-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ramrod broken

- Thread starter bkovire

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,538

- Reaction score

- 87

The ramrod needs to be at least as long as the barrel its expected to clean. I always have made my a couple of inches longer, and then, I add a ferrule, to one end, and on that goes a cleaning jag. The result is that my Ramrods extend past the muzzle of the barrel by a few inches. Yeah, they get dirty but that is why I carry cleaning patches, and a rag to wipe my hands( and the rod end) Some guns required that the rod be tapered to fit fully into the stock. Save the pieces of the broken rod, to examine for both length and taper. :thumbsup:

Welcome to the Honorable Society of Dry-Ballers. :hatsoff:

Welcome to the Honorable Society of Dry-Ballers. :hatsoff:

Well, do NOT buy a wooden dowel at your local hardware store. I know the temptation is great because they look like they would work.

The problem with them is they are made out of wood that doesn't bend without breaking and they are machined from a blank. That almost always ends up with the grain of the wood running out the side of the rod.

If this runout exists the wood can easily split along the grain leaving a razor sharp point that will go thru your hand or forearm.

Wood dowels or ramrods with runout look like this:

You can buy rods for making ramrods from Track of the Wolf for a fair price.

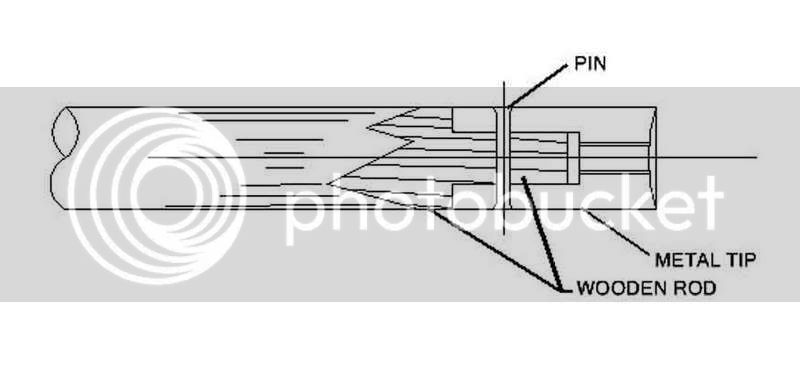

After you get the rod you can use a sharp knife to score a cut around the rod and then use a flat file to reduce the end down to fit into the brass tip.

I recommend using a 1/16 inch drill and a 1/16 inch wire to cross pin the tip in place.

Enlarge the ends of the little hole and put a length of wire thru it.

Peen the wires ends down into the ends of the hole and file the rest flush.

It will look like this when your done.

The problem with them is they are made out of wood that doesn't bend without breaking and they are machined from a blank. That almost always ends up with the grain of the wood running out the side of the rod.

If this runout exists the wood can easily split along the grain leaving a razor sharp point that will go thru your hand or forearm.

Wood dowels or ramrods with runout look like this:

You can buy rods for making ramrods from Track of the Wolf for a fair price.

After you get the rod you can use a sharp knife to score a cut around the rod and then use a flat file to reduce the end down to fit into the brass tip.

I recommend using a 1/16 inch drill and a 1/16 inch wire to cross pin the tip in place.

Enlarge the ends of the little hole and put a length of wire thru it.

Peen the wires ends down into the ends of the hole and file the rest flush.

It will look like this when your done.

ohio ramrod

75 Cal.

- Joined

- Aug 21, 2008

- Messages

- 7,473

- Reaction score

- 2,207

Dixie sells a brown fiberglass rod material at$4.00 for two. If you have or know someone with a lathe to put the ends on you could make one for $10.00. brass ends included.

thank you for the info, i used brass brads on mine, did not want to drill hole through the oak, drilled through brass, kind of messed up, first 2 brads went in ok, the last one bent, so it looks a little funny, no photographs, don,t have dig. cam. :shake:

ohio ramrod said:Dixie sells a brown fiberglass rod material at$4.00 for two. If you have or know someone with a lathe to put the ends on you could make one for $10.00. brass ends included.

Just an FYI as an alternative to a lathe...I just received some of those rods from Dixie and to fit my tips, I measured the distance back from the end that I needed to reduce down, and while rotating the rod in my hand, held that section against the grinding wheel on my bench grinder and that worked fine...only took a minute or two

ohio ramrod

75 Cal.

- Joined

- Aug 21, 2008

- Messages

- 7,473

- Reaction score

- 2,207

It will work if you have a steady hand.Myself I am a real klutz and have a lathe so that is what I use. I am sure the old timers did not have all of the equipment we have available today.

Similar threads

- Replies

- 12

- Views

- 402

- Replies

- 6

- Views

- 500