duelist1954

40 Cal.

- Joined

- Jun 27, 2011

- Messages

- 430

- Reaction score

- 72

I’ve been working on a smoothbore round ball test by shooting both patched and bare round balls with both 2Fg and 3Fg Goex powders.

Some of you may recall that a few months ago I took a survey here, and on some other muzzleloading sites to see how you shoot your smoothbores. For the test I shot the powder charges that came up as the most popular in my on-line survey.

I shot from the bench at 50 yards because virtually every load shoots a decent group at 25 yards, you have to get out to 50 to 100 yards before you really see what a group looks like.

I found that my results don’t always back up conventional wisdom. I suspect some of you will be getting out your scalping knives when you see my results. All I can say is that these are the results for a particular gun, and particular shooter on a particular day. Your results may vary.

So, before you unlimber your slings and arrows, I recommend you go to the range and shoot your pet load from the bench at 50 yards for a group. Then shoot my load of 110 grains of 2Fg under tow-.610 ball-tow, or 110 gr 2Fg Goex under 0.015” patch./0.580” ball, and see how your load does head to head vs mine”¦then come after me. If you do this, you’ll either feel vindicated when your load comes out on top, or you’ll have a new pet load”¦either way, you win.

So here are some take-aways:

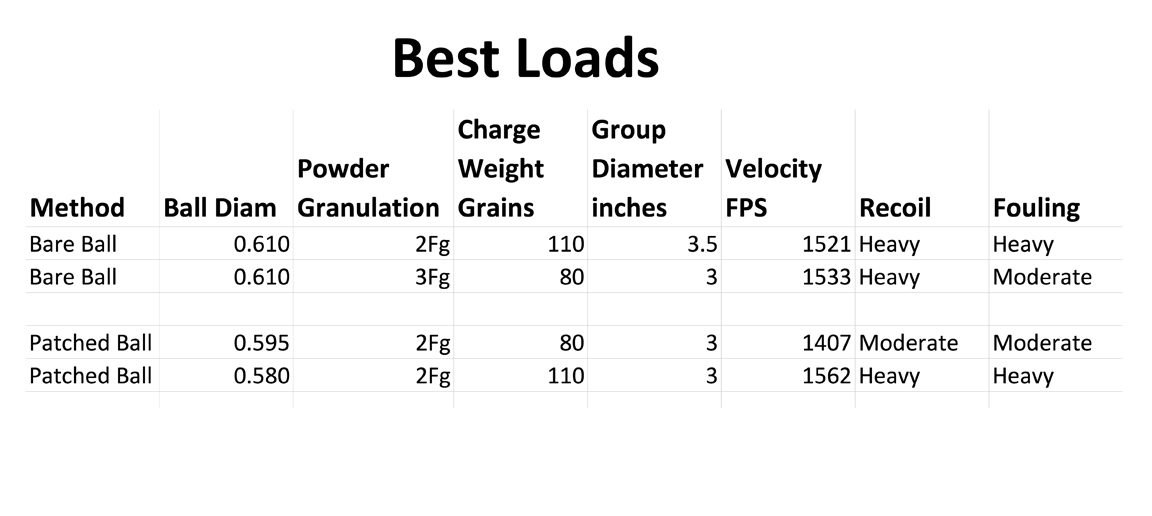

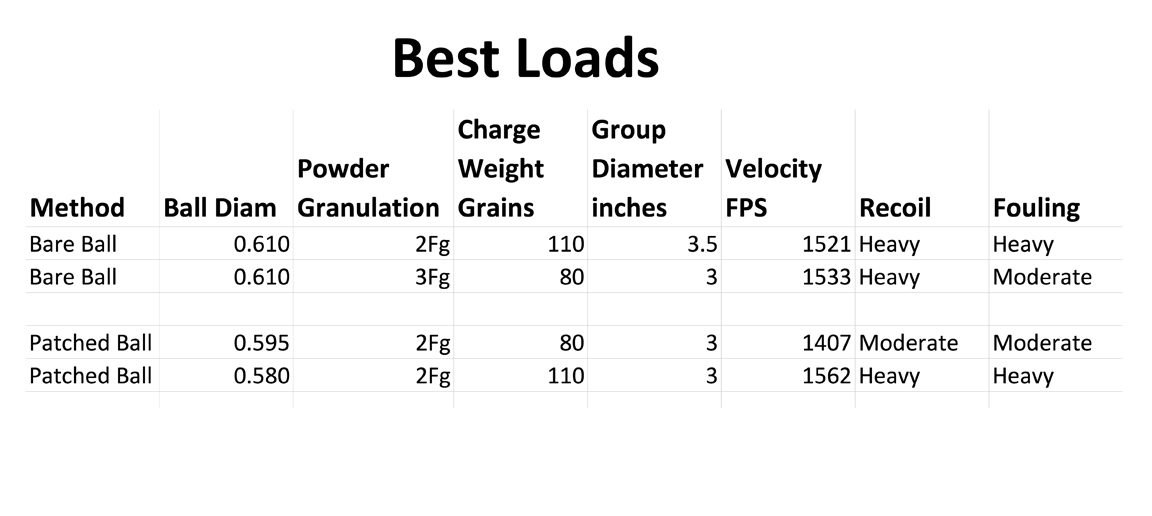

