I just bought a Whitneyville dragoon. Two of the nipples are stuck fast. Had them basting in hoppes oil for two days and they're still stuck. Ruined two nipple wrenches trying to get them out. Any tips?

ty

lp

ty

lp

Some folks use a thin strip of Teflon tape.when you get it out and put a new one on use high heat nickel anti seize on the threads (can be found at any auto parts store, for spark plugs) also good on breach plugs

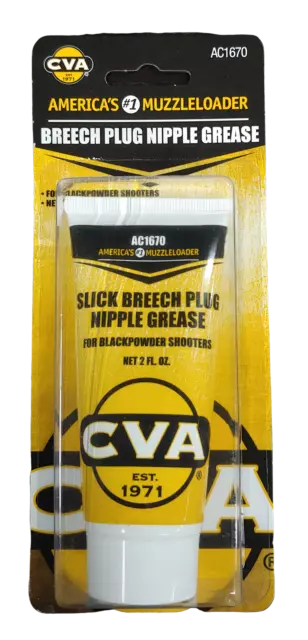

I use this. A $4 tube will last 10 lifetimes.when you get it out and put a new one on use high heat nickel anti seize on the threads (can be found at any auto parts store, for spark plugs) also good on breach plugs

Enter your email address to join: