barrel_envy

Pilgrim

- Joined

- Jul 2, 2013

- Messages

- 3

- Reaction score

- 0

Hi All

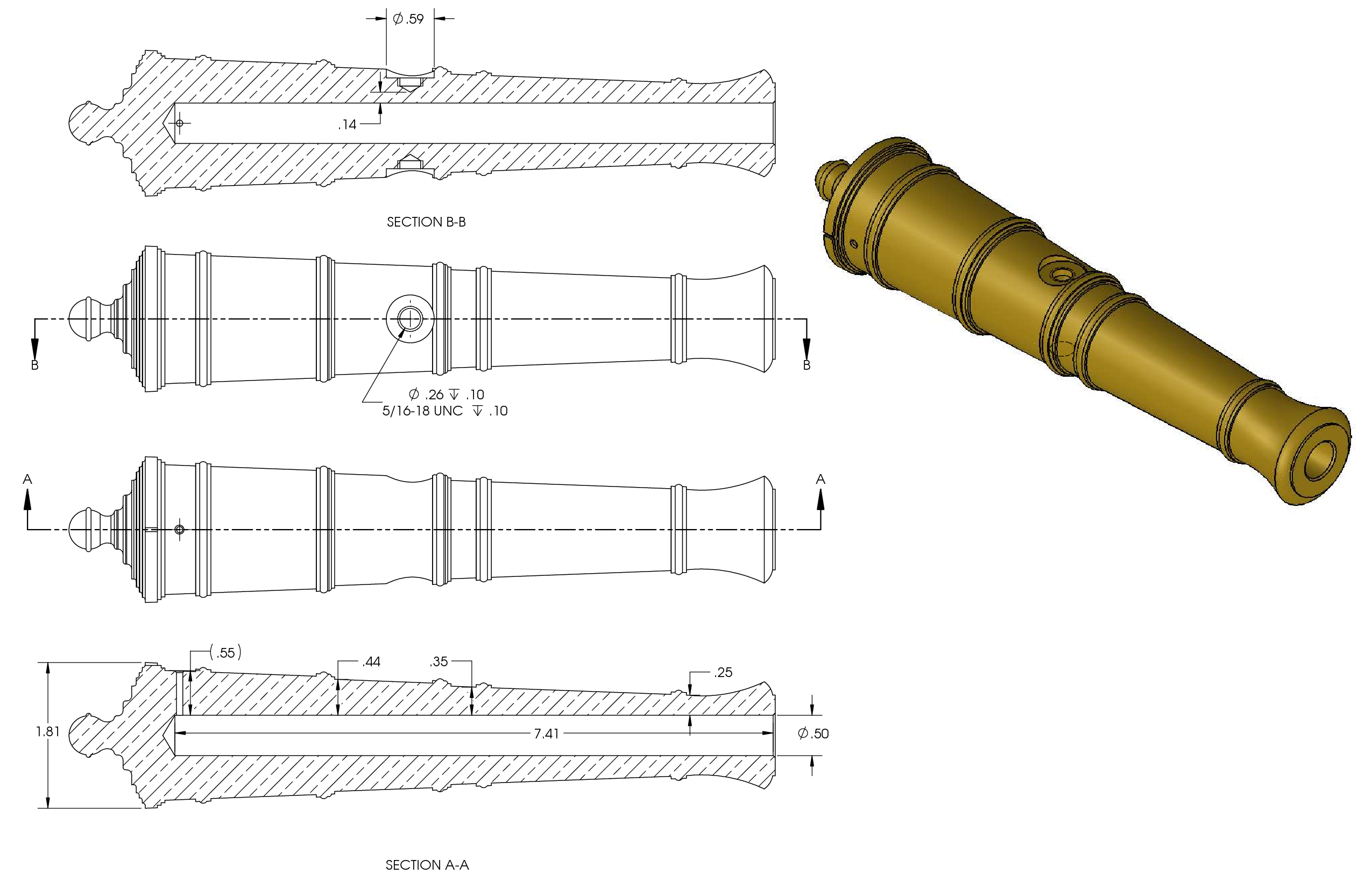

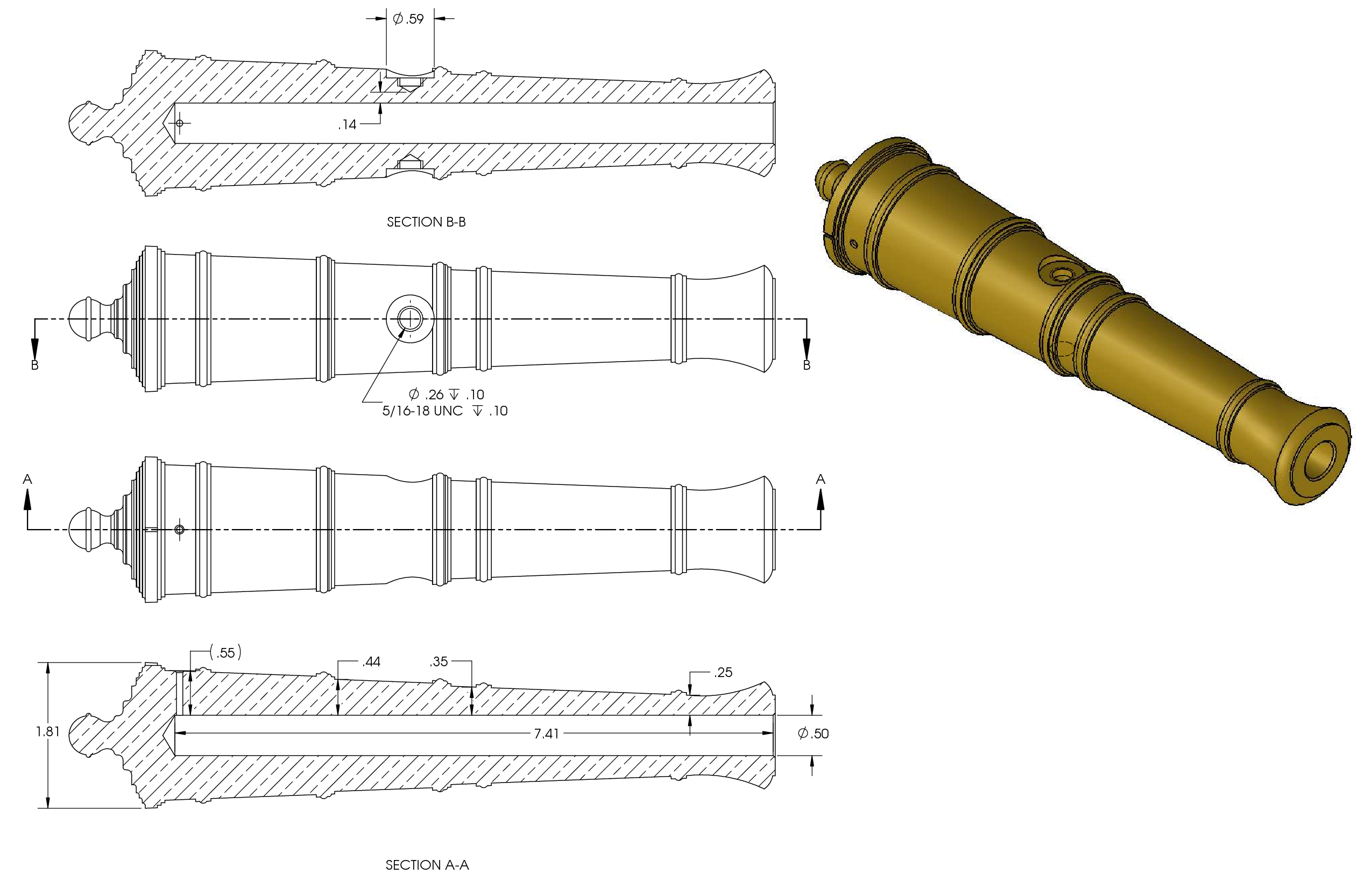

It's my first cannon barrel and I want to run it by the expert folks here :bow: before I invest muchos $$ in material and machining. The primary purpose is for salutes and occasionally gingerly testing it with a lead ball when I get the opportunity to do so safely. I want to make it a good barrel so I have lots of questions for those more experienced than I.

1) I want to make it out of brass, for the color. Is it sufficient to use the common free-machining C360 brass, or should I find a more corrosion-resistant alloy such as Naval or aluminum-brass?

2) Check out my barrel cross-section (see the picture, click for full size), does it look thick enough? I made it greater than one bore thick at the breech, and then it tapers after that.

3) Is my vent in a good location? I figure having it right at the end of the bore without intersecting the drill 'bottom' it will be easiest to clean.

4) Should I bevel/countersink the touch hole and how much?

5) I'm going with a tapped style trunnion mount. (I will attach it to the trunnion with a set screw) Have I left enough metal between the hole and the bore?

6) The yield strength for standard C360 brass is around 45,000psi, so assuming the breech is twice the cross-sectional area of the bore, I figure it could handle a breech pressure around 90,000psi (let's say 75,000 to be safe) before it would deform permanently (but not blow up... that would take another 25% increase in pressure). Is it reasonable to assume my BP charges will stay below 75,000 assuming I follow safe loads and loading procedures?

I appreciate any feedback.

Click picture for full size

It's my first cannon barrel and I want to run it by the expert folks here :bow: before I invest muchos $$ in material and machining. The primary purpose is for salutes and occasionally gingerly testing it with a lead ball when I get the opportunity to do so safely. I want to make it a good barrel so I have lots of questions for those more experienced than I.

1) I want to make it out of brass, for the color. Is it sufficient to use the common free-machining C360 brass, or should I find a more corrosion-resistant alloy such as Naval or aluminum-brass?

2) Check out my barrel cross-section (see the picture, click for full size), does it look thick enough? I made it greater than one bore thick at the breech, and then it tapers after that.

3) Is my vent in a good location? I figure having it right at the end of the bore without intersecting the drill 'bottom' it will be easiest to clean.

4) Should I bevel/countersink the touch hole and how much?

5) I'm going with a tapped style trunnion mount. (I will attach it to the trunnion with a set screw) Have I left enough metal between the hole and the bore?

6) The yield strength for standard C360 brass is around 45,000psi, so assuming the breech is twice the cross-sectional area of the bore, I figure it could handle a breech pressure around 90,000psi (let's say 75,000 to be safe) before it would deform permanently (but not blow up... that would take another 25% increase in pressure). Is it reasonable to assume my BP charges will stay below 75,000 assuming I follow safe loads and loading procedures?

I appreciate any feedback.

Click picture for full size