I guess I'll jump in because the title of this topic is "Paper patch and grease grooves Bullets" and I'm trying to figure out why anyone would use a grease groove bullet unless that was the only kind they had on hand.

It is the patch that is in contact with the bore so IMO, the important thing to lubricate is the outside of the paper patch.

I once tried lubricating the paper just after I finished wrapping some bullets.

The next day when I got to the shooting range I tried to load one of them.

The lubricated paper tore and wadded up on the muzzles crown as I tried to load it. I tried several others and they too wadded up and tore.

It seems the paper that I'm using soaks up the grease and becomes thicker making the patched bullet larger than the bore. The paper also seems to loose all of its strength.

Using this knowledge, I went back to lubricating the patch just before I load the bullet. Doing that, the paper doesn't wad up or rip or tare.

Based on this I think if someone uses a grease grooved bullet and doesn't put any grease in the grooves, the paper patched bullet should work just fine.

If the person put grease in the grooves before wrapping the paper onto the bullet, by the time he/she gets to the range the paper will have softened and expanded and that would result in the same situation I had.

I'm sure most of you have seen the bullets I use but for those who haven't here's a photo of them.

As you can see, these bullets are made for paper patching. They have no grease grooves and they have a hollow base to fold the paper into.

Wrapped, they measure .399" in diameter. .001 smaller than the bore on my muzzleloading Schuetzen.

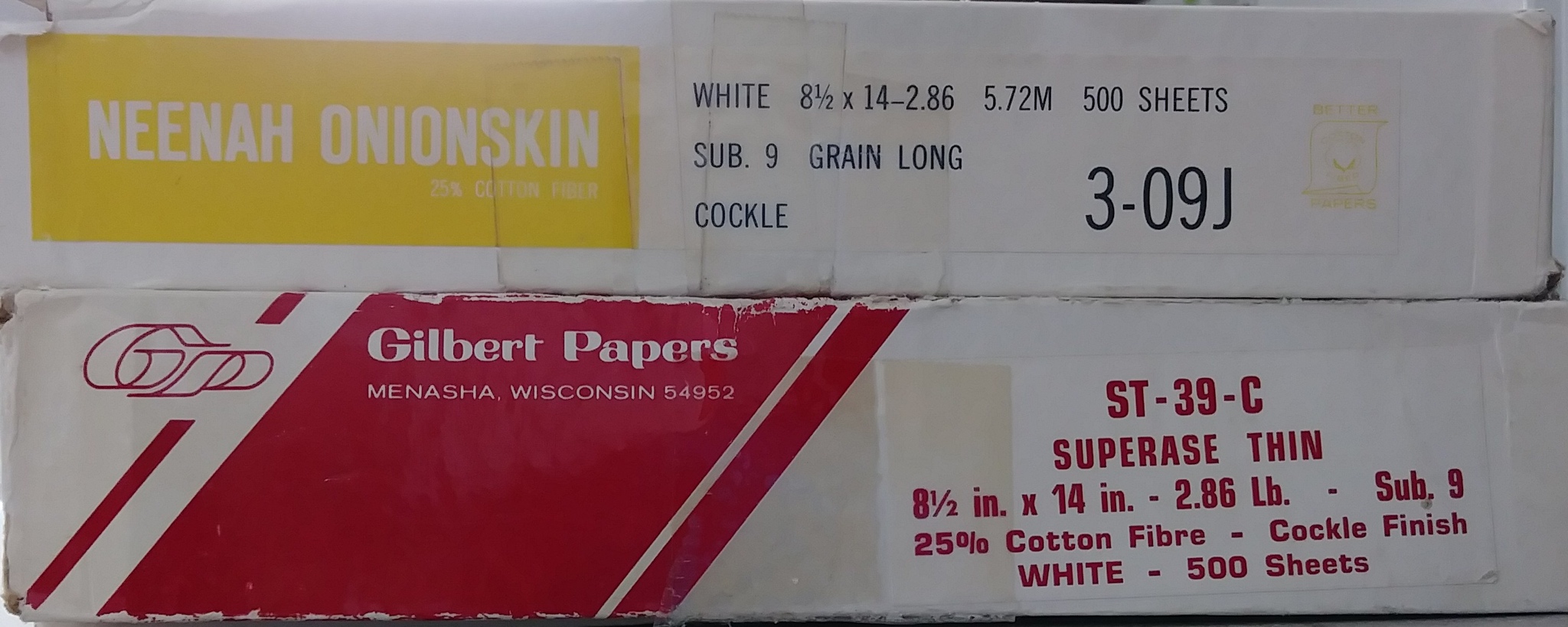

I'm using dress pattern paper, applied wet. When it dries it shrinks to a skin tight fit on the bullet. No glue is required.