I recently purchased a prior owned 12 ga trade gun. It is in the white for its entire lengthy existence. I was thinking, so I briefly researched, one article I read, the writer stated that a large number if not most Trade Guns, came "blued". Would that mean some sort of external barrel treatment or would they have been in the white.?????

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trade Gun

- Thread starter blackhorse

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It could be either blued or in the white. In the white, if the manufacturer was keeping the cost low. Blued if this was a higher grade chief's gun or in the white to a higher polish.

I guess my question should have been white, blued or "browned" ??? I don't know that I have ever seen a ML firearm in the "blue"..

Buck Conner

40 Cal

.

I spent years hanging out with the most knowledgeable person on this subject "Trade Guns". Charles E. Hanson, Jr. has forgotten more about these guns than we will ever know. Charley had found (51) manufacturers that producted 200 or more guns a year (most from London with their "cottage industry" style of production).

I was in the process of researching these numbers of manufacturers and found (using his guide-lines) a few more than Charley had found when his North West Trade book was written. In early 2000 I had 124 manufacturers that fit his "200 or more guns a year" guyide lines. I would show what I found with my research and he would double check what I had, a few were left off my list for one reason or another. Finally after several years we were ready to publish my book, had 500 printed to start with. Next thing I know it is listed in the US Library of Congress (shown as a must have research book on the North West Trade Gun). After the second printing of 500 sales started to slow down, the next printing of 500 finally sold. Now I'm getting request for the book again and am thinking about working with Amazon to make it available through their system and Kindle's program.

The best part of assembling this information was the time spent with Charley and Marie in Chadron NE.

PUBLISHED 2005

If we go with one of these firms I have a few things that need to be changed (correct information that has changed with future research).

I just saw a copy of this book on Amazon for double the original retail cost - now asking $49.99

.

I spent years hanging out with the most knowledgeable person on this subject "Trade Guns". Charles E. Hanson, Jr. has forgotten more about these guns than we will ever know. Charley had found (51) manufacturers that producted 200 or more guns a year (most from London with their "cottage industry" style of production).

* We think of the term "cottage industry" as a hippy thing from the 1950's or 60's, when this type of work has been around for a century or more.

I was in the process of researching these numbers of manufacturers and found (using his guide-lines) a few more than Charley had found when his North West Trade book was written. In early 2000 I had 124 manufacturers that fit his "200 or more guns a year" guyide lines. I would show what I found with my research and he would double check what I had, a few were left off my list for one reason or another. Finally after several years we were ready to publish my book, had 500 printed to start with. Next thing I know it is listed in the US Library of Congress (shown as a must have research book on the North West Trade Gun). After the second printing of 500 sales started to slow down, the next printing of 500 finally sold. Now I'm getting request for the book again and am thinking about working with Amazon to make it available through their system and Kindle's program.

The best part of assembling this information was the time spent with Charley and Marie in Chadron NE.

PUBLISHED 2005

I just saw a copy of this book on Amazon for double the original retail cost - now asking $49.99

WOW

.

Buck Conner

40 Cal

I guess my question should have been white, blued or "browned" ??? I don't know that I have ever seen a ML firearm in the "blue"..

You will see different replies to you question on the finish for your tradegun. You have several answers to your question stated. "white", "blued" or "browned". It would depend on what the government contract ask for. In many contracts you'll find "white" for all the metal parts (trigger guard, lock, barrel and so on with screws, etc.). Then another contract you'll find "blue" for all the metal parts (trigger guard, lock, barrel and so on with screws, etc.). Usually "browned" was the result of a gun "in-the-white" rusting to a brown color.

.

It also depends the time as well.

For example the French fusils were usually in the white, mimicking the military muskets that they were produced alongside.

For example the French fusils were usually in the white, mimicking the military muskets that they were produced alongside.