1. The best patched ball load tested, and the best bare ball load tested, turned in exactly the same group.

2. 2Fg out-performed 3Fg with both bare balls and with patched balls

3. A tight ball/patch combo was not the most accurate shooter.

4. A looser ball/patch behaved just like a bare ball”¦liked bigger powder charges of 2Fg better than lighter charges.

5. As with bare balls, 3Fg builds pressure faster than it builds velocity with bigger loads.

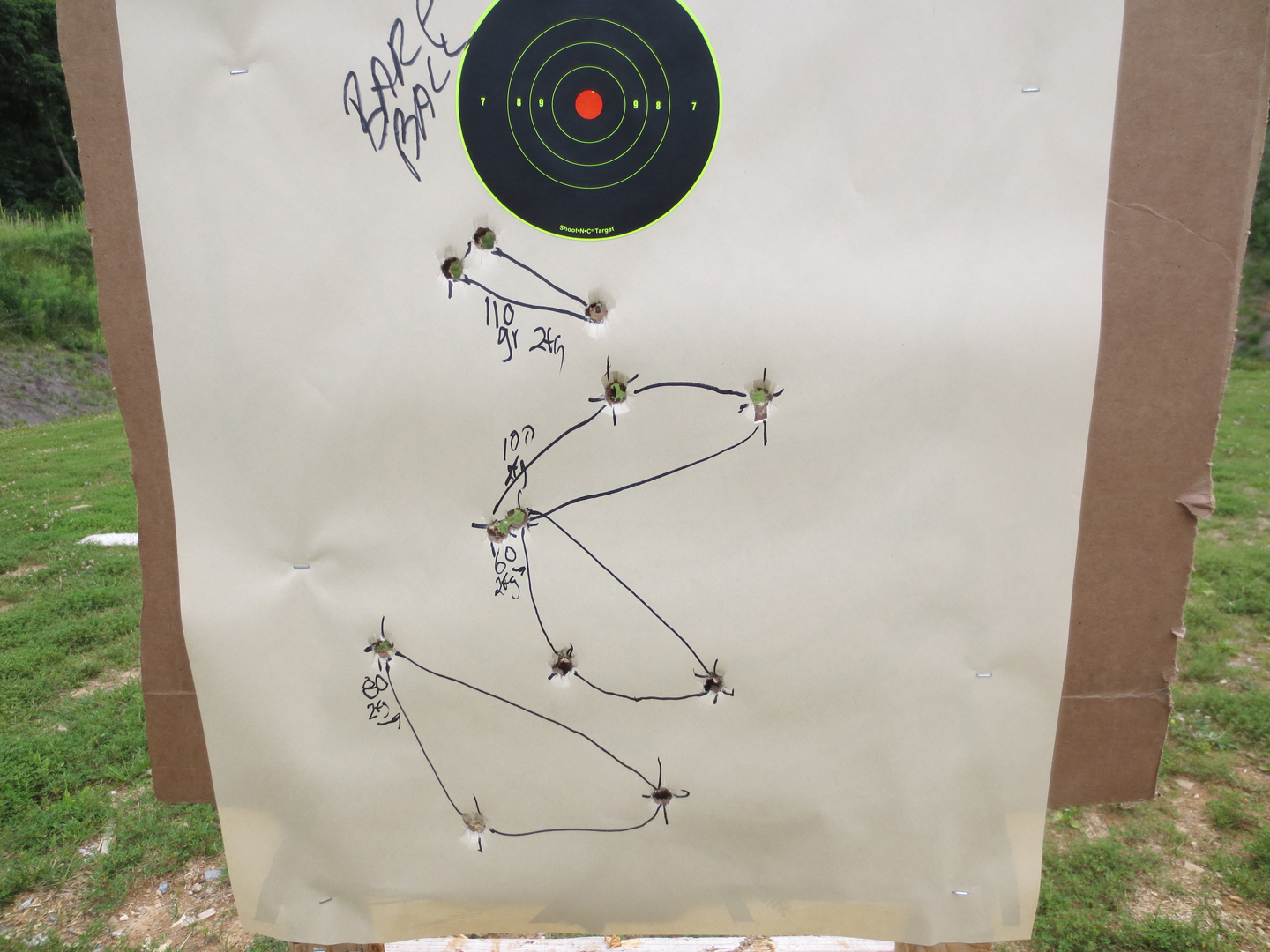

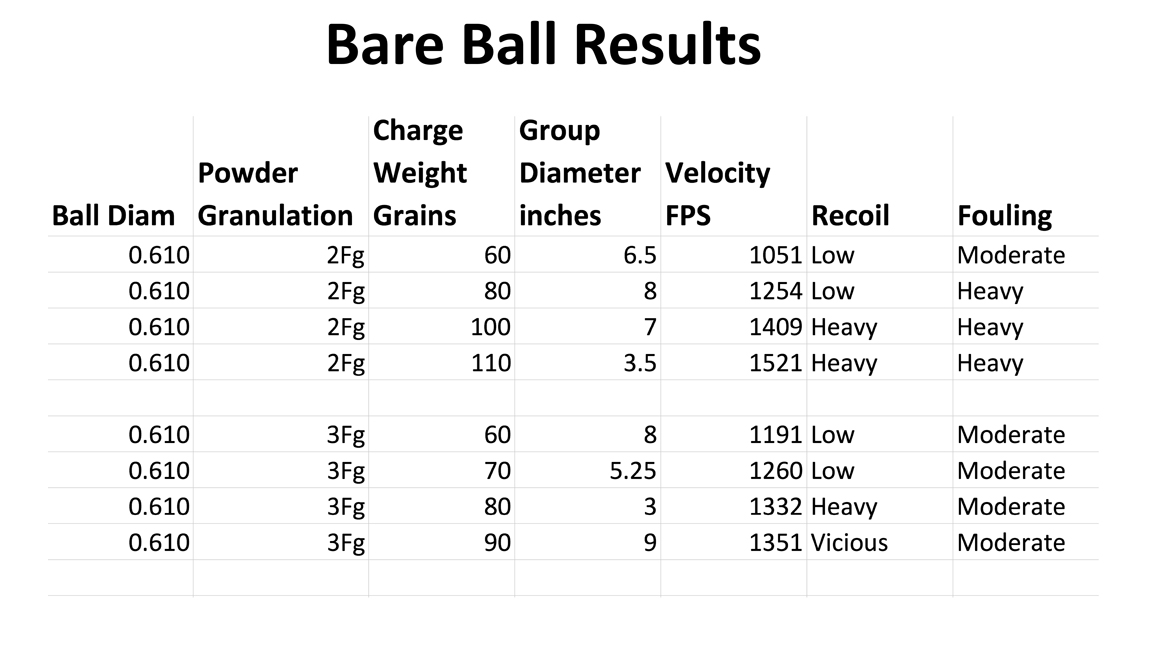

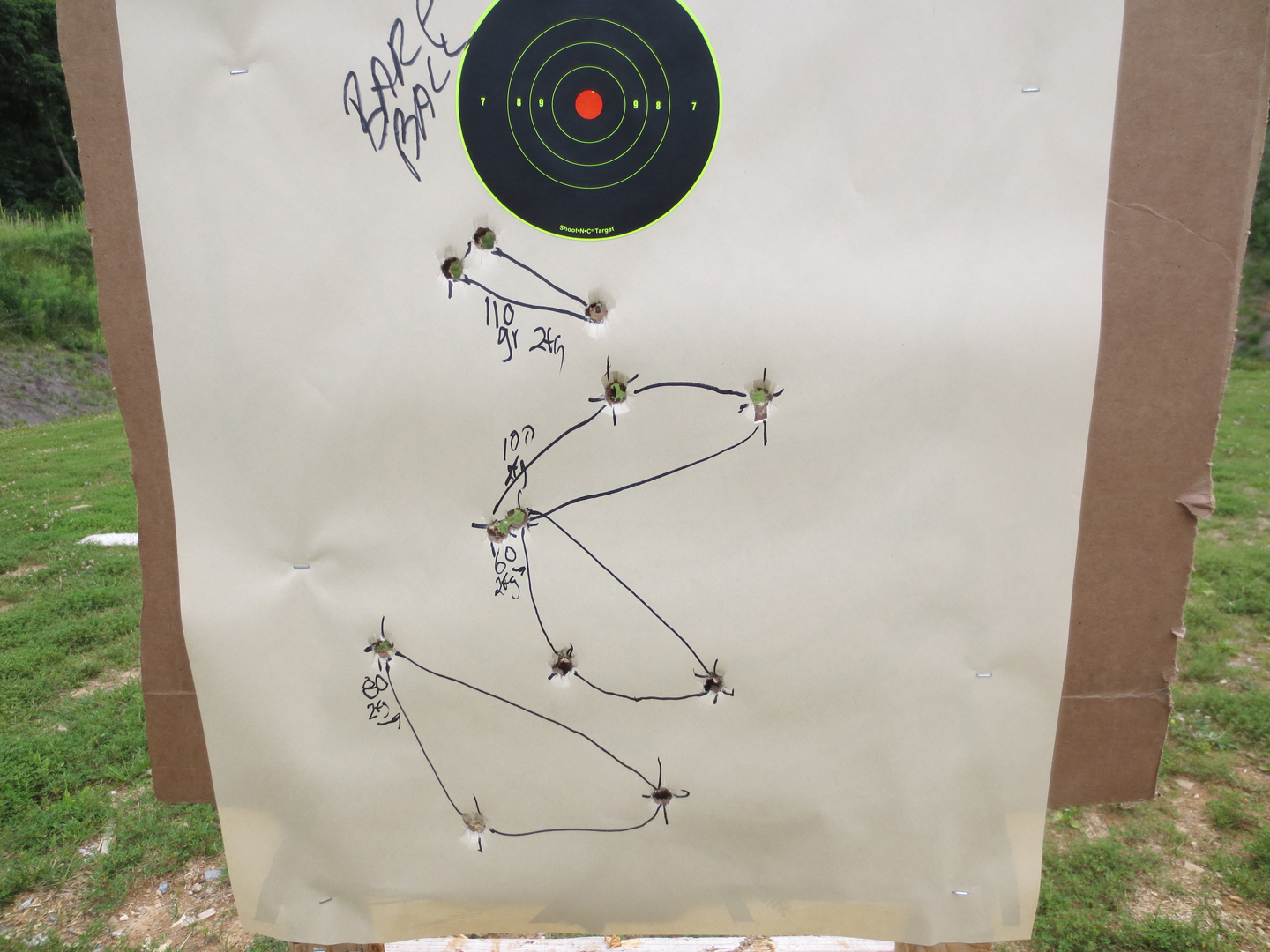

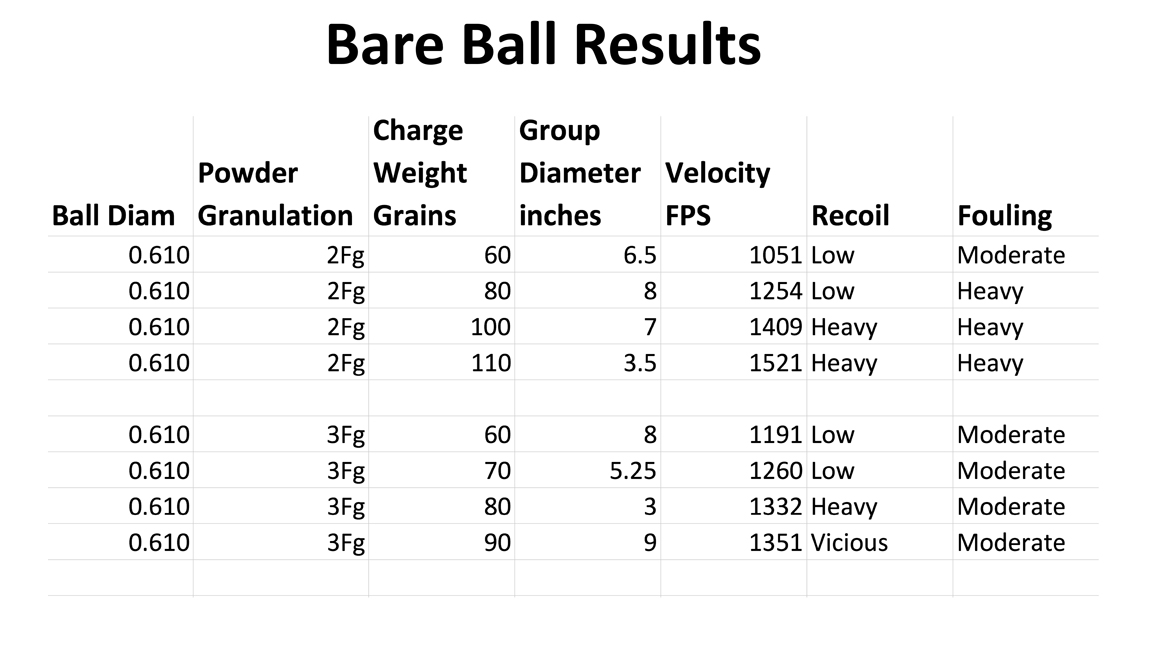

For the bare ball test I shot .610-inch balls wadded with tow. My best groups were with 110 grains of 2Fg, and 80 grains of 3Fg.

