OK. First of all I will state I have not done this with these tools. I am showing & telling based on what I have in hand & the notes with the stuff I bought, and what I have been told by old timers that have freshened barrels, and what I have read.

Anyone that knows more about this, please jump right in.....

These are the cutter heads that are lead or babitt poured in the barrel over the ramrod piece of wood. 4 dif calibers here. 3 have a cutter slot in them, the double one does not, I can't tell you why. I will surmise it was started & not finished. Notice the front of the rod (right side in photo) is cut/shaped to go into a clevis & then a pin retaining it in the clevis.

Hard to get a good photo, but you can make out the rifling & the slot cut in the rod is for the cutter insert.

Cutter insert could look something like this drawing, front has to be pointed & angled down & goes into a inlet shaped like the cutter, into the rod on the Pull side, point being on the Pull Side, so when you pull the tool the front of the cutter cannot rise up. Have not found the actual cutter inserts as have allot of stuff to go thru & no time to do it yet.

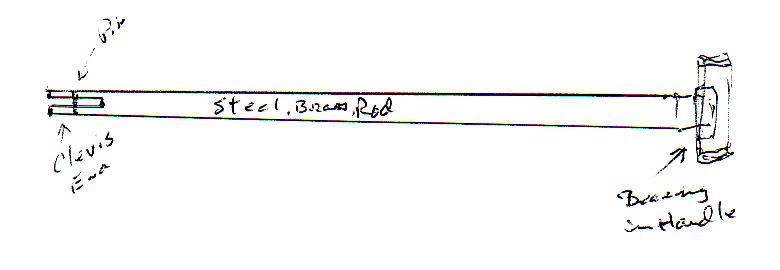

Cutter pull rod I have is as such & steel, with clevis on one end to pin the cutter head to, & should have a bearing in the other end so it free floats & lets the cutter & the cutter head easily ride the rifling to maintain the same groove cut & twist. I saw the rod when I got the stuff, dang if I can lay my hands on it at the moment. :idunno:

You pull cutter head thru each groove. Remove cutter insert, put 1 piece of cigarette paper under the cutter to shim it, repeat cuts on each groove one at a time til they have all been cut/shaved. Lift cutter insert, shim again, repeat procedure.

The reason you use thin cigarette paper is because it is Thin & you are barely shaving the groove. If you put too much in there, it cuts too deep & will bit deep & jam...... now you have the cutter stuck in the barrel...... :shake:

Not... a good situation...

Notes say use LOTS of oil on each groove, as it will bind up if not. The shavings pulled out of it is finer than hair..... It takes many many many passes. How many to clean it all up would depend on the depth of the pits, widths of the grooves, hardness of the steel, quality of the cutter you made, lots of things.

I can tell you it is not a 15 min fix, we are talking about a all day job.... if everything goes right & you don't tear the cutter or cutter head up.

Keith Lisle

Note: If you bore ALL the rifling out, you would have to have a way of indexing each groove to keep them spaced evenly. The rifling machine I have has such a index head & will cut 5,6,7,8 or 9 grooves in a barrel, depending on the bore, width of groove, etc.

I don't know of a way you could do it without some kind of index head to keep them evenly spaced. I do know on the older type of rifling machine like Ken Guy & Steve Bookout uses, the center worm on the machine has grooves cut evenly in it & a pin rides the groove. To go to the next groove, you pull the pin, rotate the center worm, insert pin for the next groove. Repeat procedure, got to next groove & so on...