Hi Dave, When you deliver a rifle to a customer have you tuned the lock or do you deliver it the way it came out of the box? With all the problems one must encounter still present?

If you do tune the lock do you go the long way and incorporate the neat tricks and fixes you have figured out over the years.

Across the board of gunbuilders today do most of them tune or at least polish inside the lock before handing it over?

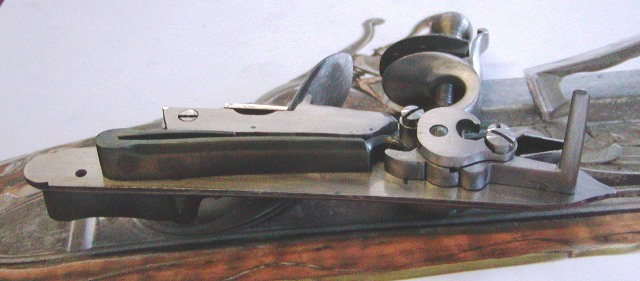

I personally feel the gun should be balanced and the lock tight and slick when cocked. Even if it takes extra time to do so?

I personally feel the gun should be as right as possible when finished and that includes a smooth trigger pull and a basic well tuned lock. And I don't consider a rifle finished until it is turn key and ready to shoot.

I might have it all wrong and if so that is what I'm trying to determine.

Thanks, Darkhorse

If you do tune the lock do you go the long way and incorporate the neat tricks and fixes you have figured out over the years.

Across the board of gunbuilders today do most of them tune or at least polish inside the lock before handing it over?

I personally feel the gun should be balanced and the lock tight and slick when cocked. Even if it takes extra time to do so?

I personally feel the gun should be as right as possible when finished and that includes a smooth trigger pull and a basic well tuned lock. And I don't consider a rifle finished until it is turn key and ready to shoot.

I might have it all wrong and if so that is what I'm trying to determine.

Thanks, Darkhorse