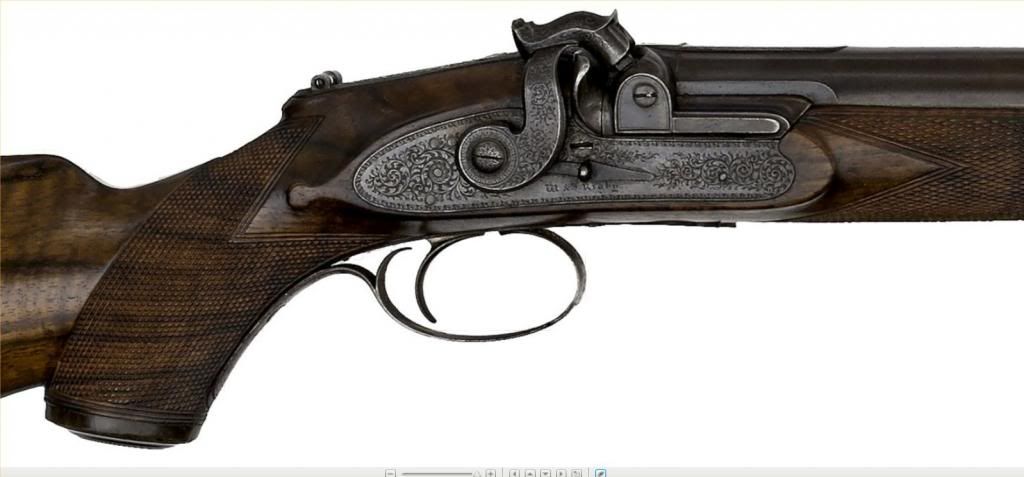

I recently purchased a LRML Rigby English Sporting Rifle with the spur of the hammer broken off.

I have fitted a new replacement hammer that was made from a mold taken from another original Rigby. After about 8 heat and bending sessions I got it to fit like it should and will get it engraved.

My questions is welding a new spur on the original hammer. I am assuming TIG welding will be the ticket, and I know welding cast has some issues. Anyone out there that has done a repair like this?

I would like to salvage the original hammer if I can. Hate not to use it, but I am still going forward with the new replacement, just in case....

thanks

Fleener

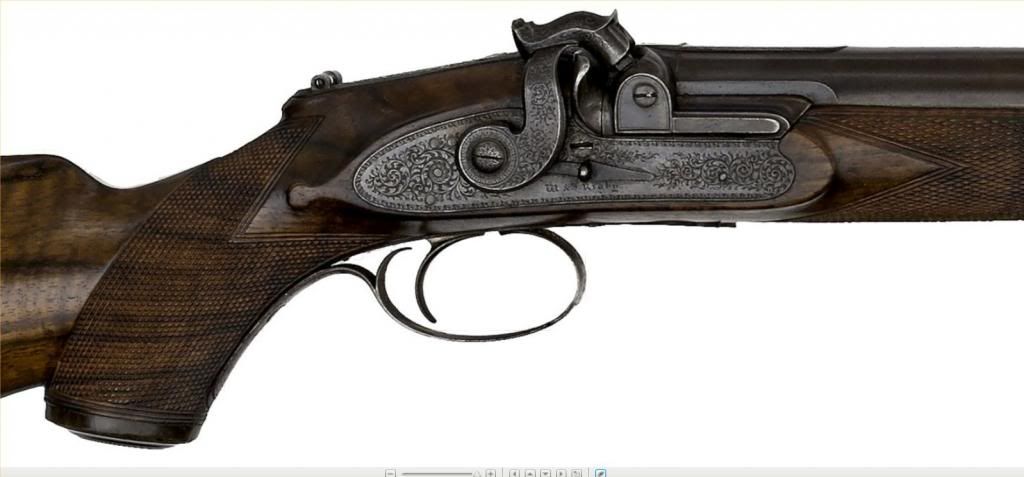

I have fitted a new replacement hammer that was made from a mold taken from another original Rigby. After about 8 heat and bending sessions I got it to fit like it should and will get it engraved.

My questions is welding a new spur on the original hammer. I am assuming TIG welding will be the ticket, and I know welding cast has some issues. Anyone out there that has done a repair like this?

I would like to salvage the original hammer if I can. Hate not to use it, but I am still going forward with the new replacement, just in case....

thanks

Fleener