So, I am on my first full build.... lots of questions, but this is FIRST. Where can a tang screw anchor when using double set triggers? The plate foundation that the triggers are built on has no room to drill and tap anywhere near the right place... too much going on there. Should I just use a wood screw? 45 cal, half stock, Siler small lock....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tang Screw

- Thread starter MattU

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Phil Coffins

69 Cal.

You haven’t give us much to work with, planing beforehand is often done on paper.

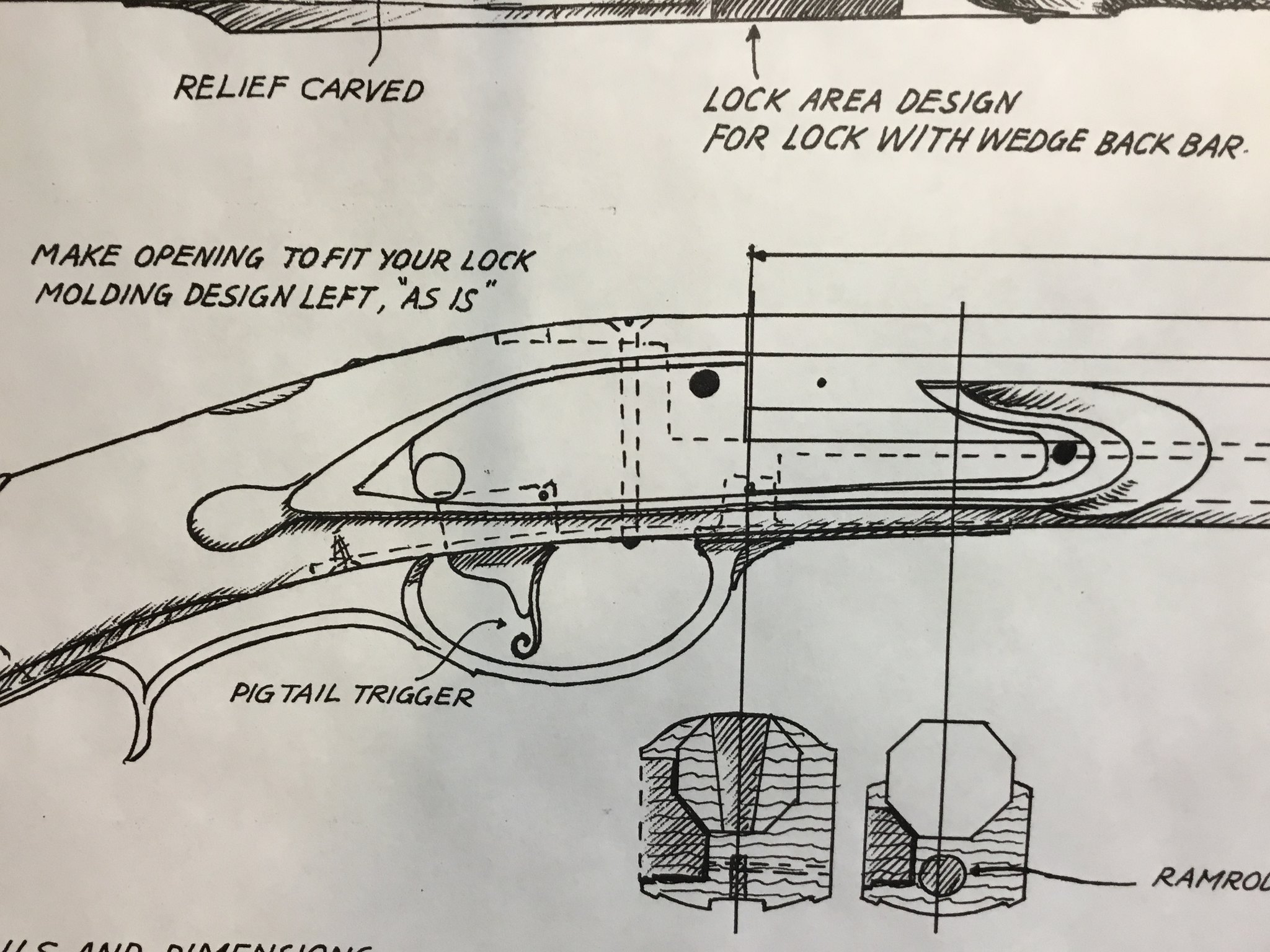

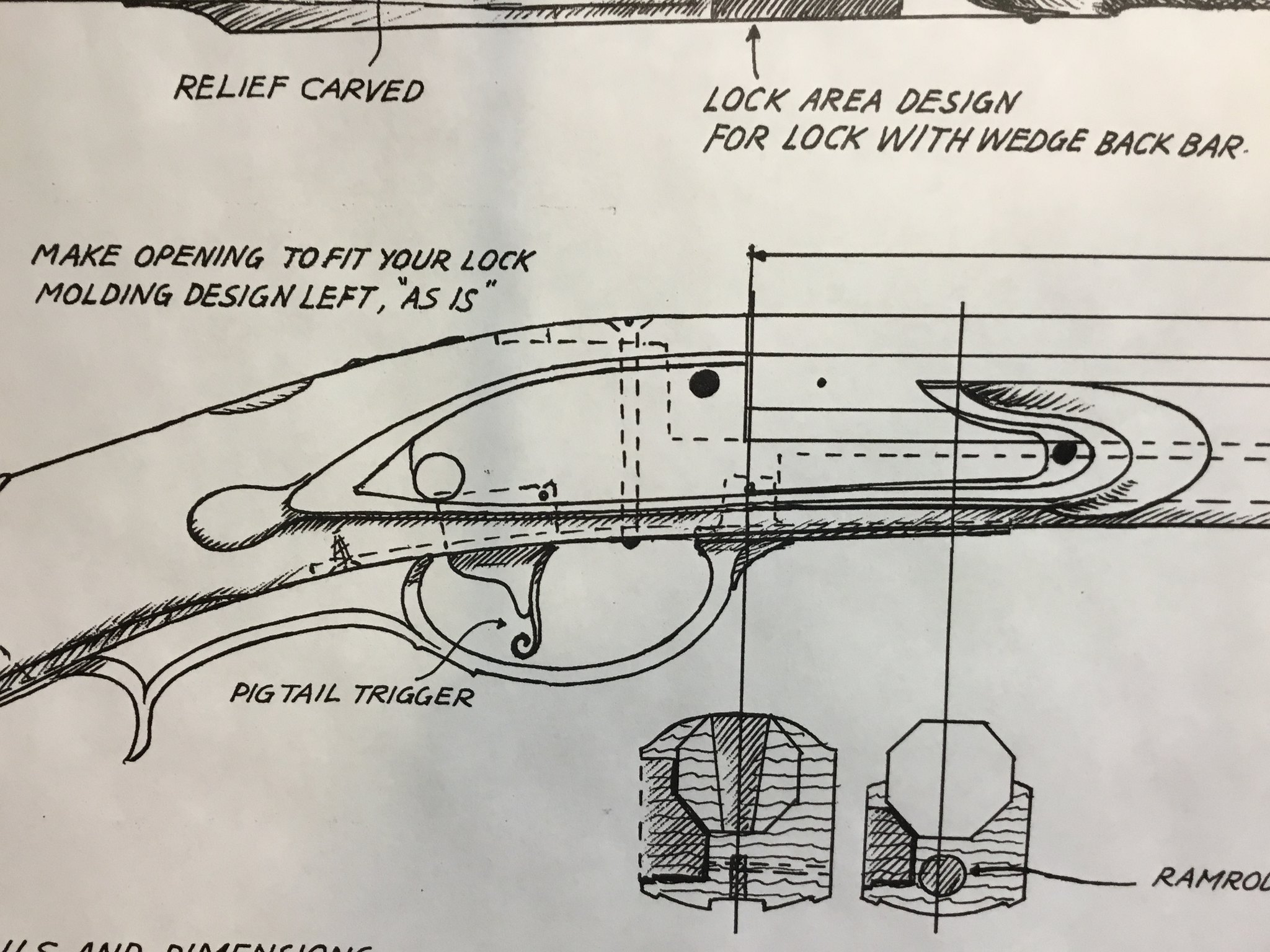

231C1032-3E4D-4ADB-847D-3234AB69EFCC by Oliver Sudden, on Flickr

231C1032-3E4D-4ADB-847D-3234AB69EFCC by Oliver Sudden, on Flickr

231C1032-3E4D-4ADB-847D-3234AB69EFCC by Oliver Sudden, on Flickr

231C1032-3E4D-4ADB-847D-3234AB69EFCC by Oliver Sudden, on FlickrGreat illustration! That would be ideal, wouldn't it! It will be a miracle if I don't hose this project with my eagerness. It is looking good so far... so there is that! The tang is a bit longer, and I assumed the screw would be at the golden ration from the back... or about a third up it... if I can put it up top, like shown here, I might just be alright! Drawings such as these leave little to the imagination!

I only held the original rifle once and traced it at that time. I wish I could have taken it apart and figured a lot of things out. I have only pictures of other rifles as reference, and each one is a bit unique.

Thanks for your thoughts.

M

I only held the original rifle once and traced it at that time. I wish I could have taken it apart and figured a lot of things out. I have only pictures of other rifles as reference, and each one is a bit unique.

Thanks for your thoughts.

M

I find a wood screw to hold the tang a poor choice, creating a weak point through the wrist of the stock. Here is what I to strengthen stocks in that area, particularly on older TCs. Later TCs replaced The forward tang wood screw with a machine screw that went through the tang, stock and trigger plate, and then threaded into the trigger guard, effectively clamping the stock between the tang and trigger guard. Older TC trigger assembles have a spring in front of the trigger that doesn’t allow this retrofit with out replacing the trigger (RE Davis Deerslayer triggers for example have the clearance hole). What I have done to many TC stocks (before any crack or after a crack repair) is to replace the two wood screws in the tang with machine screws and threaded inserts in the trigger mortise, similar to what Lyman does on their GPR. Knock on wood, but have not had one crack or re-crack after this reinforcement has been made. Here are a few photographs to help explain.So, I am on my first full build.... lots of questions, but this is FIRST. Where can a tang screw anchor when using double set triggers? The plate foundation that the triggers are built on has no room to drill and tap anywhere near the right place... too much going on there. Should I just use a wood screw? 45 cal, half stock, Siler small lock....

Sidney Smith

58 Cal.

- Joined

- Feb 17, 2019

- Messages

- 2,205

- Reaction score

- 2,312

The best method is to drill into the trigger plate, and thread the plate to accept the tang bolt. Now a wood screw can and has been used, even though it's not the most secure method. I have a TVM Lancaster that I built from a kit, and the half assed directions that came with the kit(old kit from the 90s) mentioned using an included wood screw for the tang.

- Joined

- Nov 26, 2005

- Messages

- 5,230

- Reaction score

- 10,924

Hi,So, I am on my first full build.... lots of questions, but this is FIRST. Where can a tang screw anchor when using double set triggers? The plate foundation that the triggers are built on has no room to drill and tap anywhere near the right place... too much going on there. Should I just use a wood screw? 45 cal, half stock, Siler small lock....

Your set triggers have no room for a tang bolt? What triggers are you using?

dave

Not sure on the trigger brand - I have had them for well over 25 years. The springs take up a good portion of the frame holding the triggers. I am waiting for my lock to come UPS from track of the wolf, so after inletting it, maybe life will be more clear? Maybe?

Col. Batguano

75 Cal.

- Joined

- Feb 10, 2011

- Messages

- 5,039

- Reaction score

- 1,424

The lock bolt in the drawing is placed too far forward. Do you see how the bolt head is somewhat lopsided / filed down in the rear? That maybe works for tang bolts that are flat heads, AND always tightened to the same spot, but NOT for the oval headed tang bolts that most of us use most of the time. You want the tang bolt head to be at a right angle tangent to the curve of the wrist, and intersecting the trigger plate at your desired location.

So to get that perfect spot, wait until the top of your wrist shape is pretty much 95%+ formed. Then make yourself a right angle gauge that will let you find the location. If you get it too far fore or aft, you will wind up with a bolt head that is proud to the tang on the opposite side.

Another thing to be careful of in drilling your tang bolt hole is drill bit "walking". Use scratch awls (making and "X" with them) and a punch to find the spot. Then drill a very small hole (like 1/16") followed by reaming it out to a bigger one (1/8"), and then maybe one more before your final diameter. And take your time.

It's easy to get this hole misplaced / mis-drilled, and with the thin margins on the sides of the bolt head that misalignment right in front of your nose will always bug you.

So to get that perfect spot, wait until the top of your wrist shape is pretty much 95%+ formed. Then make yourself a right angle gauge that will let you find the location. If you get it too far fore or aft, you will wind up with a bolt head that is proud to the tang on the opposite side.

Another thing to be careful of in drilling your tang bolt hole is drill bit "walking". Use scratch awls (making and "X" with them) and a punch to find the spot. Then drill a very small hole (like 1/16") followed by reaming it out to a bigger one (1/8"), and then maybe one more before your final diameter. And take your time.

It's easy to get this hole misplaced / mis-drilled, and with the thin margins on the sides of the bolt head that misalignment right in front of your nose will always bug you.

Last edited:

Buckskinn

45 Cal.

And I thought I was a procrastinator! A picture is in order me thinks... You could always get a new Davis for about $45.

Lots of good advise above. The only thing I can add is to use good quality drills and the shorter the better to start the hole. Long drills can wander off. I like to use a center drill to start the hole. Just don't use Harbor Freight quality Chinese drills for a critical hole. If you have a way to line up the hole top to bottom, like an accurate line drawn on the stock, it helps to drill from both top and bottom of the stock with the holes meeting somewhere near the middle. You can then clean up the hole with the next larger drill.

- Joined

- Aug 27, 2004

- Messages

- 3,240

- Reaction score

- 7,178

If you could post a photo of the triggers, we can help better.Not sure on the trigger brand - I have had them for well over 25 years. The springs take up a good portion of the frame holding the triggers. I am waiting for my lock to come UPS from track of the wolf, so after inletting it, maybe life will be more clear? Maybe?

Larry

user 34300

54 Cal.

- Joined

- Nov 25, 2019

- Messages

- 1,743

- Reaction score

- 2,124

So, I am on my first full build.... lots of questions, but this is FIRST. Where can a tang screw anchor when using double set triggers? The plate foundation that the triggers are built on has no room to drill and tap anywhere near the right place... too much going on there. Should I just use a wood screw? 45 cal, half stock, Siler small lock....

Yeah is does. It will work. You need to draw everything on the side of the stock in minute detail before you cut anything. I normally glue some quality paper to the side of the wood for ease of drawing and erasing. Once you have all the parts laid out on the paper you can cut wood with no guessing.

This guy goes through the process:

The plate foundation that the triggers are built on has no room to drill and tap anywhere near the right place... too much going on there.

Have you inlet the trigger? I always do that after the lock is inlet to make sure the trigger and lock function correctly together. How have you determined there is no room on the trigger plate for a tapped hole?Not sure on the trigger brand - I have had them for well over 25 years. The springs take up a good portion of the frame holding the triggers. I am waiting for my lock to come UPS from track of the wolf, so after inletting it, maybe life will be more clear? Maybe?

As others have suggested, there should be room on the trigger plate, if not, may be best to get a new trigger, as this is a new build (correct?), and you want to get it right. Others have asked, but I’ll ask again, could you please post a photograph of your trigger? It is unlikely that it is so unique that no one here has not seen or used it or a similar one. Below is a photograph of three triggers on my workbench. Does your trigger look like one of those? The two on top are intended for TCs and there is no practical place to drill and tap in to the trigger plate. The one in the middle has a clearance hole in it to allow the tang screw to go through it and thread into the trigger guard. The trigger on the bottom is new and never install or fit in a gun. It has a trigger plate similar to what you should have. Plenty of room for a threaded hole and extra length to so it can be trimmed to whatever length works or you desire.

cajun

36 Cl.

- Joined

- Apr 18, 2020

- Messages

- 75

- Reaction score

- 26

Sir, where do you get those threaded inserts from and what size are they. ThanksI find a wood screw to hold the tang a poor choice, creating a weak point through the wrist of the stock. Here is what I to strengthen stocks in that area, particularly on older TCs. Later TCs replaced The forward tang wood screw with a machine screw that went through the tang, stock and trigger plate, and then threaded into the trigger guard, effectively clamping the stock between the tang and trigger guard. Older TC trigger assembles have a spring in front of the trigger that doesn’t allow this retrofit with out replacing the trigger (RE Davis Deerslayer triggers for example have the clearance hole). What I have done to many TC stocks (before any crack or after a crack repair) is to replace the two wood screws in the tang with machine screws and threaded inserts in the trigger mortise, similar to what Lyman does on their GPR. Knock on wood, but have not had one crack or re-crack after this reinforcement has been made. Here are a few photographs to help explain.

View attachment 115944View attachment 115945View attachment 115946View attachment 115947

I have purchased from MSC, and have seen ‘variety’ packs at Harbor Freight, though not for some time. For size, get the size to match the tang screw your want to use. I use more with 10-32 threads than any other for tang inserts.Sir, where do you get those threaded inserts from and what size are they. Thanks

cajun

36 Cl.

- Joined

- Apr 18, 2020

- Messages

- 75

- Reaction score

- 26

Thank you, Sir!!!I have purchased from MSC, and have seen ‘variety’ packs at Harbor Freight, though not for some time. For size, get the size to match the tang screw your want to use. I use more with 10-32 threads than any other for tang inserts.

View attachment 116256

Lowes carries the brass thread inserts (they work in plastic too).

- Joined

- Jun 12, 2005

- Messages

- 8,017

- Reaction score

- 1,023

although a bit pricey, you may want to consider the purchase of The Gunsmith of Grenvill County by Peter Alexander. It's available from Track of The Wolf ... here's a link

The Gunsmith of Grenville County, Building the American Longrifle illustrated instruction manual, revised edition, spiral bound, by Peter A. Alexander - Track of the Wolf

this will set you back about fifty bucks after tax, shipping and so on, but i've had my copy through several builds, and i can state with confidence that it's more than saved me the purchase price in parts i didn't ruin (as well as time i didn't waste waiting for the replacement parts, and time i won't have to spend in purgatory due to bad language i didn't use).

best of luck!

(the coolest tools are the ones you make for yourself)

The Gunsmith of Grenville County, Building the American Longrifle illustrated instruction manual, revised edition, spiral bound, by Peter A. Alexander - Track of the Wolf

this will set you back about fifty bucks after tax, shipping and so on, but i've had my copy through several builds, and i can state with confidence that it's more than saved me the purchase price in parts i didn't ruin (as well as time i didn't waste waiting for the replacement parts, and time i won't have to spend in purgatory due to bad language i didn't use).

best of luck!

(the coolest tools are the ones you make for yourself)

illinois old fart

32 Cal

What type of head do you use on the 10/32 screws.Have you inlet the trigger? I always do that after the lock is inlet to make sure the trigger and lock function correctly together. How have you determined there is no room on the trigger plate for a tapped hole?

As others have suggested, there should be room on the trigger plate, if not, may be best to get a new trigger, as this is a new build (correct?), and you want to get it right. Others have asked, but I’ll ask again, could you please post a photograph of your trigger? It is unlikely that it is so unique that no one here has not seen or used it or a similar one. Below is a photograph of three triggers on my workbench. Does your trigger look like one of those? The two on top are intended for TCs and there is no practical place to drill and tap in to the trigger plate. The one in the middle has a clearance hole in it to allow the tang screw to go through it and thread into the trigger guard. The trigger on the bottom is new and never install or fit in a gun. It has a trigger plate similar to what you should have. Plenty of room for a threaded hole and extra length to so it can be trimmed to whatever length works or you desire.

View attachment 116122

Similar threads

- Replies

- 19

- Views

- 2K