- Joined

- Jan 23, 2021

- Messages

- 186

- Reaction score

- 142

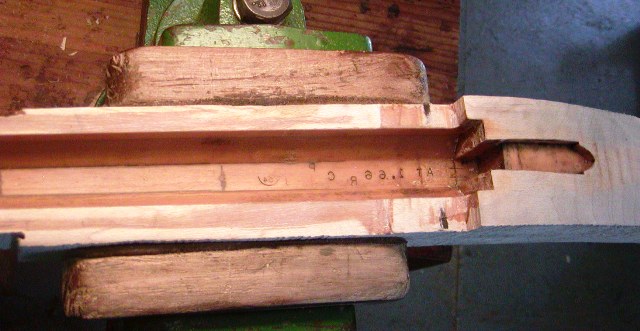

Did a search… couldn’t find an answer. New build. Plain maple stock.

When would be the better time to add Acraglas to the barrel channel. In the “white” or after the rifle is color stained. Planning on a very dark stain. Trying to avoid a potential problem, not sure. Will the release agent mess up the stain? Pretty tight fit, gonna be some squeeze out.

Thanks, Mule333

When would be the better time to add Acraglas to the barrel channel. In the “white” or after the rifle is color stained. Planning on a very dark stain. Trying to avoid a potential problem, not sure. Will the release agent mess up the stain? Pretty tight fit, gonna be some squeeze out.

Thanks, Mule333