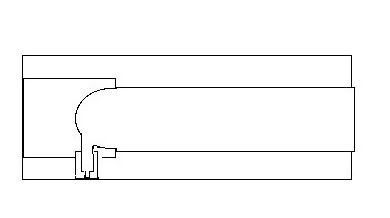

LOL...I think this thread could benefit from some real life hands on experience actually using the modern day modified design of a so called 'Patent Breech'.

Personally used them in several T/C caplocks, then several T/C Flintlocks, in several calibers and gauges, with T/C and GM barrels starting back in 1993... .40/.45/.50/.54rifle/.54smoothbore/.58rifle/.62rifle/.62smoothbore...then continued to use them in custom builds over all the years since then.

The first 10-12 years experience with modern designed Patent Breeches in T/C and GM barrels was so fast, maintenance free, outstanding that when I replaced them all with custom made long guns, I had Patent Breech designed breechplugs made for them in Rice and GM barrels...and sure as Heck wouldn't have spent the money if that wasn't the case.

They are simple, fast, and self cleaning from the back blast out the vent channel...50 shot range sessions and never have to do anything with them...no breech scrapers needed, no vent pics needed, etc...don't even own any. Cleaning up after a range trip or hunt is simple with a cleaning patch around a small caliber bore brush like a .32cal...slides down into the reduced diameter powder chamber, etc.

Personally I don't care what anybody uses, but I do care...as all of us should...that actual facts come out in threads like these, instead of hearsay, 'spin', repeating what's been read on other forums, etc, etc.

And 22 years of personal factual experience with 24,000 - 25,000 shots now is that modern designed Patent Breeches of the past 50 years are outstanding, fast, 100% reliable, and simple / easy to clean.

We may now return to our regularly scheduled broadcasting.

:wink: