-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ramrod tip

- Thread starter rmatt

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I'm sure there are many ways to do that.

I use a small table saw and carefully roll it over the blade set just high enough to remove a little at a time until the tip slides on the rod.

Otherwise, one would need to cut a line around the rod at the desired spot and then file away the excess.

I always epoxy and pin my tips on.

I use a small table saw and carefully roll it over the blade set just high enough to remove a little at a time until the tip slides on the rod.

Otherwise, one would need to cut a line around the rod at the desired spot and then file away the excess.

I always epoxy and pin my tips on.

Keb

50 Cal.

I score the end with a brake line tubing cutter to depth then use a chisel & file to fit the tip, epoxy & pin.

W/ a sharp knife a cut is made around the dia and a chisel is used to back cut to the knife cut. Then the dia is filed w/ 4 flats and then 8 flats and then the corners are rounded and the RR tip is fitted.

A waxed bolt is screwed in to the bottom of the large dia and epoxy is applied to the tip and RR, pushed together and when setup, a pin is installed.....Fred

A waxed bolt is screwed in to the bottom of the large dia and epoxy is applied to the tip and RR, pushed together and when setup, a pin is installed.....Fred

As said, lotsa ways. I usually just use my pocket knife and whittle. A special tool would be nice if you did a lot of them.

- Joined

- Jun 12, 2005

- Messages

- 8,014

- Reaction score

- 1,021

how you remove the wood is pretty much up to you - these are all good ways (I like flehto's best)

what's really important is that you pin it ... if you don't ....

well, don't ask me how I know :redface:

what's really important is that you pin it ... if you don't ....

well, don't ask me how I know :redface:

Patocazador

54 Cal.

I've got a 3/4" wide grinding wheel that I use to remove the excess while rotating the rod.

Rifleman1776 said:As said, lotsa ways. I usually just use my pocket knife and whittle. A special tool would be nice if you did a lot of them.

This is how I do mine also and then epoxy and pin it.

StewartLeach

40 Cal.

- Joined

- May 12, 2008

- Messages

- 415

- Reaction score

- 1

Gosh, I feel like I've gone high tech compared with some of you guys. I made up a set of guide blocks with aligned sets of holes to just pass 5/16ths, 3/8ths and 1/2 inch rod stock. The blocks are about 12 inches apart. Spouse or daughter runs electric drill clamped to other end of rod while I dress down the working end to just slip on the fitting. Usually turn a section slightly long, then rasp off to bring end of fitting flush with shoulder on the rod stock.

Flehto is so right to recommend blocking the drilled inner passage before applying epoxy. And as everyone has said- drill it crosswise, counter sink a bit, and place a crosspin! Otherwise you will have to go fishing down a blind hole.....

White Fox

Flehto is so right to recommend blocking the drilled inner passage before applying epoxy. And as everyone has said- drill it crosswise, counter sink a bit, and place a crosspin! Otherwise you will have to go fishing down a blind hole.....

White Fox

- Joined

- Nov 26, 2005

- Messages

- 5,203

- Reaction score

- 10,795

Hi,

Pinning is good but you can also use a wedge just like an axe handle. Cut a slot in end of the ramrod after whittling so the tip fits. Then make a small wedge to fit the slot, put glue on the ramrod, and hammer the tip home. The wedge will expand the wood and anchor the tip as well as a pin. That is how the tips on Brown Bess muskets were affixed when wooden rods were used.

dave

Pinning is good but you can also use a wedge just like an axe handle. Cut a slot in end of the ramrod after whittling so the tip fits. Then make a small wedge to fit the slot, put glue on the ramrod, and hammer the tip home. The wedge will expand the wood and anchor the tip as well as a pin. That is how the tips on Brown Bess muskets were affixed when wooden rods were used.

dave

That's a new one on me! I will be giving it a try next time. I usually just pin mine on after filing and checking fit often. I never liked pinning tips on but I didn't know of another way of keeping it on. I usually counter-sink the tip a little bit also.

"A waxed bolt is screwed in to the bottom of the large dia and epoxy is applied to the tip and RR, pushed together and when setup, a pin is installed".....Fred

Can you explain this another way ??

I'm not getting the idea of the waxed bolt and where it goes and what it does..

Kinda dumb about this concept..

thank you .... thom

Can you explain this another way ??

I'm not getting the idea of the waxed bolt and where it goes and what it does..

Kinda dumb about this concept..

thank you .... thom

Hi...the waxed bolt keeps the epoxy out of the threads and the wax prevents the epoxy from "gluing" to the bolt. I screw the bolt in so it's just at the bottom of the larger dia....the total threaded length is "protected" by the bolt.

There are many ways to install a RR tip and seeing I only do this several months apart, I don't need a quicker way.....Fred

There are many ways to install a RR tip and seeing I only do this several months apart, I don't need a quicker way.....Fred

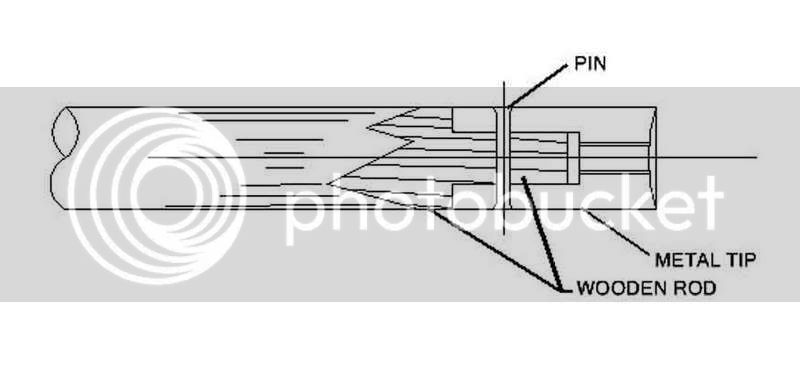

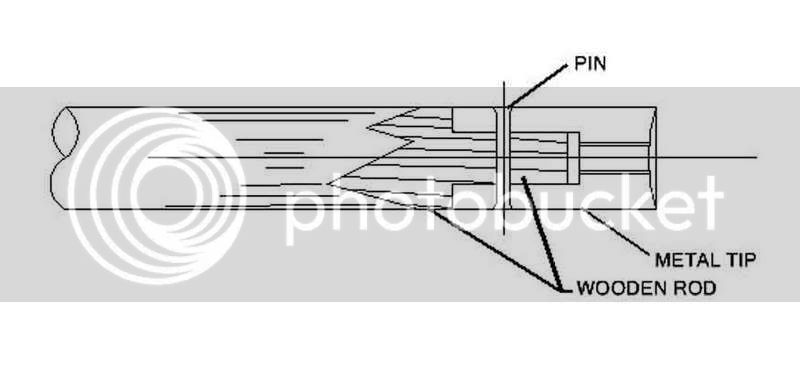

Here's a link to a post about pinning a ramrod tip on.

http://www.muzzleloadingforum.com/fusionbb/showtopic.php?tid/83591/post/83772/fromsearch/1/#83772

And a drawing of what it should look like.

http://www.muzzleloadingforum.com/fusionbb/showtopic.php?tid/83591/post/83772/fromsearch/1/#83772

And a drawing of what it should look like.

Last edited by a moderator:

On a few LRs that had slightly imperfect RR holes which req'd reduced dias, a RR tip w/ thicker walls would have been nice. Normally don't taper the RR and the dia reduction isn't all that great, but have to sort through the tips to find one w/ thicker walls. Minor complaint, but a slightly thicker wall would be handy....Fred

Could be it started as a topic & ended up we washed an elephant. :redface: Have a tendency to get off topic some times. If you goto that link Zonie gave you, it will get your RR done. I use dyed Accraglas Gel to glue mine on, then pin them. Basically same as when I wrote that up, except I was using Microbed at that time.

Keith Lisle

Keith Lisle

I have found a supplier that has the tip I want, then I buy a dozen of each size, so I always have the same type, length & wall thickness. Same way with Jags & ball pullers, etc. Most of the time, I get them from Tip Curtis.

Now at times Tip's may cost a buck more, but the Quality is always there. The jags from some of the venders have too thick of walls & you basically have no wood in the tip to hold it. Also because scrap brass is high, some now are making these Tips & Jags 1/2" shorter & I don't like that. I want them both Long....

Keith Lisle

PS: Seen many a time a guy spend $ 1000. on parts for a rifle & cringe on paying a extra buck for a good ramrod or well made RR tips or accessories. I can assure you, you spend the 1000, the other 3-4 bucks will not hurt at all.

Now at times Tip's may cost a buck more, but the Quality is always there. The jags from some of the venders have too thick of walls & you basically have no wood in the tip to hold it. Also because scrap brass is high, some now are making these Tips & Jags 1/2" shorter & I don't like that. I want them both Long....

Keith Lisle

PS: Seen many a time a guy spend $ 1000. on parts for a rifle & cringe on paying a extra buck for a good ramrod or well made RR tips or accessories. I can assure you, you spend the 1000, the other 3-4 bucks will not hurt at all.