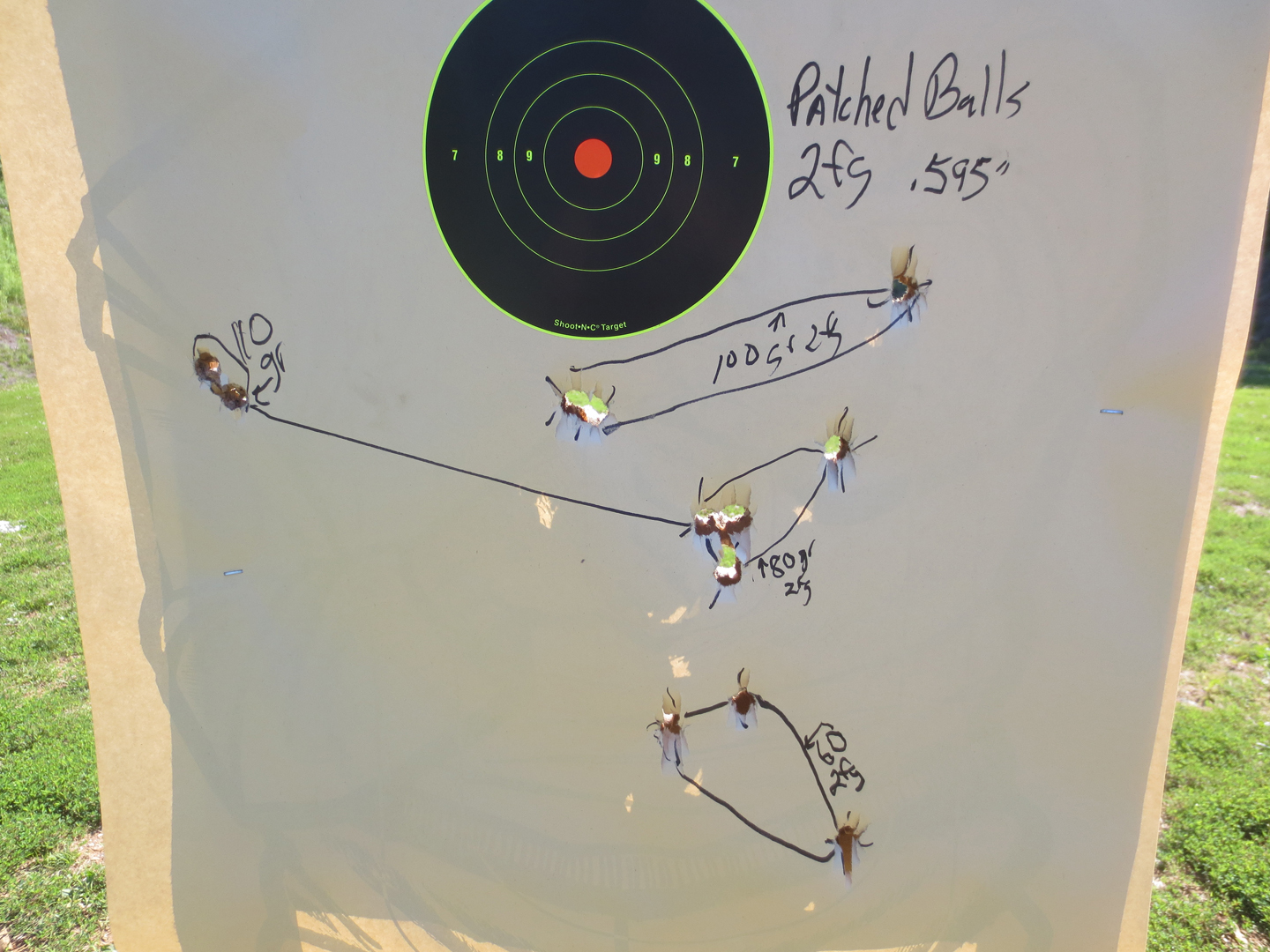

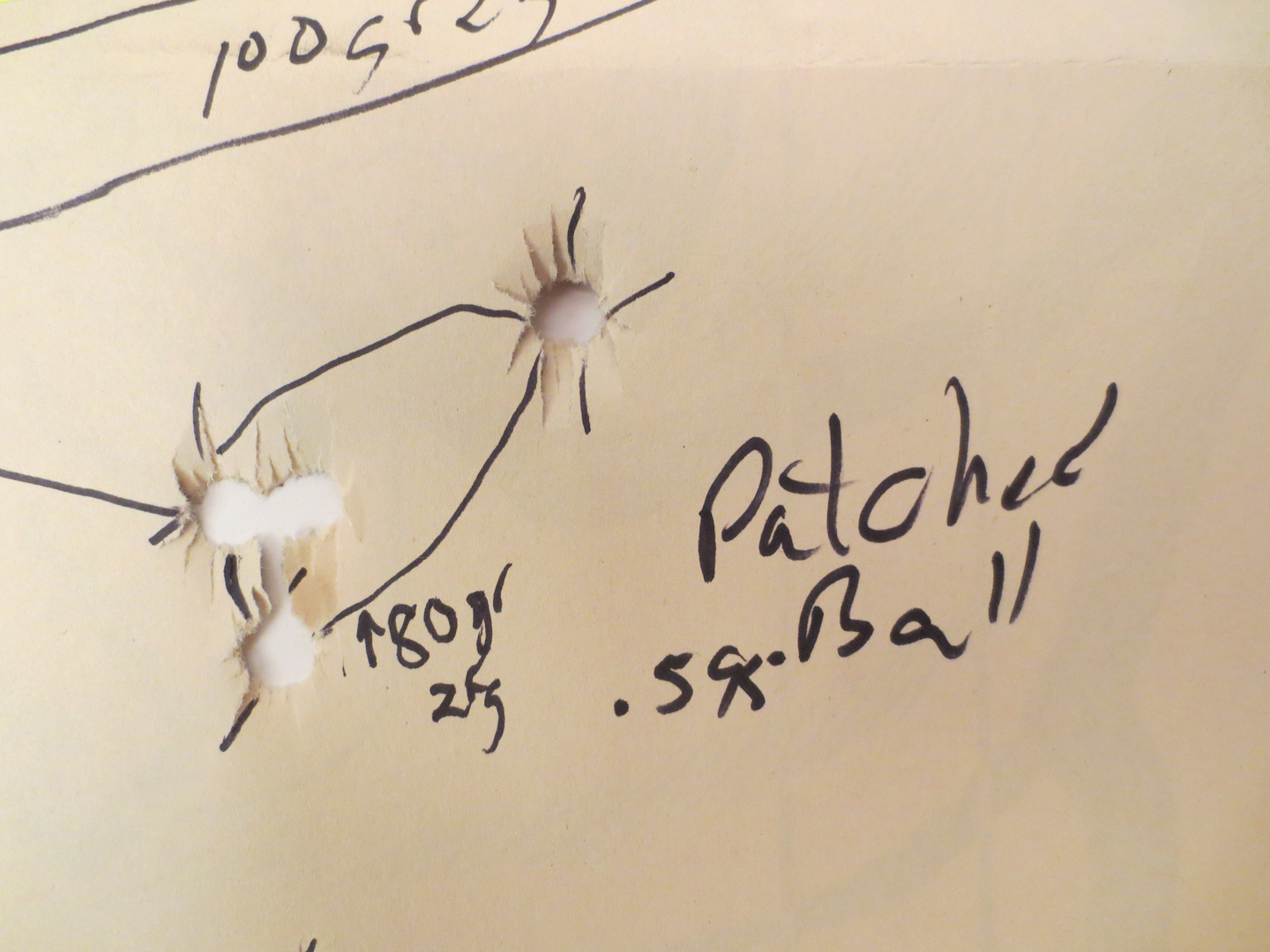

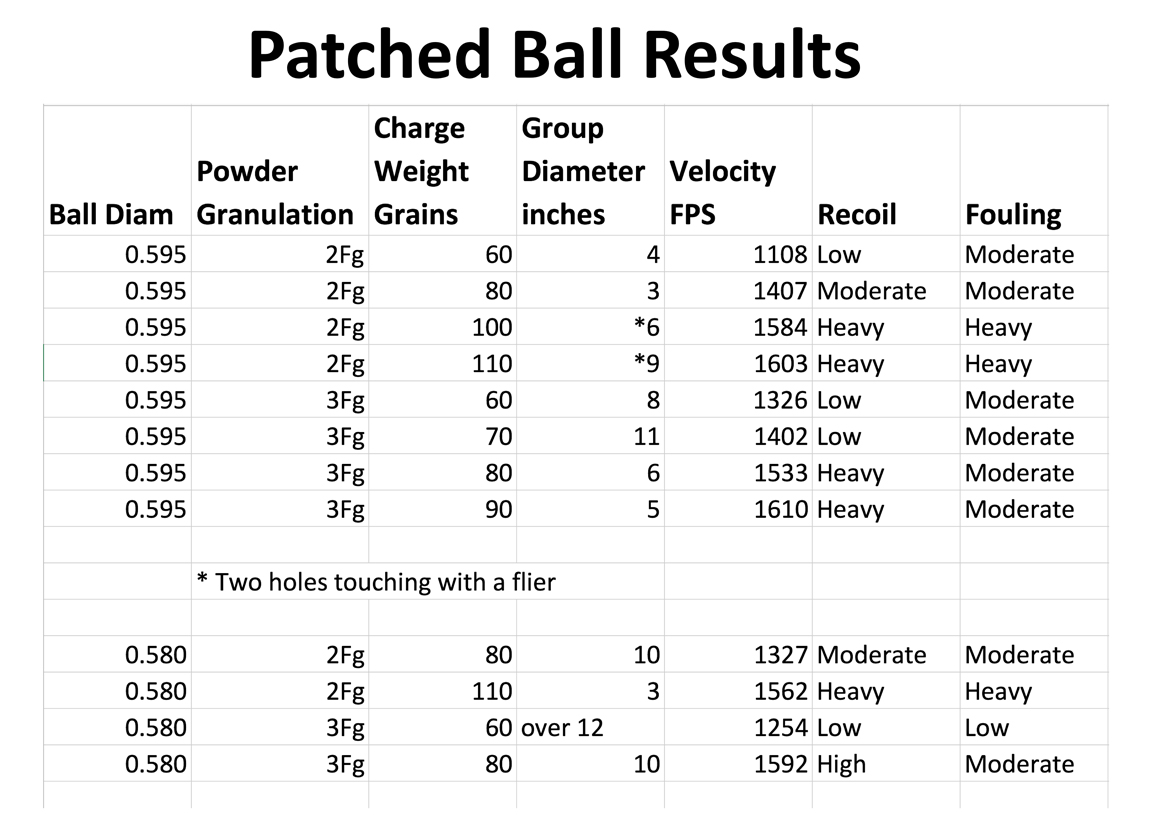

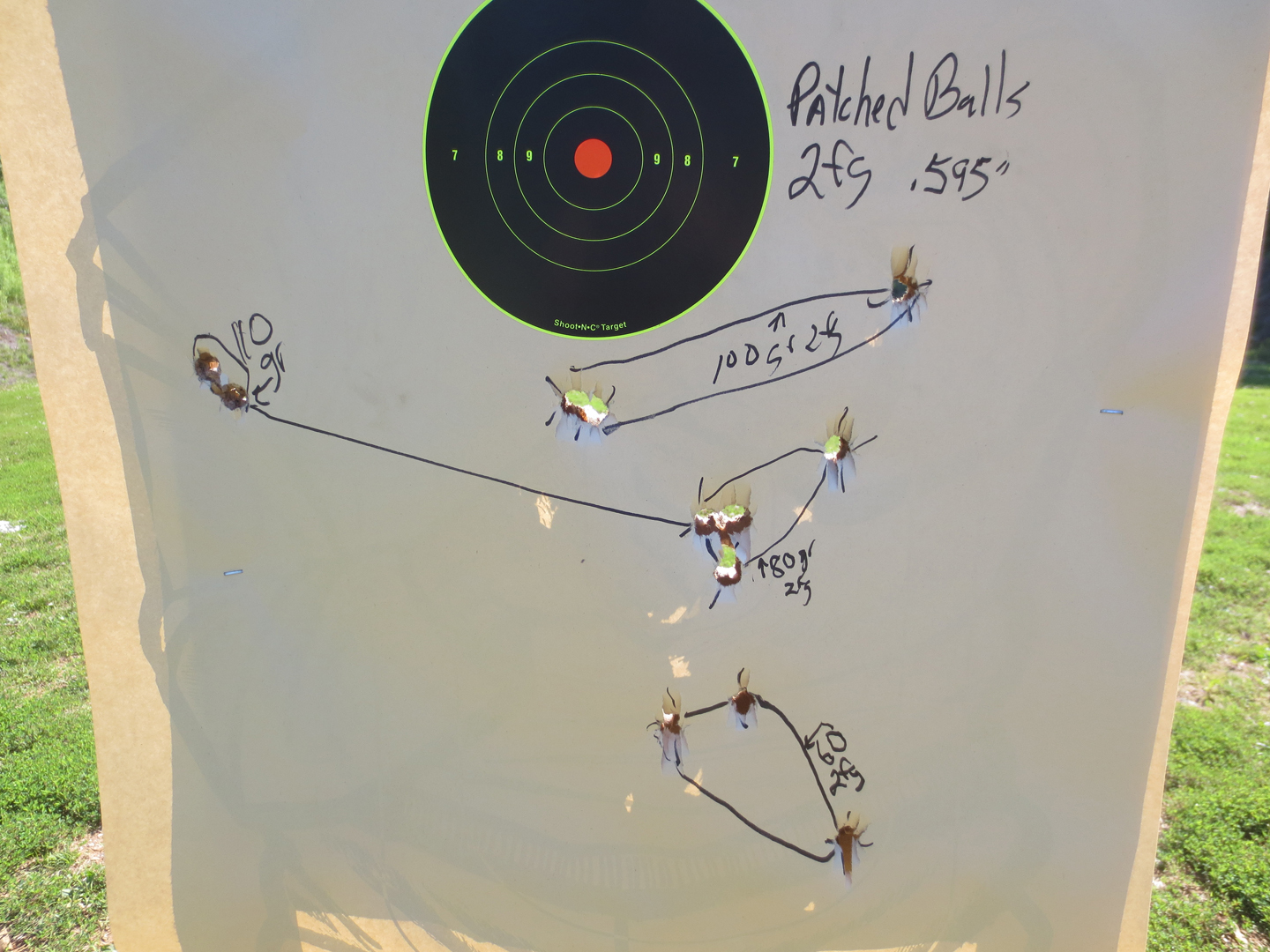

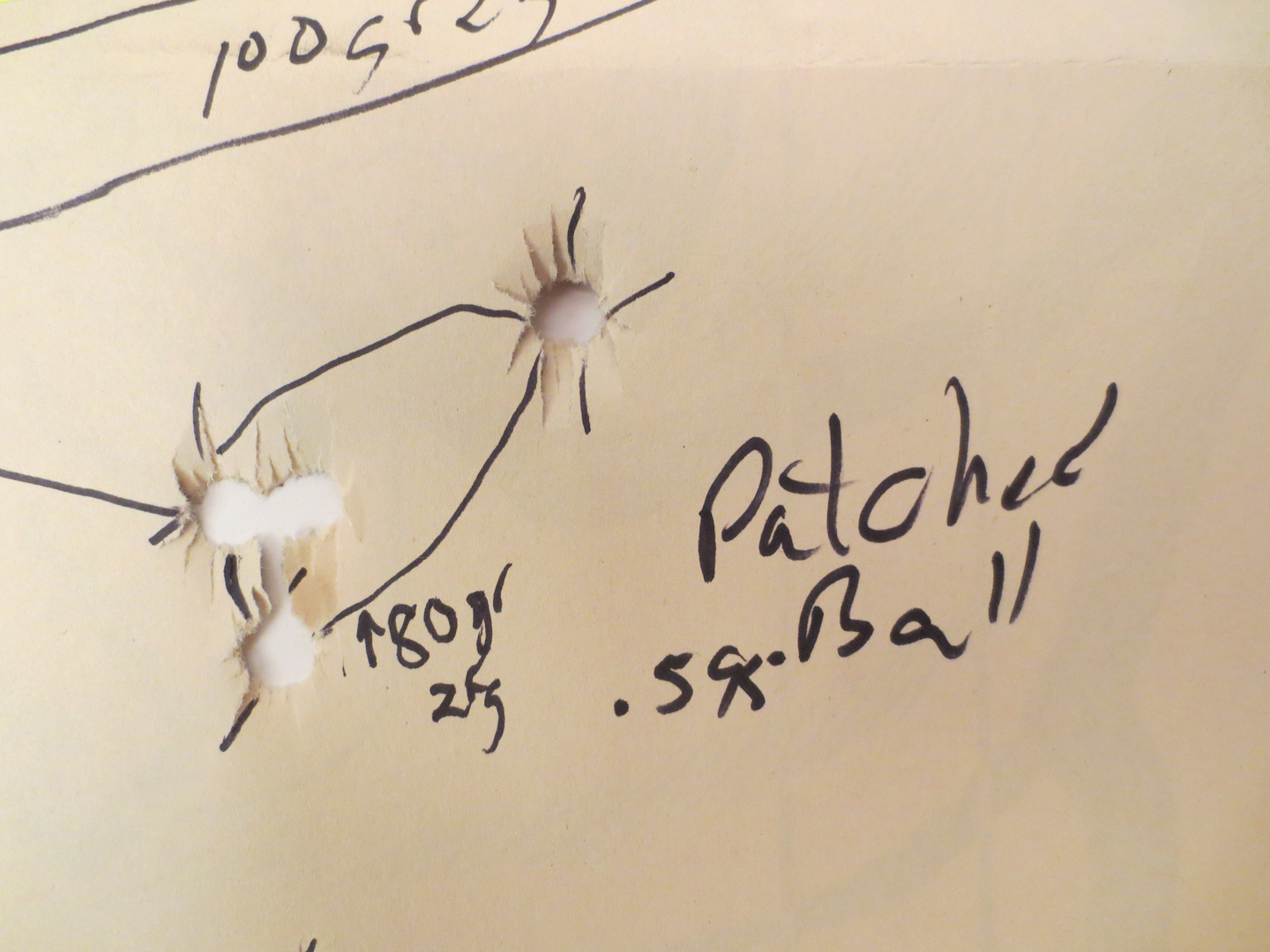

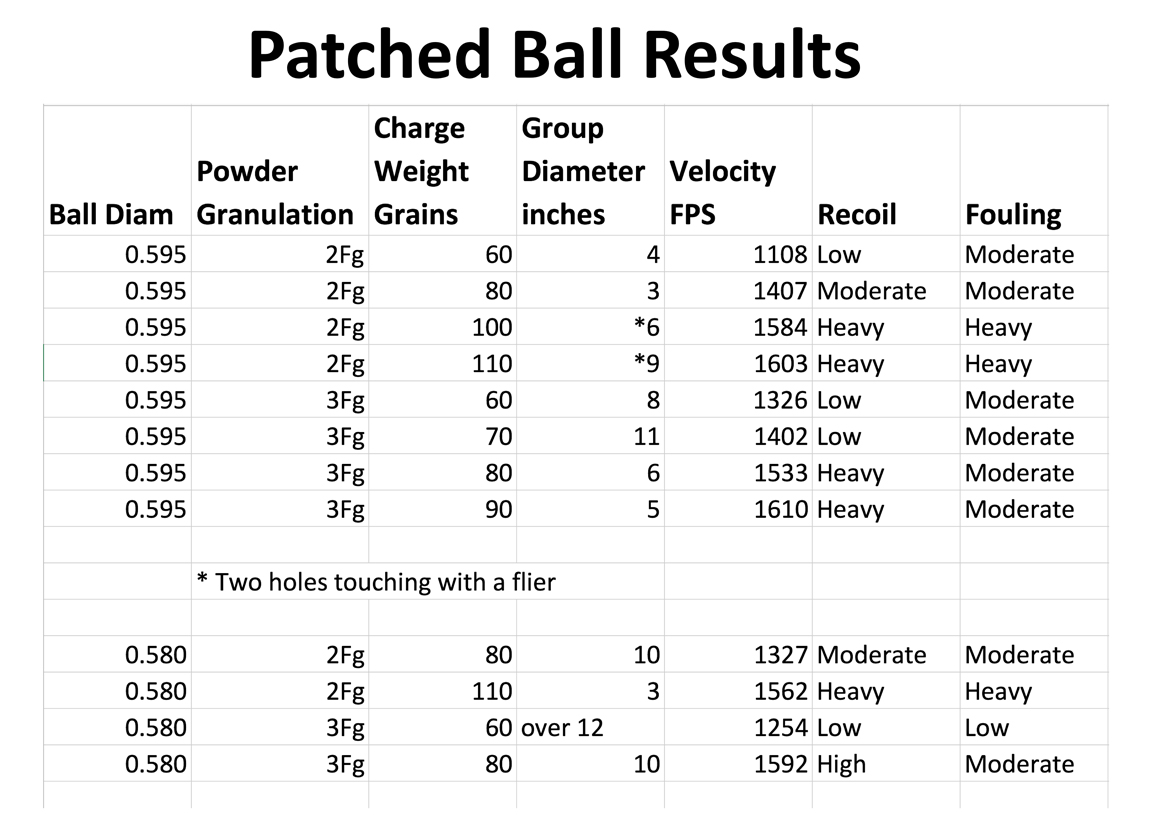

For the first round of patched ball testing I shot 0.595” balls with 0.015” patches using the most popular powder charges from the survey.

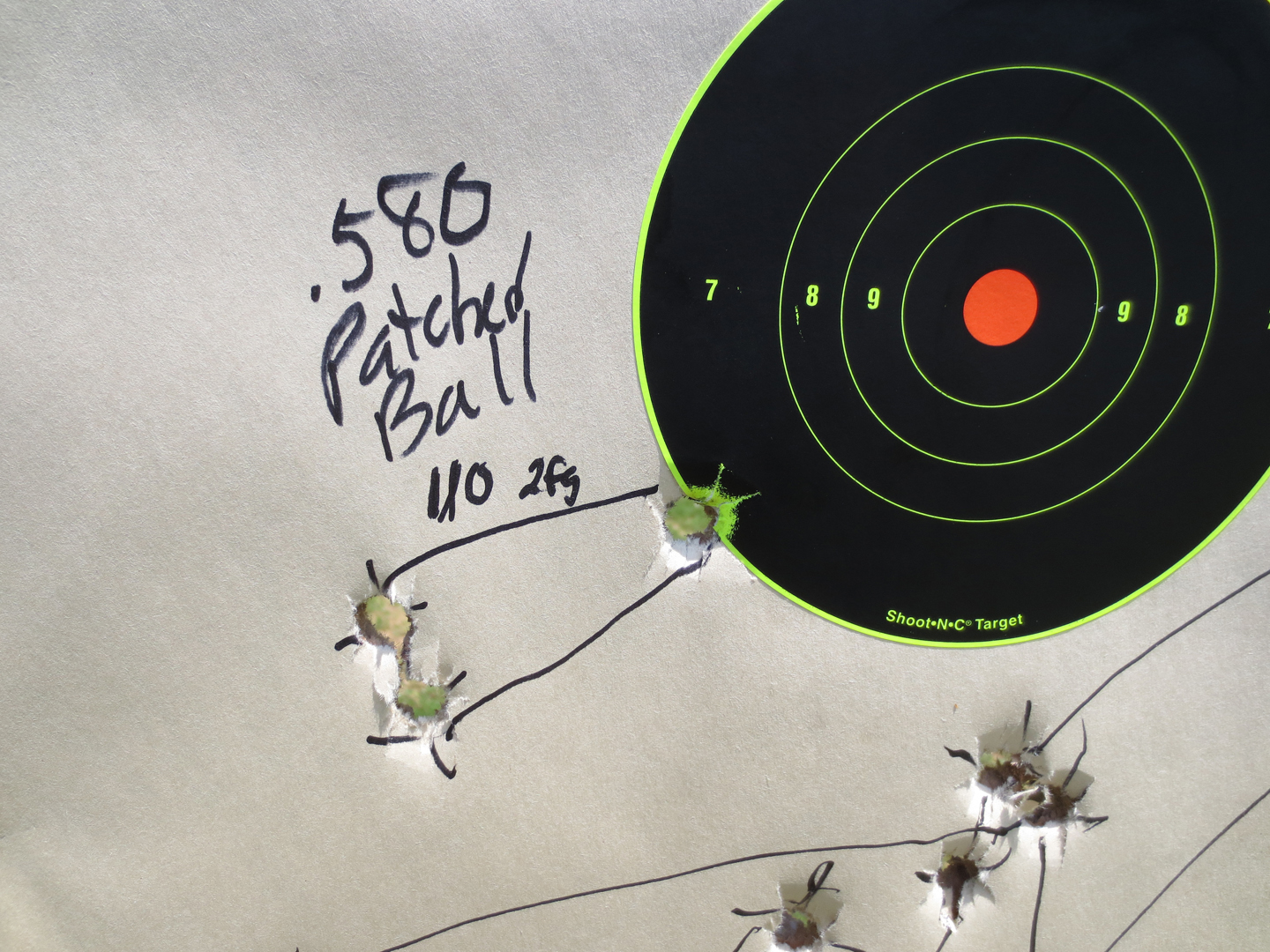

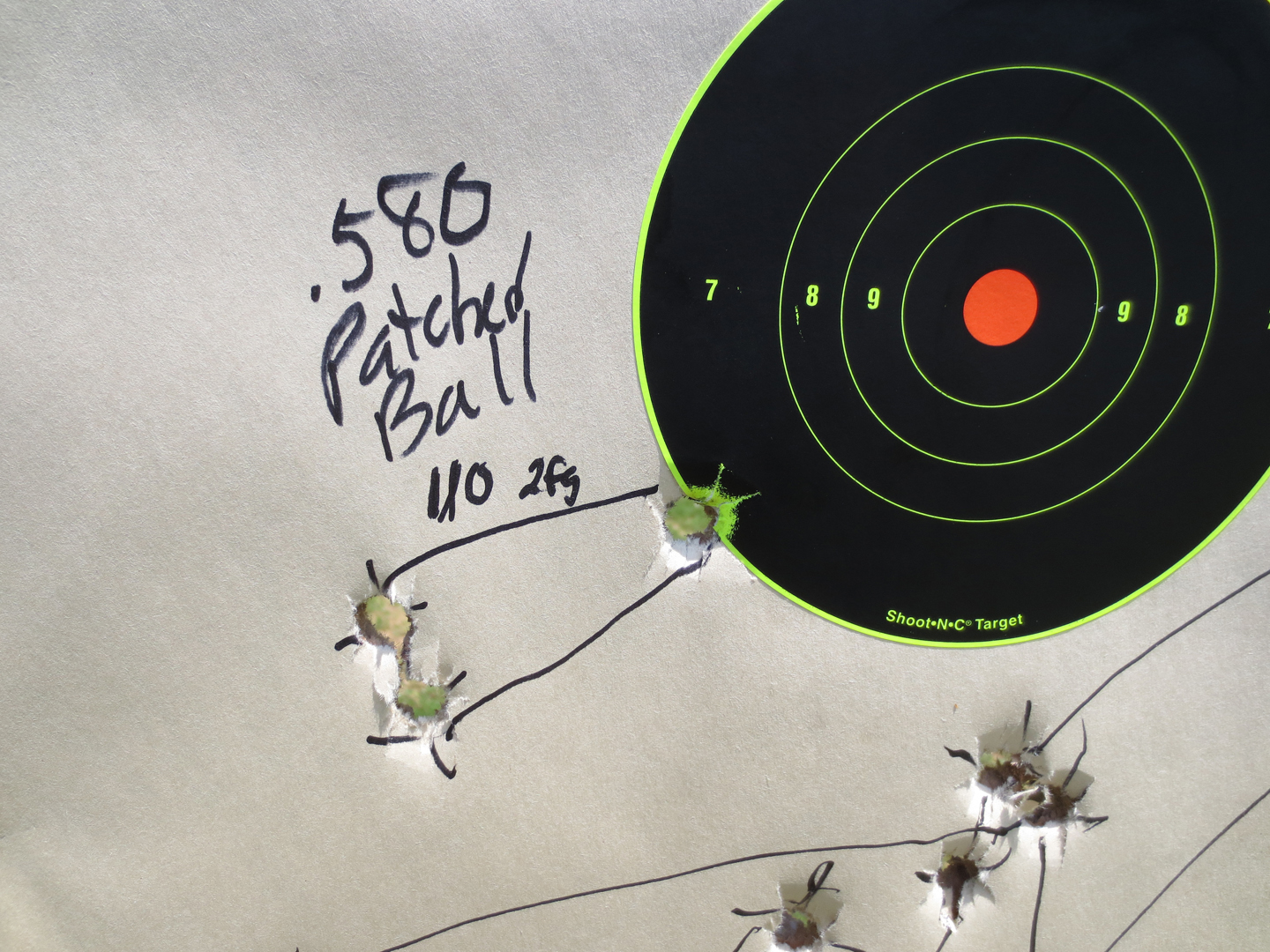

For round two, I shot 0.580” balls with the 0.015” patches, and I used the powder charges that shot the best with bare balls.

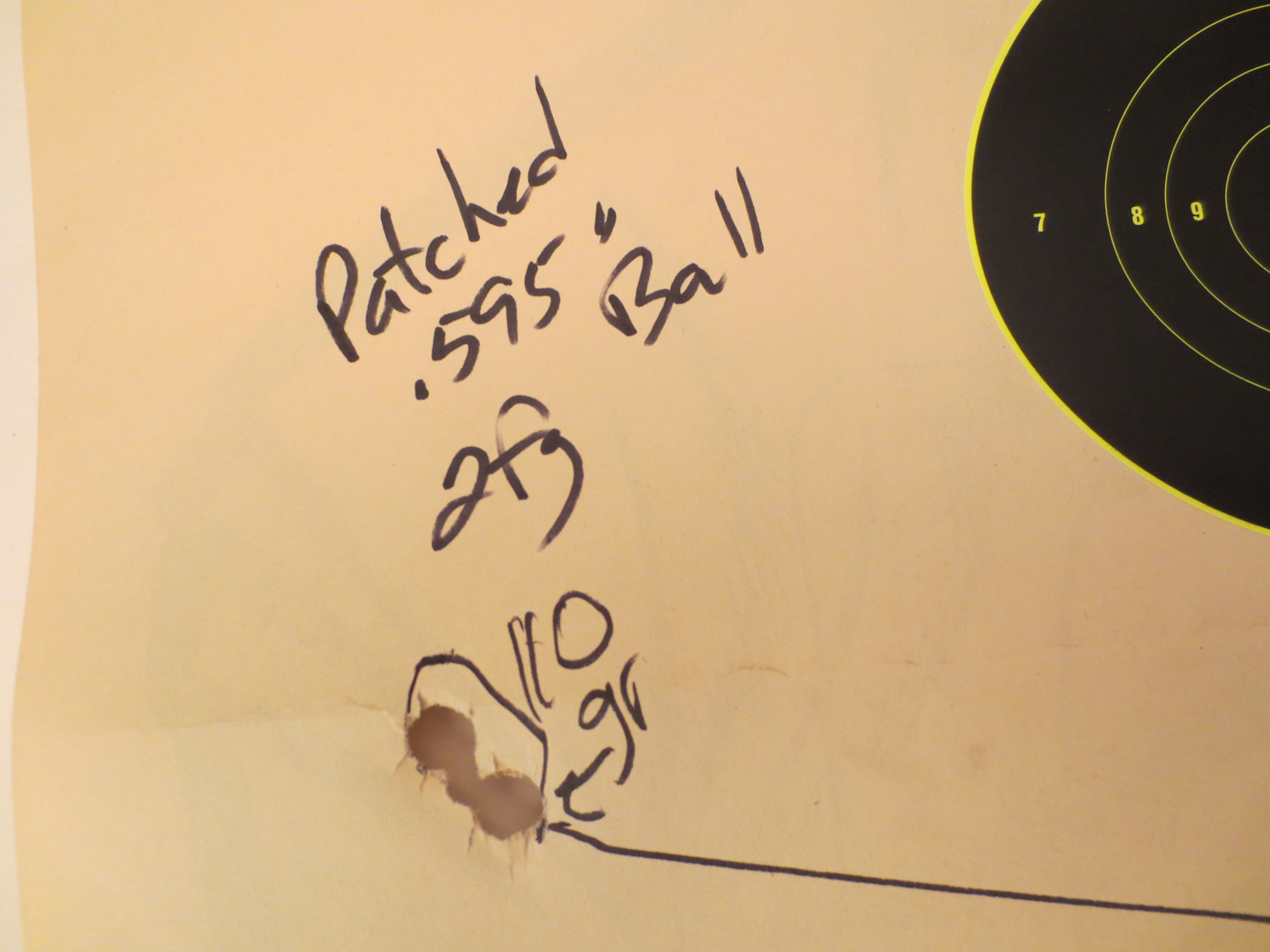

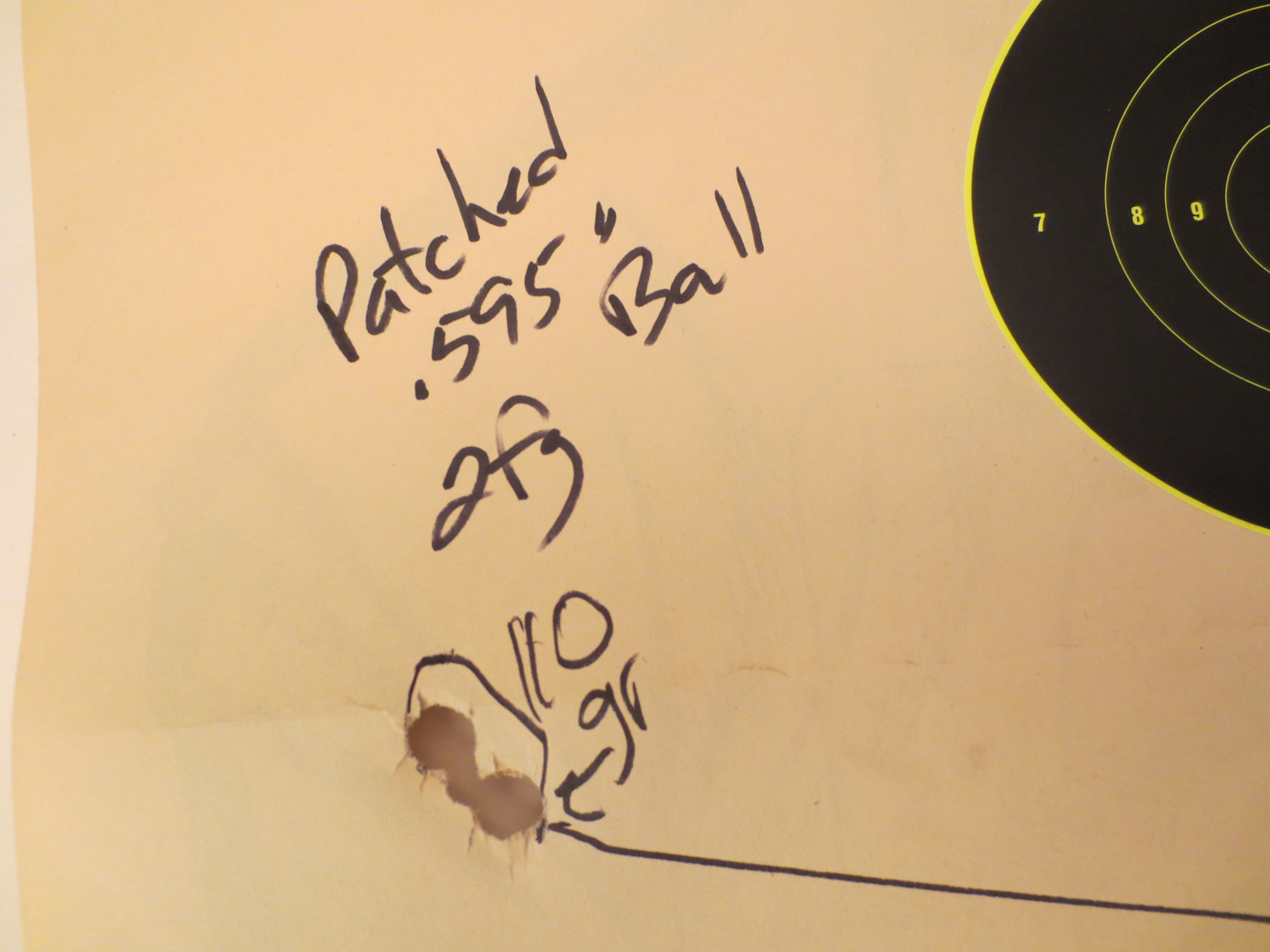

By far the best patched ball groups I shot were a 3-inch diameter with 80 grains of 2Fg/0.595” ball/0.015” patch, and another 3-inch group with 110 grains of 2Fg/0.580” ball/0.015” patch

I’m not done testing yet. I still need to shoot chewed balls, and balls wadded with modern fiber cards & wads, and I want to re-visit some results, but, I thought I’d share the preliminary findings and gather your input”¦so fire away”¦

YouTube video is here, if you prefer that format.

https://www.youtube.com/watch?v=hhTgf2OjOrs

Some of you may recall that a few months ago I took a survey here, and on some other muzzleloading sites to see how you shoot your smoothbores. For the test I shot the powder charges that came up as the most popular in my on-line survey.

I shot from the bench at 50 yards because virtually every load shoots a decent group at 25 yards, you have to get out to 50 to 100 yards before you really see what a group looks like.

I found that my results don’t always back up conventional wisdom. I suspect some of you will be getting out your scalping knives when you see my results. All I can say is that these are the results for a particular gun, and particular shooter on a particular day. Your results may vary.

So, before you unlimber your slings and arrows, I recommend you go to the range and shoot your pet load from the bench at 50 yards for a group. Then shoot my load of 110 grains of 2Fg under tow-.610 ball-tow, or 110 gr 2Fg Goex under 0.015” patch./0.580” ball, and see how your load does head to head vs mine”¦then come after me. If you do this, you’ll either feel vindicated when your load comes out on top, or you’ll have a new pet load”¦either way, you win.

So here are some take-aways:

1. The best patched ball load tested, and the best bare ball load tested, turned in exactly the same group.

2. 2Fg out-performed 3Fg with both bare balls and with patched balls

3. A tight ball/patch combo was not the most accurate shooter.

4. A looser ball/patch behaved just like a bare ball”¦liked bigger powder charges of 2Fg better than lighter charges.

5. As with bare balls, 3Fg builds pressure faster than it builds velocity with bigger loads.

For the bare ball test I shot .610-inch balls wadded with tow. My best groups were with 110 grains of 2Fg, and 80 grains of 3Fg.

For the first round of patched ball testing I shot 0.595” balls with 0.015” patches using the most popular powder charges from the survey.

For round two, I shot 0.580” balls with the 0.015” patches, and I used the powder charges that shot the best with bare balls.

By far the best patched ball groups I shot were a 3-inch diameter with 80 grains of 2Fg/0.595” ball/0.015” patch, and another 3-inch group with 110 grains of 2Fg/0.580” ball/0.015” patch

I’m not done testing yet. I still need to shoot chewed balls, and balls wadded with modern fiber cards & wads, and I want to re-visit some results, but, I thought I’d share the preliminary findings and gather your input”¦so fire away”¦

YouTube video is here, if you prefer that format.

https://www.youtube.com/watch?v=hhTgf2OjOrs

Last edited by a moderator: