Many moons ago (1968) I built a Colt 1849 from a Dixie kit (brass frame). I had a lot of fun shooting it but I loaded it to the max when I did not know better. The pistol began to get "loose" and rattle. On my last outing with that gun I had two simultaneous discharges one from the chamber aligned with the barrel and one from an adjacent chamber. On the next loading of the gun I had three simultaneous discharges one from the chamber aligned with the barrel and two from adjacent chambers. I stopped shooting, went back to the house and cleaned the gun and did an examination and found that the recoil shield had nipple marks from where the cylinder moved back and hit it. I retired the gun as a wall hanger. I did have tight fitting balls in the chambers with Crisco over them. I have not experienced any "chain fires" since that time. I do not believe chain fires come from the flash of the burning powder out of the front of the chamber being fired but from the rear - my personal experience. This is one reason why I don't buy brass frame revolvers - yes- I know that I was the cause of my chain fires by overloading that little revolver but this lesson sticks with me to this day, thank God that no one was hurt :bow: .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Size of Felt Wads?

- Thread starter glw

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 25, 2011

- Messages

- 9,632

- Reaction score

- 4,775

I have never had a chain fire in nearly fifty years of shooting black powder revolvers and can't imagine subjecting one of my guns to such abuse trying to make it happen.

I am rather certain it primarily happens from the rear when nipples get burned out and the hammer is blown off the nipple at discharge releasing a large amount of flame under the recoil shield and igniting any loosely capped or de-capped live chambers in the vicinity.

It works just like a flash hole in a flint lock that can often be fired with no prime in the pan.

I am rather certain it primarily happens from the rear when nipples get burned out and the hammer is blown off the nipple at discharge releasing a large amount of flame under the recoil shield and igniting any loosely capped or de-capped live chambers in the vicinity.

It works just like a flash hole in a flint lock that can often be fired with no prime in the pan.

The only chain fire I have observed in 50+ years of shooting revolvers happened to my brother many moons ago. The cylinder was getting hard to turn due to fouling so he decided to spray it with WD-40.:youcrazy: It did free up the cylinder and he loaded all six. The first shot all six went off simultaneously. No one hurt but he did have to go change his shorts.

Well now we are talking about chain firing. First- on the wads- as already said- soak the felt in the lube and let it set up- it's then easy to punch/cut out the wads.

On the wads preventing a chain fire, I've often thought myself about the shaved ring of lead. Off hand it seems like a tight fit so how can fire seep around past the ball and cause a chain firing? The other thing is that during the Civil War combustible cartridges were used by the millions and they didn't have a wad and they didn't have grease put over the ends of the chambers and yet I haven't read that much about chain firing. I think a chain firing can happen several ways but I believe the primary cause is loose caps and open nipples. When we discussed this a year back it was found that those that snapped caps on unloaded cylinders at the start of the day burned off any oil on the nipples but a high percentage of guys that had a chain firing didn't do this and the chain firing occurred on the first loaded cylinder of the day- the conclusion was maybe a greasy nipple helped cause the cap to pop off during recoil. Interesting the guy that sprays with the WD-40 had a chain firing.

So why do we grease the ends of the chambers? Beats me- that's what I was told to do. Then it came out that after a shot or two the remaining chambers had all the grease burned out so they were being shot with no grease at the ends. I switched to wads.

On the wads preventing a chain fire, I've often thought myself about the shaved ring of lead. Off hand it seems like a tight fit so how can fire seep around past the ball and cause a chain firing? The other thing is that during the Civil War combustible cartridges were used by the millions and they didn't have a wad and they didn't have grease put over the ends of the chambers and yet I haven't read that much about chain firing. I think a chain firing can happen several ways but I believe the primary cause is loose caps and open nipples. When we discussed this a year back it was found that those that snapped caps on unloaded cylinders at the start of the day burned off any oil on the nipples but a high percentage of guys that had a chain firing didn't do this and the chain firing occurred on the first loaded cylinder of the day- the conclusion was maybe a greasy nipple helped cause the cap to pop off during recoil. Interesting the guy that sprays with the WD-40 had a chain firing.

So why do we grease the ends of the chambers? Beats me- that's what I was told to do. Then it came out that after a shot or two the remaining chambers had all the grease burned out so they were being shot with no grease at the ends. I switched to wads.

"So why do we grease the ends of the chambers? Beats me- that's what I was told to do. Then it came out that after a shot or two the remaining chambers had all the grease burned out so they were being shot with no grease at the ends. I switched to wads."

Grease, that all depends on the composition and mixture. Using Crisco in Texas in August is like using 3 in 1 oil in August for a lube on the end of the cylinder, does not work.

What lube I shoot in Phoenix when it's cold

(25 to 50 degrees) does not work in Brady, TX when it is 100 or above. Phoenix lube pours out the cylinders after one shot at Brady, very messy and runny.

Kind of like vehicle motor oils in Chicago and Phoenix, need to think where you are.

In all honesty, shooting revolvers does take a bit on thought when using lubes, does it not depending on ambient temps.

Grease, that all depends on the composition and mixture. Using Crisco in Texas in August is like using 3 in 1 oil in August for a lube on the end of the cylinder, does not work.

What lube I shoot in Phoenix when it's cold

(25 to 50 degrees) does not work in Brady, TX when it is 100 or above. Phoenix lube pours out the cylinders after one shot at Brady, very messy and runny.

Kind of like vehicle motor oils in Chicago and Phoenix, need to think where you are.

In all honesty, shooting revolvers does take a bit on thought when using lubes, does it not depending on ambient temps.

- Joined

- Dec 25, 2011

- Messages

- 9,632

- Reaction score

- 4,775

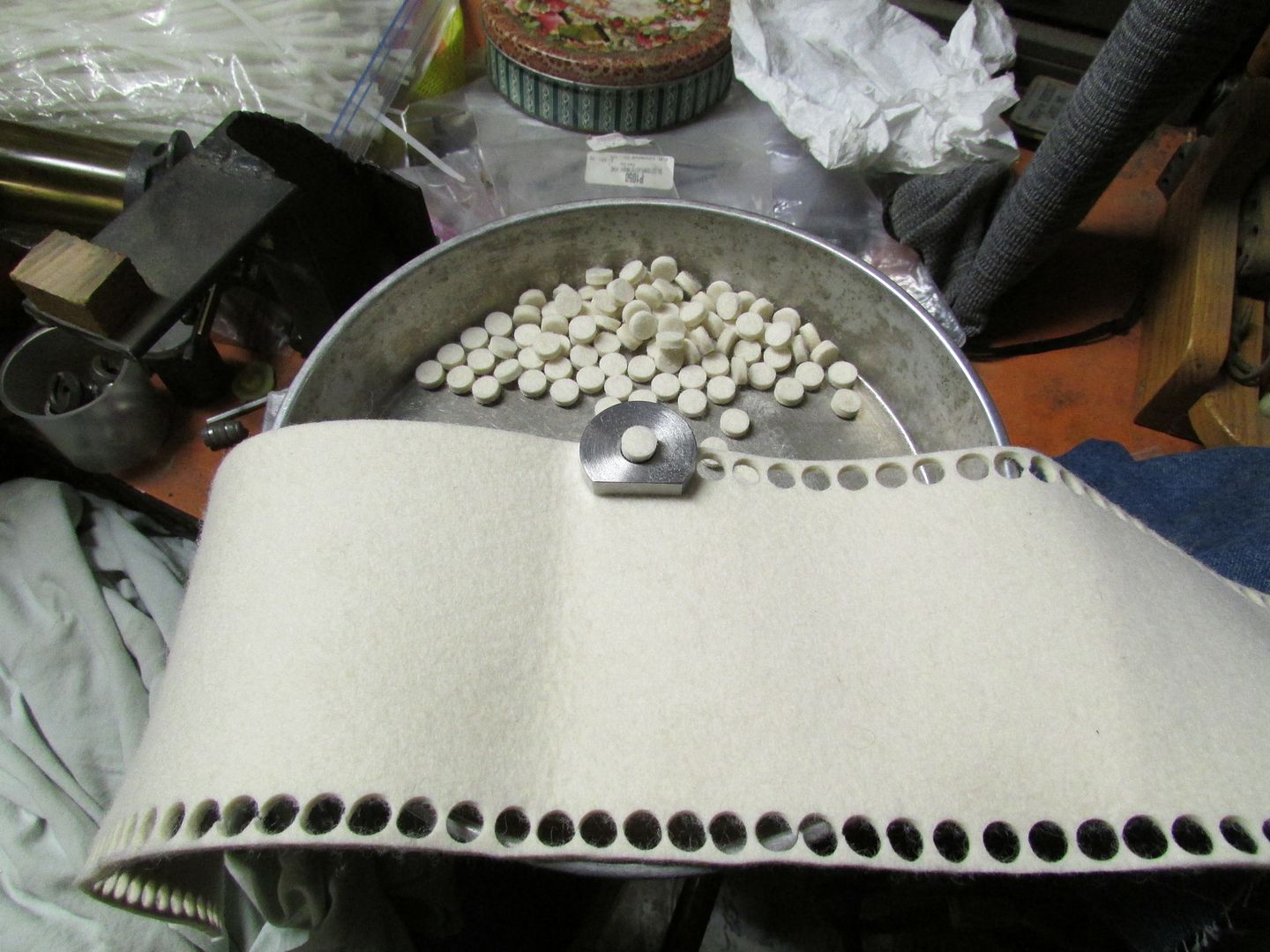

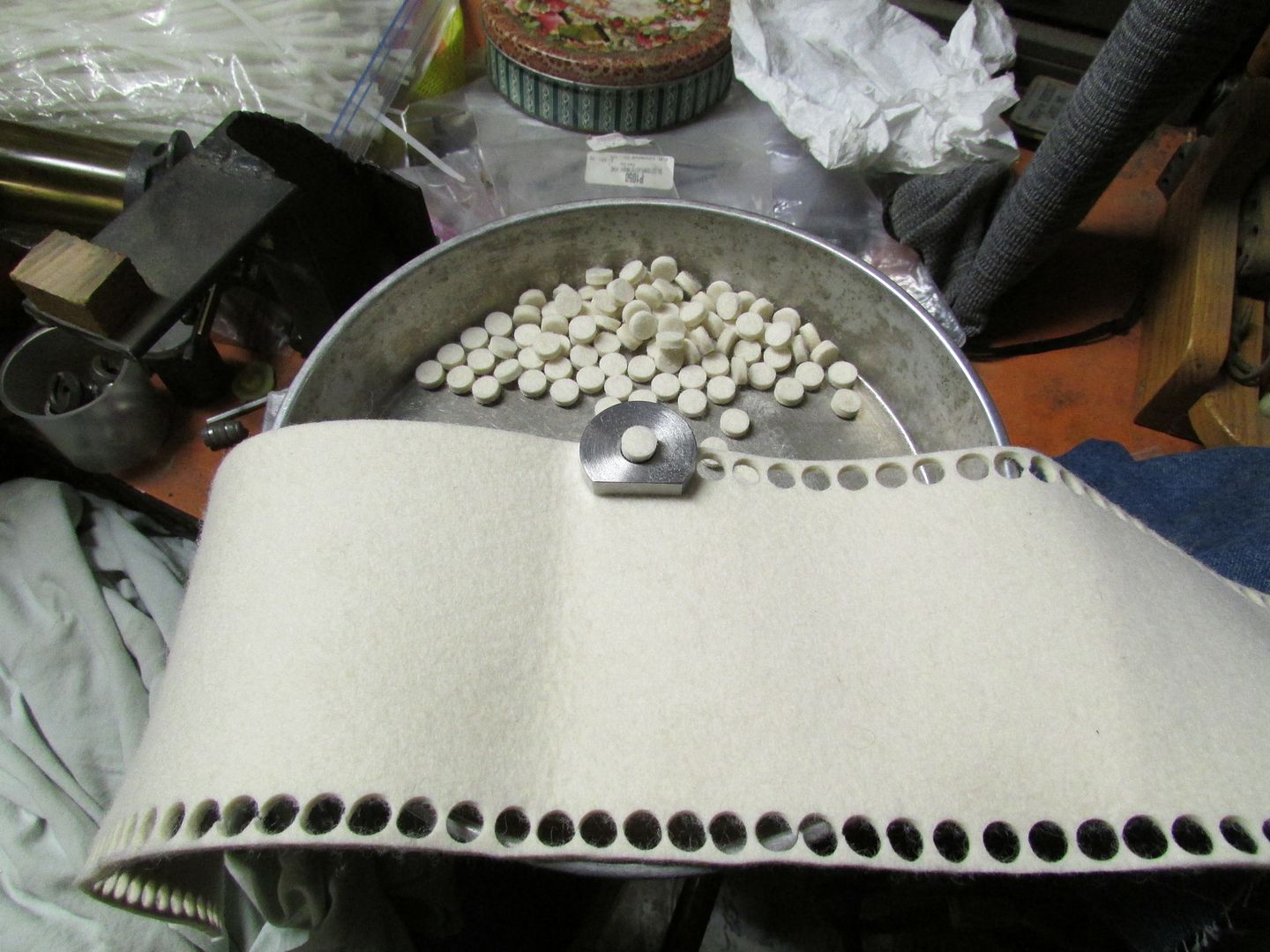

Made my first felt wads today from the 1/8 inch Durofelt I took delivery of earlier in the week.

I first had to chuck up the wad punch I made in the mill an cut the slot larger to accommodate the thicker felt.

Works great and is fun to do, sort of like popping bubble wrap, once you get started it's hard to quit.

This is the set up in the loading press with a cake pan to catch the wads as they pop out the top.

Copied the dies from the ones made by Fred Cornell and modified them a bit for personal needs. Mike D.

I first had to chuck up the wad punch I made in the mill an cut the slot larger to accommodate the thicker felt.

Works great and is fun to do, sort of like popping bubble wrap, once you get started it's hard to quit.

This is the set up in the loading press with a cake pan to catch the wads as they pop out the top.

Copied the dies from the ones made by Fred Cornell and modified them a bit for personal needs. Mike D.

- Joined

- Dec 25, 2011

- Messages

- 9,632

- Reaction score

- 4,775

Any idea of a dry lube formula to try on or in these felt wads? Have plenty of grease lube formulas but don't think I have ever seen one for dry lube. Mike D.

The only "dry" lube I can think of is that used by some on patches - a mix of water and water soluble cutting oil, soak the wads and then let the water evaporate, supposedly leaving them with just a trace of oil (hence the term "dry" I guess).

Nice setup, btw. Any chance of some details of the punch?

Nice setup, btw. Any chance of some details of the punch?

- Joined

- Dec 25, 2011

- Messages

- 9,632

- Reaction score

- 4,775

I'll take some macro shots of the die and punch in the next day or so. It is threaded for a normal loading press in this case an RCBS Rockchucker and the punch is set up to go into a shell holder.

Billnpatti

Cannon

- Joined

- Aug 11, 2008

- Messages

- 7,340

- Reaction score

- 44

That is a real dandy device. Is it made from scratch or did you modify another die somehow? From communicating with you and seeing your posts, I'm going to guess that you made it from scratch on a lathe. If you started with a hunk of steel and turned that fine punch out using a lathe and mill, I am impressed. I've never seen anything like it. :thumbsup: :hatsoff:

- Joined

- Dec 25, 2011

- Messages

- 9,632

- Reaction score

- 4,775

I'm to cheap to buy anything I can make Bill. The ideas and things I learn from all the good folks on these forums is the real gold mine and treasure trove.

If I remember right the die is made of 4140 and the punch 0-1 tool steel. I did not harden either and they have worked fine for several years punching out plastic, veggie gasket , milk carton and now felt wads.

I was worried they would warp out of line if I hardened them as I fit the punch tight enough to pop from suction when pulled out.

So far they have lasted well without hardening so have not really seen the need to do so. Mike

If I remember right the die is made of 4140 and the punch 0-1 tool steel. I did not harden either and they have worked fine for several years punching out plastic, veggie gasket , milk carton and now felt wads.

I was worried they would warp out of line if I hardened them as I fit the punch tight enough to pop from suction when pulled out.

So far they have lasted well without hardening so have not really seen the need to do so. Mike

- Joined

- Dec 25, 2011

- Messages

- 9,632

- Reaction score

- 4,775

By snappers that may work! I have some moose milk I made several years ago and have not used up. Perhaps I will soak some wads in it ,dry them out in the hot sun and see how they work.

Thanks for the idea. Mike

Thanks for the idea. Mike

- Joined

- Dec 25, 2011

- Messages

- 9,632

- Reaction score

- 4,775

In practice the wads are punched out of the square of felt all around the perimeter then the holes are trimmed off with a utility knife against a steel ruler on a cutting board and your ready to punch out another bunch of wads. Mike

Billnpatti

Cannon

- Joined

- Aug 11, 2008

- Messages

- 7,340

- Reaction score

- 44

There is no doubt that you are a gifted and talented man.

Poor Private

58 Cal.

- Joined

- Feb 25, 2007

- Messages

- 2,073

- Reaction score

- 22

Yepper I have joined this club of HF punches.wicket said:I use felt wads formed with a punch i purchased as part of a set from Harbor Freight, it's 3/8" bore which works fine for me. I soak the wads in the lube that Gatofeo promotes online, and find the wads fit the chambers of my Pietta Navy quite well, haven't had a chainfire yet, and the bore accumulates fouling more slowly.

Obviously a punch could be made in any diameter desired,but i don't think diameter is all that critical. The wad probably deforms under pressure when the chamber fires, hugging the bore.

- Joined

- Dec 25, 2011

- Messages

- 9,632

- Reaction score

- 4,775

smoothshooter

50 Cal.

Few things matter less than wad size when shooting percussion revolvers. I have used .36 caliber wads in .44 caliber,.44 wads cut in half in .36 caliber, as well as square wads and round wads seated edgways just to prove a point with no ill effects. The only purpose of the lubricated wad is to soften fouling. I quit using grease over the chambers years ago because of the mess. This does not really matter, I suppose, if you are just playing around or shooting from a table or bench, which is fine; but if you actually carry your revolver as a "working gun" for more serious purposes in a holster and shoot it a lot, you quickly figure out what works best with the least hassle as most of our ancestors did. IF THE BALLS SHAVE LEAD WHEN THEY ARE BEING SEATED, NO CHAIN-FIRE WILL BE CAUSED BY ANYTHING HAPPENING AT THE FRONT OF THE CYLINDER. -Smoothshooter

Billnpatti

Cannon

- Joined

- Aug 11, 2008

- Messages

- 7,340

- Reaction score

- 44

Yep, I'd sure love to have you make one for me but I know it would not be cheap. Lots of work there. I'll just keep punching mine with my hollow punch. It works fine for no more wads than I need at a time. That is one finely made piece of equipment that you can rightly be proud of.

BTW, the spring that you made for my mule ear lock is working like a charm and that rifle has become my "go to" rifle.

BTW, the spring that you made for my mule ear lock is working like a charm and that rifle has become my "go to" rifle.

I'm interested on the shaved lead- no chain fire theory. I wonder if some sort of test could be devised. Safety would be first of course but take the cylinder out of the gun and mount it on a rod, etc. and then pass a propane torch over the end and see if you can create a chain fire- the trouble is, if you do create a chain fire- the balls will shoot out which is a safety isse. There's that famous photo of a confederate cavalry man (Maddox?) and the balls are visible- no lube. If lube had been used then in all the artifacts from the Civil War there would be containers, etc. To my knowledge there are none.

- Joined

- Dec 25, 2011

- Messages

- 9,632

- Reaction score

- 4,775

Well good, that piece of wire I used to wind the coil was just barely long enough and I think I'm out of that diameter and need to pick up some more for stock.

Yeah, I'm not a fast machinist and remember that die and punch took me several evenings work.

I've only made a couple of them for my personal needs and could never charge what they cost me in time and material.

They can be purchased last I knew from Fred Cornell who makes them commercially. Mike

Yeah, I'm not a fast machinist and remember that die and punch took me several evenings work.

I've only made a couple of them for my personal needs and could never charge what they cost me in time and material.

They can be purchased last I knew from Fred Cornell who makes them commercially. Mike

Similar threads

- Replies

- 28

- Views

- 1K