterns and a very good looking book on learning to engrave (I'll me a long time practicing with that book long after this rifle is built I'm sure!).

So, I would appreciate any comments, assistance, critiques and so on as I go. I'll try to keep my progress well documented.

My first question today is about tools.

It's obvious to me now I am woefully under-tooled.

Since inletting my breech plug is first on my task list I'll be using my hand carving chisels which I'm confident I have enough of, but files are lacking.

What are your suggestions for rasps and files? Both for wood and metal of course.

Last edited by a moderator: