You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

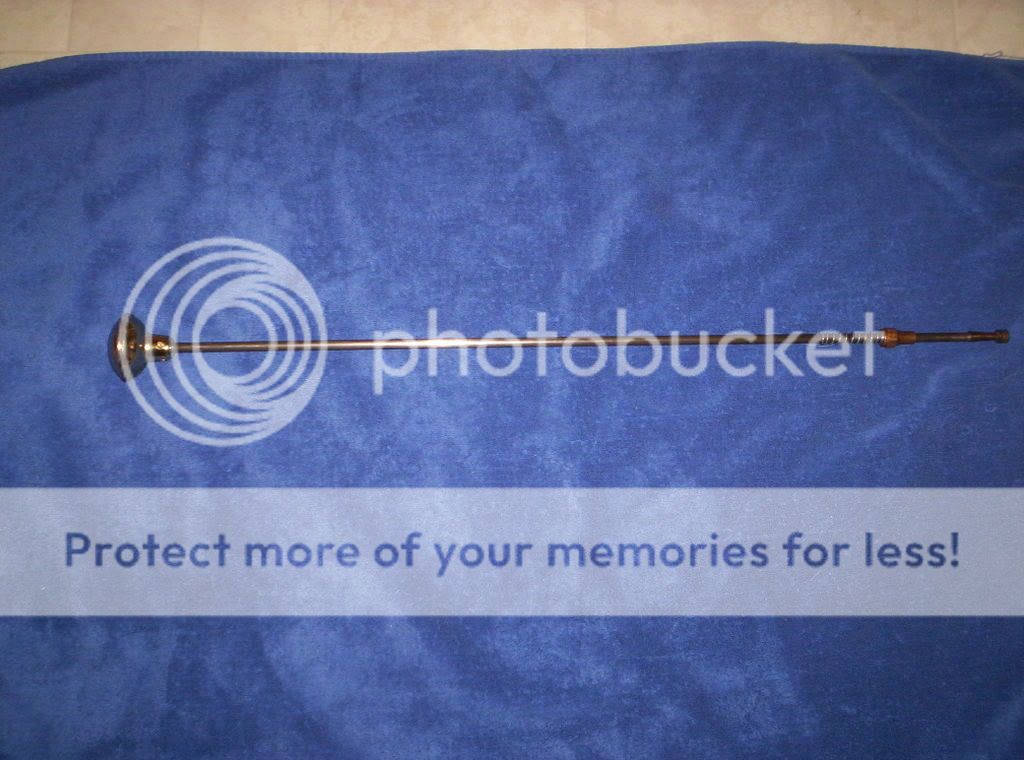

Ramrod seasoning methods?

- Thread starter rtguard

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

longcruise

70 Cal.

I don't think a good piece of ramrod wood needs any seasoning. I've made them from birch dowell, ramin dowel and oak dowell without seasoning and never had a problem. Would use hickory but it's not readily available in my area.

Finally broke a ramrod last year! It was a factory TC rod and after it broke I found a ring cut in the rod by a knife. Remembered at that moment that I had started to shorten the rod for a shorter barreled gun and got distracted and did not finish the job. It broke right where I cut it.

It was a factory TC rod and after it broke I found a ring cut in the rod by a knife. Remembered at that moment that I had started to shorten the rod for a shorter barreled gun and got distracted and did not finish the job. It broke right where I cut it.

I put no finish on a rod. Just left as is, they soon darken from lube and powder staining.

Finally broke a ramrod last year!

I put no finish on a rod. Just left as is, they soon darken from lube and powder staining.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

I have stained Ramrods to make them " match " the stock , and I have then coated them with Tru-oil. I do think it helps keep the rods clean and free of debris, like microscopic bits of silica, which can then wear your bore down.

I seal the rods, now, since I had a new rod, that was not sealed, swell up on a very rainy November day when I was out in it all day long. I could not pull that rod out of the pipes until the wood dried. In effect, I had no rod in the field that day, and the only shot I would have been able to shoot was the one I loaded in the barrel first thing in the morning.

I reserve my wooden ramrods for use in the field. I use my Range rods, made of steel, brass, or aircraft aluminum, for most of the loading chores at the range. The Range rods have muzzle protectors on them.

If you are working with a new piece of hickory, make sure you pin the ferrule you affix to the end to allow you to screw in a cleaning, or loading, jag. I buy jags that have steel threaded screws in them, NOT brass.

And, don't hesitate to use a file to reduce the diameter of the jag to marry to your particular bore diameter. Just chuck the jag in a drill press, or even a hand drill that you can then hold in a bench vise, turn on the drill, and use the file to cut the rings on the jag down to size.

I like a " stepped " jag, with the forward ring the smallest, and the rearmost ring about .010" below bore diameter. The front ring, or " band " should be about .030" smaller than the bore( land to land) diameter. That allows the jag and patch to slide over the crud as they are pushed down the barrel, but bunch up the patch and pull out the crud as the rod is withdrawn.

Sometimes the diameter of the rings have to be reduced a bit more, because the cleaning patches being use make that too tight a fit. Put an angle on the rings, from front to back, so that the rear end of each ring acts like a fish hook, grabbing the patch to pull it out of the barrel.

I don't understand what you mean by " conditioning". There are old wives tales about soaking hickory rods in Kerosene for a month to make them more supple. All that does is make your Ramrod smell like Kerosene for the next 6 months, and you find yourself leaving the rod standing in a corner of the garage during that period. A good hickory rod, with NO run-out of grain, is very flexible-- certainly as flexible as you ever need for a ramrod. It should last a couple of lifetimes, particular if you seal it with a good stock finish oil.

I do wash off the rod after each shooting session, with soap and water. The first couple of years I own a rod, I will annually put an additional coat of stock finish on it, and let it dry before putting it back in the stock. After several years, it seems to only need a new coat of finish every 5 years or so.

I clean the wooden rod so that its feels as smooth as a baby's bottom. That way, I know the wood is not carrying hard substances that will file at the muzzle of my barrel, and destroy accuracy. Oh, I have learned to use my thumb and fore finger on my off-hand to act as a guide when I put the rod down my barrel( when cleaning ), keeping the rod from rubbing against the muzzle as I am pushing it down the barrel. I do the same thing, alternating hands, when I use a hand over hand technique for loading the gun, and center the rod when I am pulling it out of the barrel. I want to leave NO stock finish, and NO wood on the muzzle of the barrel. If I can accomplish that, there will be no rubbing on the inside of the barrel, either.

I seal the rods, now, since I had a new rod, that was not sealed, swell up on a very rainy November day when I was out in it all day long. I could not pull that rod out of the pipes until the wood dried. In effect, I had no rod in the field that day, and the only shot I would have been able to shoot was the one I loaded in the barrel first thing in the morning.

I reserve my wooden ramrods for use in the field. I use my Range rods, made of steel, brass, or aircraft aluminum, for most of the loading chores at the range. The Range rods have muzzle protectors on them.

If you are working with a new piece of hickory, make sure you pin the ferrule you affix to the end to allow you to screw in a cleaning, or loading, jag. I buy jags that have steel threaded screws in them, NOT brass.

And, don't hesitate to use a file to reduce the diameter of the jag to marry to your particular bore diameter. Just chuck the jag in a drill press, or even a hand drill that you can then hold in a bench vise, turn on the drill, and use the file to cut the rings on the jag down to size.

I like a " stepped " jag, with the forward ring the smallest, and the rearmost ring about .010" below bore diameter. The front ring, or " band " should be about .030" smaller than the bore( land to land) diameter. That allows the jag and patch to slide over the crud as they are pushed down the barrel, but bunch up the patch and pull out the crud as the rod is withdrawn.

Sometimes the diameter of the rings have to be reduced a bit more, because the cleaning patches being use make that too tight a fit. Put an angle on the rings, from front to back, so that the rear end of each ring acts like a fish hook, grabbing the patch to pull it out of the barrel.

I don't understand what you mean by " conditioning". There are old wives tales about soaking hickory rods in Kerosene for a month to make them more supple. All that does is make your Ramrod smell like Kerosene for the next 6 months, and you find yourself leaving the rod standing in a corner of the garage during that period. A good hickory rod, with NO run-out of grain, is very flexible-- certainly as flexible as you ever need for a ramrod. It should last a couple of lifetimes, particular if you seal it with a good stock finish oil.

I do wash off the rod after each shooting session, with soap and water. The first couple of years I own a rod, I will annually put an additional coat of stock finish on it, and let it dry before putting it back in the stock. After several years, it seems to only need a new coat of finish every 5 years or so.

I clean the wooden rod so that its feels as smooth as a baby's bottom. That way, I know the wood is not carrying hard substances that will file at the muzzle of my barrel, and destroy accuracy. Oh, I have learned to use my thumb and fore finger on my off-hand to act as a guide when I put the rod down my barrel( when cleaning ), keeping the rod from rubbing against the muzzle as I am pushing it down the barrel. I do the same thing, alternating hands, when I use a hand over hand technique for loading the gun, and center the rod when I am pulling it out of the barrel. I want to leave NO stock finish, and NO wood on the muzzle of the barrel. If I can accomplish that, there will be no rubbing on the inside of the barrel, either.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

The secret to a good Hickory Rod is for the tree to be cut down in the winter, when all the sap is out of the tree trunk. That allows the long grain structure to flex the easiest. I have seen a freshly split out hickory rod, rounded to shape, be bent into a circle without breaking, or showing stress fractures. If the hickory tree is cut in the spring or summer, when the sap is running, then you have to dry the wood for many months, and you still won't have the flexibility needed to do that trick, safely.

