- Joined

- Nov 1, 2018

- Messages

- 3,884

- Reaction score

- 2,914

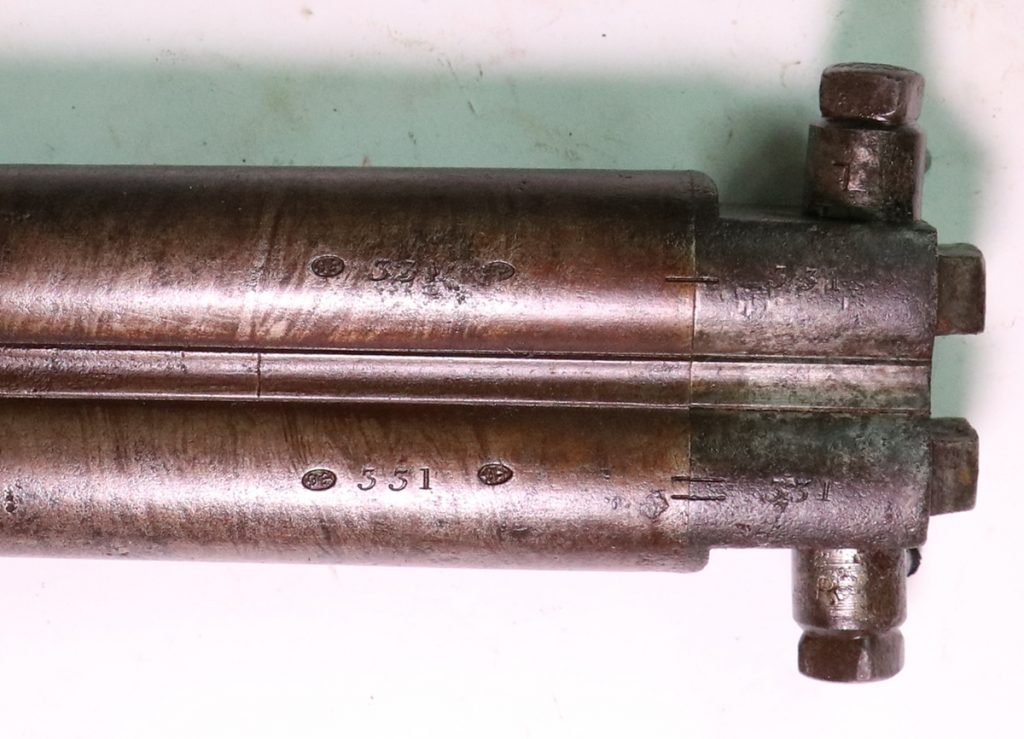

Many of the original barrels I've unbreached were notched.

I remember the dismay I felt as I was building my 1803 Harper's Ferry from the Track of the Wolf's Special Projects Kit (Translation: The Rifle Shop Kit) I discovered that the touch hole for the preinlet stock would have to be drilled into the breech plug. I had to put aside the parts as I tried to figure out how to get everything lined up. The barrel couldn't be moved back as it was tapered and would not fit properly in the barrel channel. I reached out to some very well renowned gun builders. I looked at the notched breeches of original rifles that were in the possession of some of the members of my gun club. I finally heeded the advice of the Mad Monk who instructed me to go ahead and notch the breech. I would have more than enough threads to maintain breech integrity and I would have a direct path to the powder chamber. A vent pick would keep the flash channel clean and there won't be a problem. The rifle is complete and ignition is very fast.

As we can see from many of the breech plugs shown, the threads behind the notch are sound and there is evidence of the rifle being well used.

Thank you @FlinterNick for all the photos.

Fewer Lawyers Back Then!That worked back in the day but here in the 21st century it'll kill ya.

That worked back in the day but here in the 21st century it'll kill ya.

That was sarcasm. I notched a 36 that I built long ago upon the advice of a reputable builder. I'll probably do it again.Many gunmakers would disagree

That was sarcasm. I notched a 36 that I built long ago upon the advice of a reputable builder. I'll probably do it again.

Some here might go full blown apoplectic upon seeing such a notched breech. Serves em right.

Robin

I don’t understand why anybody would be concerned about a notched breech plug.Many of the original barrels I've unbreached were notched.

Enter your email address to join: