If the Minie' balls are just a few thousandths smaller than the guns bore, they can easily become dislodged by a few jolts on the gun.

Trying to patch these with cloth .010 thick could make the slugs darn near impossible to ram down the bore.

With a roundball, very little of it is compressing the fabric. For instance, a .490 diameter ball with a .010 thick patch on it shoved into a .500 diameter bore will only have a contact length where it is trying to engage the bore of .100 long. A bit less than 1/8" where the cloth is actually being compressed.

Also, the spherical shape of a round ball doesn't offer much resistance to being deformed when a lot of pressure is applied to its outside in a small, .100 long length.

A Minie' ball on the other hand has a LOT of surface area trying to engage the bore.

Maybe 3/8" to over 1/2 inch long that's trying to compress that .010 thick fabric.

The cylindrical shape of the Minie' also doesn't provide a lot of space around it to deform into except for the grease grooves.

That makes compressing the bullet a lot more difficult.

These things working together can easily make the Minie' almost impossible to load when it has a cloth patch, even if it is well greased.

As for paper patching, I suppose forming a cup shape with your thumb and then placing the slug into it before ramming it down the bore could work but even this might not be easy if the existing slug is only clearing the bore by 3 or 4 thousandths of an inch and the paper is .003 thick. (There's paper on both sides of the slug so the slug diameter increases twice the paper thickness).

While talking about paper patching, one should notice that many of those who do this, run their patched slugs down thru a sizing die to reduce the patched diameter to just under the bore size.

The other way to paper patch is to use a slug that is Way undersized. For instance, I use a .390 diameter PP slug along with some .0015 thick paper.

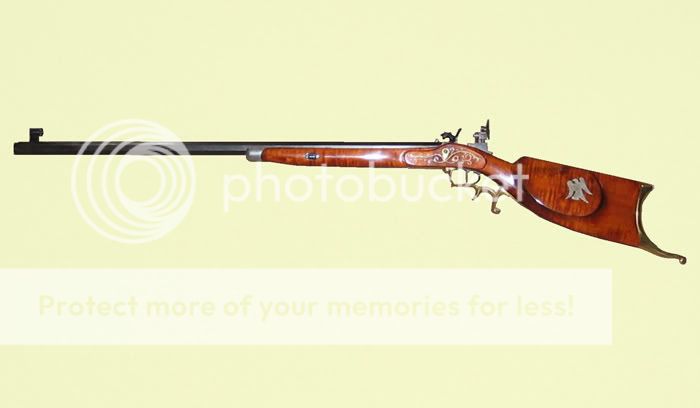

As the paper patch is actually two layers thick, each side of the slug has .003 thickness of paper on it. This increases the patched bullet diameter to .396 which is a nice, easy push fit into my Schuetzen's .400 diameter bore.

The pure lead bullets swell or expand when they are fired so the paper engages the rifling grooves.