There is NO reason why a ramrod should ever need to be bent around into a circle.

Hickory has many admirable properties that made it the choice for tool handles, and other equipment back in the days when everyone lived in a " wood culture ", before iron and other metals became cheap, and readibly available.( Think transportation other than by canoe, or horse.) Depending on what the hickory is going to be used to make, woodworkers would cut trees down at certain, different, times of the year. And, depending on what the hickory would be used to do, the woodcutters would look for trees growing in certain topography in the forests.

Everyone knew how to, and did read the grain structure of the trees by " reading " the bark on the trees. Cutting was hard hand work, expensive, and time consuming. Splitting tree trunks was a much faster way to obtain useable wood. Wood cutters looked for trees with straight grain because its much easier to split. Trees with twisted grain might be used as fence posts, or for a palasade, if tall enough. They could be used "as is" to build a log home, or pen or barn for animals.

There is NO reason why a ramrod should ever need to be bent around into a circle.

Hickory has many admirable properties that made it the choice for tool handles, and other equipment back in the days when everyone lived in a " wood culture ", before iron and other metals became cheap, and readibly available.( Think transportation other than by canoe, or horse.) Depending on what the hickory is going to be used to make, woodworkers would cut trees down at certain, different, times of the year. And, depending on what the hickory would be used to do, the woodcutters would look for trees growing in certain topography in the forests.

Everyone knew how to, and did read the grain structure of the trees by " reading " the bark on the trees. Cutting was hard hand work, expensive, and time consuming. Splitting tree trunks was a much faster way to obtain useable wood. Wood cutters looked for trees with straight grain because its much easier to split. Trees with twisted grain might be used as fence posts, or for a palasade, if tall enough. They could be used "as is" to build a log home, or pen or barn for animals.

rafterob

62 Cal.

Considering it's Hickory I figure a good BBQ rub will do the trick. I'm sorry I can't give out my recipe, it is a closely guarded secret. :grin: I seasoned mine with stain and linseed oil and then paste wax to help shed water.

Billnpatti

Cannon

- Joined

- Aug 11, 2008

- Messages

- 7,340

- Reaction score

- 44

I tried the kerosine soaking method one time but I couldn't see much difference between that and just rubbing the rod with several liberal coats of boiled linseed oil. After managing to break my T/C rod and nearly jamming it into my hand, I quit using wooden rods for anything except for show. For actual use, I have bought synthetic rods. Just be sure to get the correct diameter or they will either stick in the rifle or will fall out if you tip it muzzle down. My range rods are brass and I use a muzzle protector on each one. I also have taken to putting old brass or porceline door knobs on the end of the rods to make it easier to seat a tight ball. Besides, I think the knob sort of dresses up the rod just a bit.

I have soaked rods in kerosene using a piece of PVC with a cap on one end, but really can't say it offered anything over the unsoaked rods, I do put a coat or two of the same finish I use on the stock and now and then I stain them to match the stock, but as I drift more and more to the lazy side of life they will likely not be stained.

tg,tg said:I have soaked rods in kerosene using a piece of PVC with a cap on one end, but really can't say it offered anything over the unsoaked rods...

I use that method most of the time,and the only thing I can say is I have not had one

shatter. On the other hand I am very particular

about the hickory rods I choose to make ramrods from.I may purchase 24 and use 6 for ramrods.

I also replace ramrods often,just because I like to....Go figure

snake-eyes :hmm:

Greenmtnboy

62 Cal.

- Joined

- Dec 10, 2005

- Messages

- 2,582

- Reaction score

- 12

tg said:I have soaked rods in kerosene using a piece of PVC with a cap on one end, but really can't say it offered anything over the unsoaked rods, I do put a coat or two of the same finish I use on the stock and now and then I stain them to match the stock, but as I drift more and more to the lazy side of life they will likely not be stained.

I do the same thing with linseed oil and only soak it for a hour or so then wipe off the excess and lay it out to dry on a sunny deck or in the winter behind the woodstove.

I have had the same field rod for ten years.

Similar threads

- Replies

- 27

- Views

- 2K

- Replies

- 2

- Views

- 139

- Replies

- 14

- Views

- 875