Ok, what we gotta do is get some terminology and trigger function understanding going on.

your TC Double Set Double Throw trigger has two triggers right,,(?)

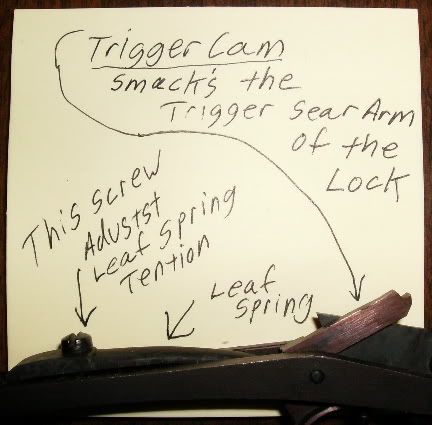

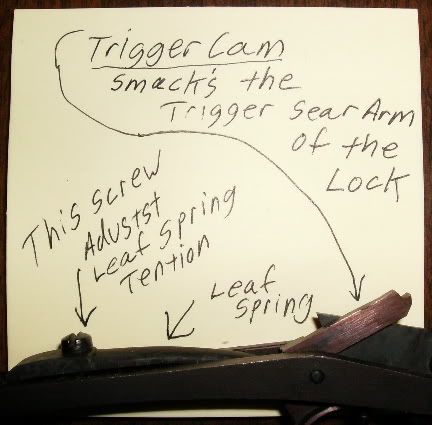

Each trigger has a "cam" that will push against the locks "sear arm" to disengage the sear from the "tumbler".

The rear trigger cam is supposed to only work when the rear trigger has been pulled back and it's cam "set" into a notch in the front trigger.

Your right,, when "set" the rear cam is fully down and won't interfere with the sear arm.

Two things can happen that will result in the rear cam interfering like you have going on.

1. The trigger plate itself can be too deep in the stock,, this is common with many older CVA/Traditions rifles,, the wood get's dry and people over tighten the screws compressing it and sooner than latter the triggers just get too deep, The fix for this is to shim or bed the trigger inlet to get the trigger plate back in proper position.

2. Usually with the TC triggers the rear leaf spring is pressing too hard on the rear trigger forcing the rear cam too high,, all that needs to be done is to adjust the screw for the leaf spring to bring it down. With the lock out you can look at the cams through the hole in the lock mortise and see where the cams position are in relation to where the sear arm will go.

your TC Double Set Double Throw trigger has two triggers right,,(?)

Each trigger has a "cam" that will push against the locks "sear arm" to disengage the sear from the "tumbler".

The rear trigger cam is supposed to only work when the rear trigger has been pulled back and it's cam "set" into a notch in the front trigger.

Your right,, when "set" the rear cam is fully down and won't interfere with the sear arm.

Two things can happen that will result in the rear cam interfering like you have going on.

1. The trigger plate itself can be too deep in the stock,, this is common with many older CVA/Traditions rifles,, the wood get's dry and people over tighten the screws compressing it and sooner than latter the triggers just get too deep, The fix for this is to shim or bed the trigger inlet to get the trigger plate back in proper position.

2. Usually with the TC triggers the rear leaf spring is pressing too hard on the rear trigger forcing the rear cam too high,, all that needs to be done is to adjust the screw for the leaf spring to bring it down. With the lock out you can look at the cams through the hole in the lock mortise and see where the cams position are in relation to where the sear arm will go.