plmeek

40 Cal.

As a general rule, you do not want any "powder chamber" to be any larger than the land-to-land ID.

Why would this be so? I would think a no shoulder transition from chamber to rifled bore would be the best option available.

Short answer: Murphy's Law, "Anything that can go wrong will go wrong, and at the most inopportune time."

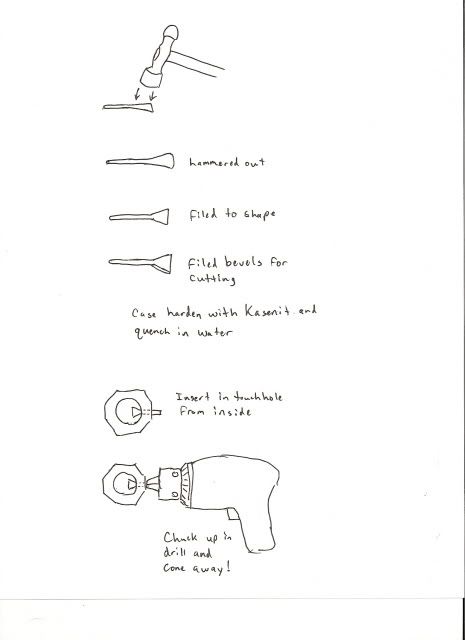

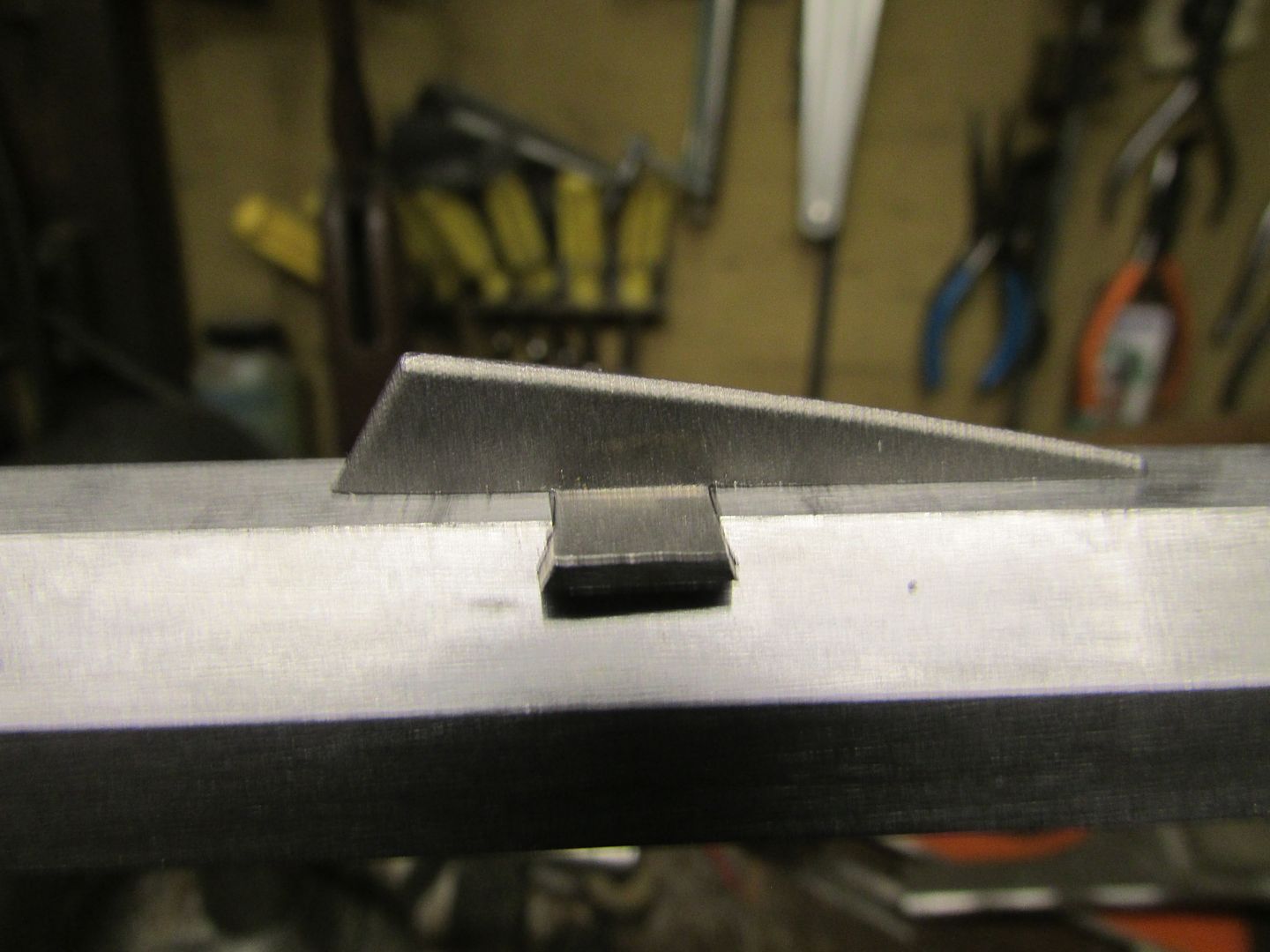

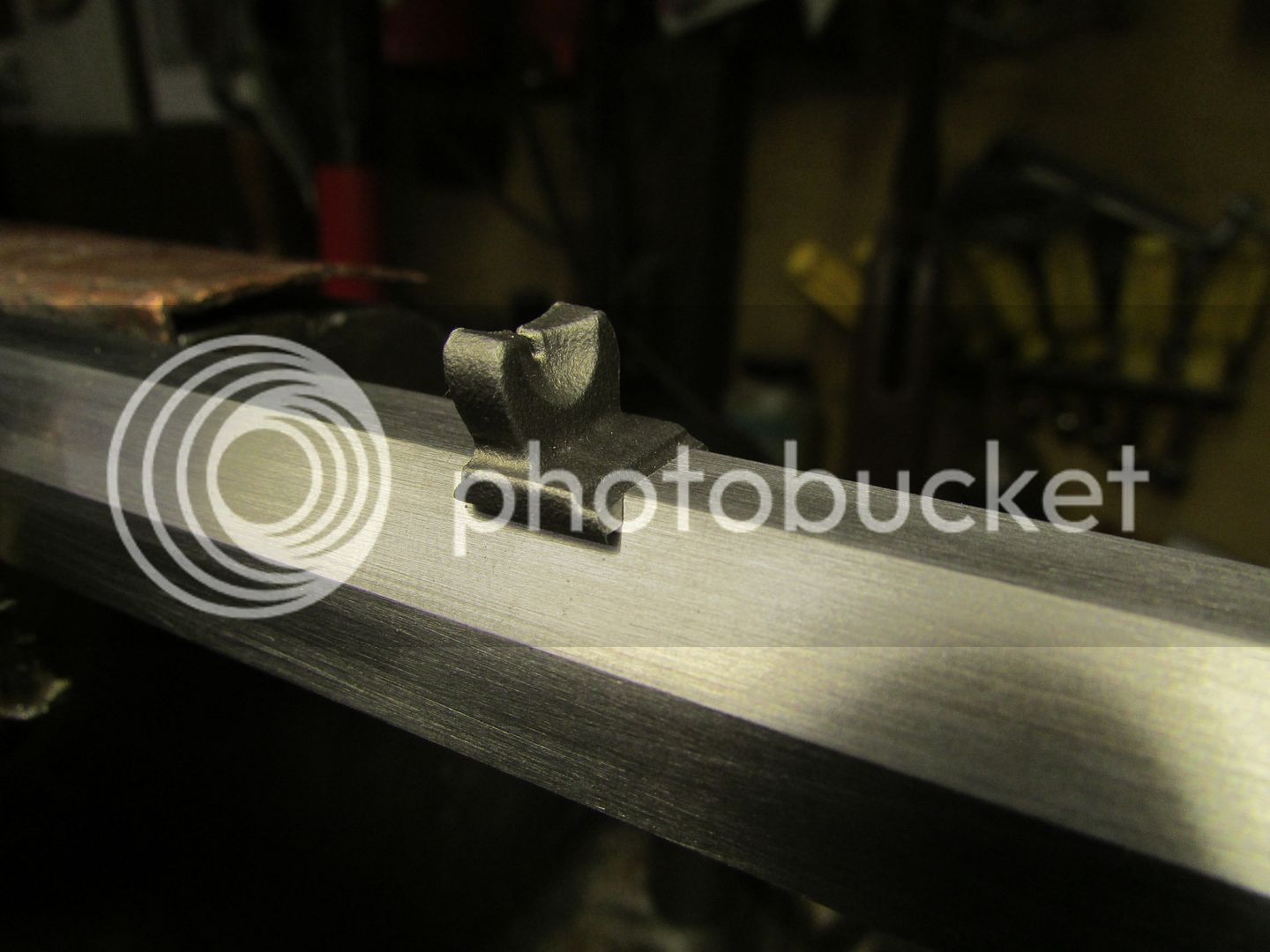

Long answer: You don't have to have a shoulder to hang up the patch and jag. The typical cleaning jag, as illustrated below, is designed to allow the patch to "bunch up" in the grooves of the jag when starting to pull it out of the bore.

This action helps to push some of the patch into the grooves of the bore and aid in the cleaning process. You can sometimes feel this as more resistance when pulling the rod and jag out of the bore during cleaning. The extreme example is when one pushes a dry patch down a fouled bore and tries to extract it. There is usually no problem when going down the bore with the dry patch. But when one tries to pull the rod back out, the dry, hard fouling provides maximum friction, forcing the patch to "bunch up" in the grooves of the jag. The result is often a stuck jag and rod.

Tapering the transition from no lands to full lands over a short distance may minimize the risk, but according to Murphy's Law, won't eliminate it. If enough fouling or patch material gathered around the jag in the enlarged section in just the right way, it might not compress enough in the taper section to fit the land-to-land ID and wedge itself there.

Your idea of "a longer jag of brass that keeps part of the patch in the rifling ahead of the groove diameter chamber" might work. I don't know. Might be something to experiment with on a waist section of barrel before you make an irreversible modification to your good barrel.

Phil