Blue was common on ml guns in the past. Over the years many of these guns browned as the finish oxidized to a brown. Since brown is the color of antique guns we assumed they started out brown, and a blue barrel looks wrong.I guess my question should have been white, blued or "browned" ??? I don't know that I have ever seen a ML firearm in the "blue"..

Blueing, rust or fire was expensive so trade guns got much less expensive versions, or in the white.

true browning became popular in the nineteenth century

Many original Hawkens started off with a rust blued finish. They also mostly had straight grain, strong and plainly finished maple wood stocks that were rarely highly figured.

The term "trade gun" can cover a wide field. There were French fusils, British "Carolina guns," and Northwest guns, originally from England but later from Belgium and the United States. Not to mention Dutch and German trade guns, and Lord only knows what else. However, I'm going to make a leap of faith and assume we're talking about Northwest guns.

I was reviewing some of my references just recently. I think most of the early Northwest guns were blued, but some of the later ones were requested to be browned. In fact, one order I saw recently, if I remember correctly, specified "half to be blued, and the others brown." I'll go back and try to confirm that.

Indians, who were the primary end-users of these guns, were said to have preferred a "bright, clear blue" on the barrel. So, in answer to your question, I believe these guns would have been intentionally blued or browned by the builder prior to selling them.

Moving on to one other point of interest in the original post, the only person I know of who made 12 gauge trade guns was Curly Gostomski. There may have been others, but Curly (the founder of North Star West) was the only one I know of. I believe that after North Star West changed hands and was taken over by Matt Denison, they made a very few trade guns in 16 gauge, but no twelves that I know of. Anyway, if you have one of Curly's guns, please bear in mind that they are collectors items in their own right, nowadays. I don't think it will hurt it to shoot it, particularly if it was shot by previous owners, and the natural coloration or "patina" that it will continue to acquire with time and handling will add to its character. However, if it were mine, I would not try to refinish either the wood or metal.

It would be great if you could post some pictures of the gun you have... Full-length images of both sides and a close-up of the breech area, showing the entire lock, trigger, trigger-guard bow, and breech.

Thanks for posting! I'll look forward to learning some more about this.

Best regards,

Notchy Bob

I was reviewing some of my references just recently. I think most of the early Northwest guns were blued, but some of the later ones were requested to be browned. In fact, one order I saw recently, if I remember correctly, specified "half to be blued, and the others brown." I'll go back and try to confirm that.

Indians, who were the primary end-users of these guns, were said to have preferred a "bright, clear blue" on the barrel. So, in answer to your question, I believe these guns would have been intentionally blued or browned by the builder prior to selling them.

Moving on to one other point of interest in the original post, the only person I know of who made 12 gauge trade guns was Curly Gostomski. There may have been others, but Curly (the founder of North Star West) was the only one I know of. I believe that after North Star West changed hands and was taken over by Matt Denison, they made a very few trade guns in 16 gauge, but no twelves that I know of. Anyway, if you have one of Curly's guns, please bear in mind that they are collectors items in their own right, nowadays. I don't think it will hurt it to shoot it, particularly if it was shot by previous owners, and the natural coloration or "patina" that it will continue to acquire with time and handling will add to its character. However, if it were mine, I would not try to refinish either the wood or metal.

It would be great if you could post some pictures of the gun you have... Full-length images of both sides and a close-up of the breech area, showing the entire lock, trigger, trigger-guard bow, and breech.

Thanks for posting! I'll look forward to learning some more about this.

Best regards,

Notchy Bob

Golden age arms also made a 12 gage, on a NWG platform back in the late seventies.

In their add they said the barrel was designed for shot and not ball. I was about to get one but found a sawn off Brown Bess instead.

In their add they said the barrel was designed for shot and not ball. I was about to get one but found a sawn off Brown Bess instead.

The guy I bought it from thought it may be a Gostomski but he could not verify that ... I will post pics after I put it back together, I am inspecting and cleaning as I just got it.

- Joined

- Nov 26, 2005

- Messages

- 5,221

- Reaction score

- 10,877

Hi,

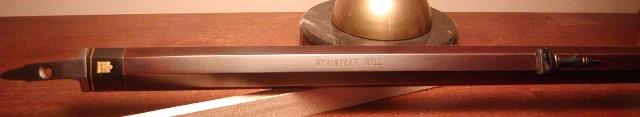

During the first half of the 18th century barrels and iron /steel hardware were temper/fire/ blued, charcoal blued, painted with asphaltum (russetted), or left bright. Below are examples of each treatment. First, left bright. Polished iron (not steel) is amazingly resistant to rust:

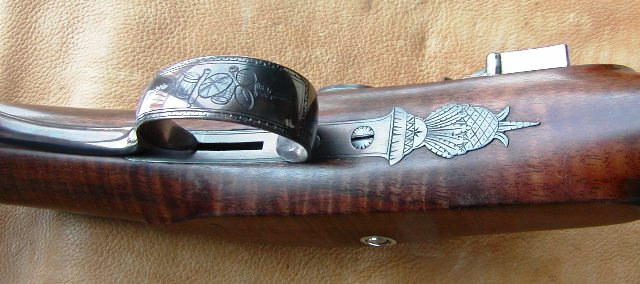

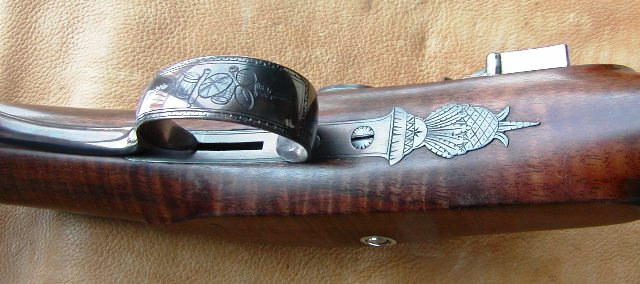

Next is fire or temper blued simply by heating the object to 575-585 degrees F. the screw heads are fire blued:

Here a lock is fire blued:

Temper bluing is attractive but it fades over time to gray. Recent research by Richard Colton showed that the detachable pans and all external lock screws on French trade guns were often fire blued while the rest of the lock was left bright. Scottish iron stocked pistols were also fire blued, which has faded away on almost all the surviving examples.

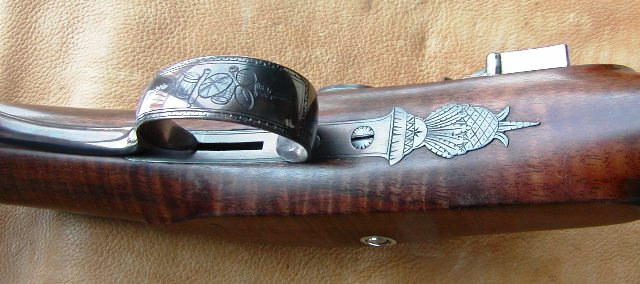

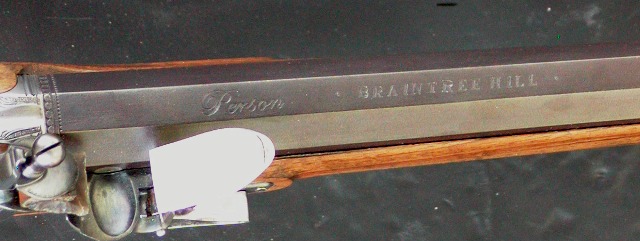

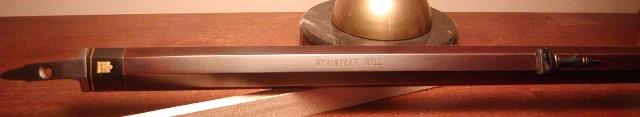

Packing steel and iron parts in charcoal to limit exposure to air and then heating the pack to 800-900 degrees imparts a deep blue we call charcoal bluing. Below are examples of charcoal bluing on a high-end gun.

Charcoal bluing of this quality is only achieved by bringing the metal surface to a high polish and heat treating, cooling and rubbing with oil and rottenstone, then repeating heating and rubbing until the color is deep, mirror like, and pretty durable. Charcoal bluing that looks uneven and spotty is because the metal was not polished sufficiently first and heat treating cycles were not repeated. There are many examples of original guns that exhibit that level of bluing.

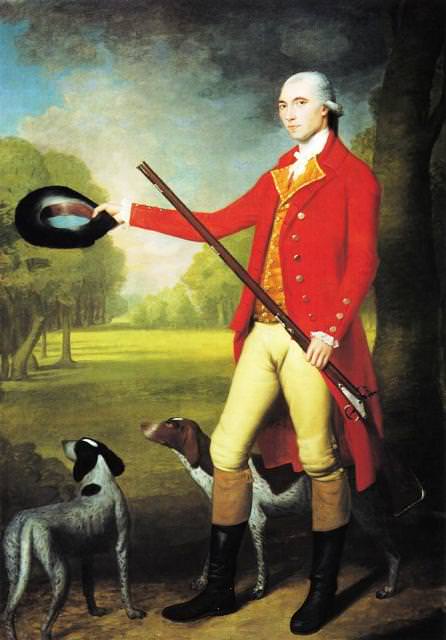

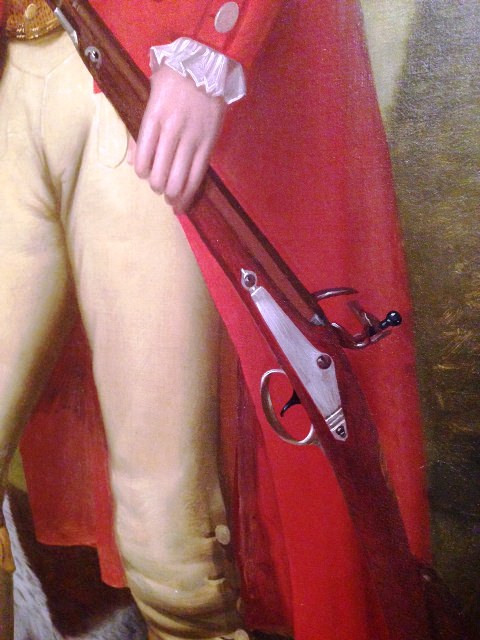

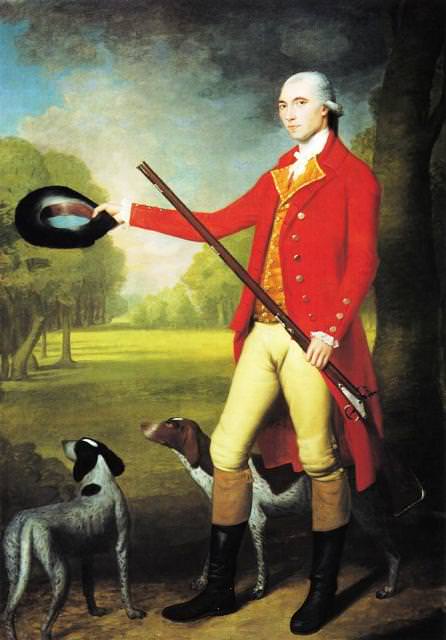

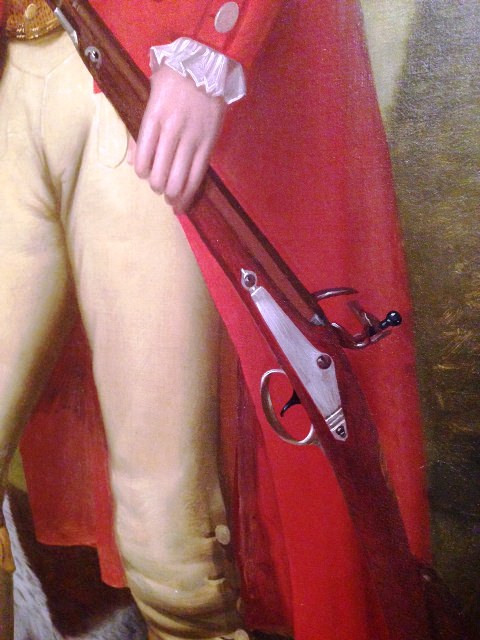

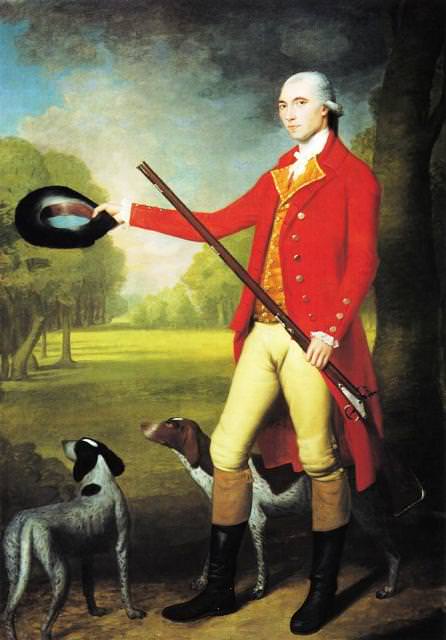

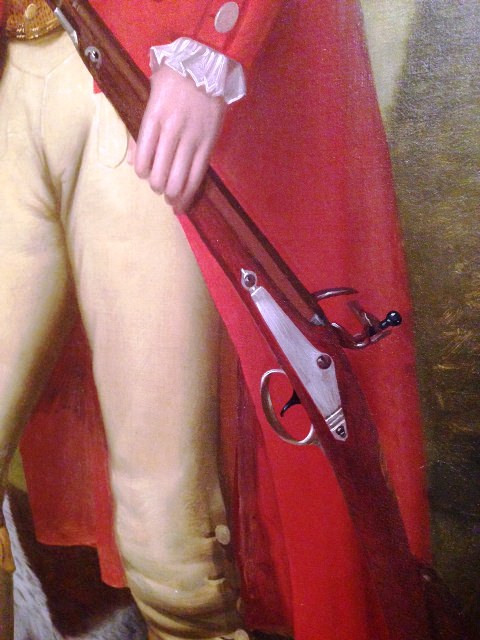

Rust browning using acid solutions was developed in the 18th century and became fairly common on British guns by the 1780s. It seems not to have become popular in America until about 1800. Below is a 1784 painting by Ralph Earle of a British sportsman with his fowler. The barrel is obviously browned:

Here is typical rust browning on an English gun styled from the late 1770s:

Here is a high-end example achieved by a high polish on the barrel and a very slow rusting solution.

It was a very durable and rust resistant finish and showed the patterns in stub twist and Damascus barrels very well.

During the latter half of the 18th century, British makers also preserved the case hardening colors as a decorative treatment and coloring for iron parts

Color case hardening was beautiful but not very durable. It was often painted with lacquer to preserve the finish as long as possible.

Perhaps as early as the 1790s but definitely during the early 19th century, gun makers discovered they could rust brown parts and then boil them in water to produce a deep and very dark bluing (rust bluing). Here is a high-end example:

This was a very durable finish and survived well into the 20th century as a common finish.

Depending on the quality, trade guns from the first half of the 18th century were likely finished in the white with more expensive versions occasionally having fire or charcoal blued components. During the later half of the century, browning probably became more common on better quality trade guns along with the older methods. During the 19th century, I believe there are trade gun examples showing the uses of all methods, including color-case hardening. I expect it all depended on price.

dave

During the first half of the 18th century barrels and iron /steel hardware were temper/fire/ blued, charcoal blued, painted with asphaltum (russetted), or left bright. Below are examples of each treatment. First, left bright. Polished iron (not steel) is amazingly resistant to rust:

Next is fire or temper blued simply by heating the object to 575-585 degrees F. the screw heads are fire blued:

Here a lock is fire blued:

Temper bluing is attractive but it fades over time to gray. Recent research by Richard Colton showed that the detachable pans and all external lock screws on French trade guns were often fire blued while the rest of the lock was left bright. Scottish iron stocked pistols were also fire blued, which has faded away on almost all the surviving examples.

Packing steel and iron parts in charcoal to limit exposure to air and then heating the pack to 800-900 degrees imparts a deep blue we call charcoal bluing. Below are examples of charcoal bluing on a high-end gun.

Charcoal bluing of this quality is only achieved by bringing the metal surface to a high polish and heat treating, cooling and rubbing with oil and rottenstone, then repeating heating and rubbing until the color is deep, mirror like, and pretty durable. Charcoal bluing that looks uneven and spotty is because the metal was not polished sufficiently first and heat treating cycles were not repeated. There are many examples of original guns that exhibit that level of bluing.

Rust browning using acid solutions was developed in the 18th century and became fairly common on British guns by the 1780s. It seems not to have become popular in America until about 1800. Below is a 1784 painting by Ralph Earle of a British sportsman with his fowler. The barrel is obviously browned:

Here is typical rust browning on an English gun styled from the late 1770s:

Here is a high-end example achieved by a high polish on the barrel and a very slow rusting solution.

It was a very durable and rust resistant finish and showed the patterns in stub twist and Damascus barrels very well.

During the latter half of the 18th century, British makers also preserved the case hardening colors as a decorative treatment and coloring for iron parts

Color case hardening was beautiful but not very durable. It was often painted with lacquer to preserve the finish as long as possible.

Perhaps as early as the 1790s but definitely during the early 19th century, gun makers discovered they could rust brown parts and then boil them in water to produce a deep and very dark bluing (rust bluing). Here is a high-end example:

This was a very durable finish and survived well into the 20th century as a common finish.

Depending on the quality, trade guns from the first half of the 18th century were likely finished in the white with more expensive versions occasionally having fire or charcoal blued components. During the later half of the century, browning probably became more common on better quality trade guns along with the older methods. During the 19th century, I believe there are trade gun examples showing the uses of all methods, including color-case hardening. I expect it all depended on price.

dave

Buck Conner

40 Cal

........., the only person I know of who made 12 gauge trade guns was Curly Gostomski. There may have been others, but Curly (the founder of North Star West) was the only one I know of. I believe that after North Star West changed hands and was taken over by Matt Denison, they made a very few trade guns in 16 gauge, but no twelves that I know of.

Bob I have owned a few 12 gauge trade guns, original and a Curly reproduction, one of the best firearms to put a mouse under your eye I have shot in 60 years. They can make you cry before you learn to hold your face lightly against the stock and slide with the recoil, oh - watch where your at on the stock.

One of our orignal NW guns in 12 gauge had a large hollow where your face sat to give the shooter relief from getting hit to hard. I sold a Sharpe's original in 20 gauge to Ryan R. Gale ( For Trade and Treaty: Firearms of the American Indians, 1600-1920 ) and a 16 gauge Sharpe's original, Hanson wanted that gun for the museum, said it was the nicest NWC gun he had ever seen. He offered $3,000 for the gun, then I told him how much my father paid for it during the depression - $1.15 cents and had to make payments on it for a few months. I sold it for $4,600 (nice profit). When still collecting our family records show a dozen NW guns in 16 gauge for later period guns made after 1850. Many 12 gauge originals same for 20 gauge. We had many of them throught out the years and lots of parts gathered up being so cheap - back east they were squirrel guns or barn guns.

.

Buck Conner

40 Cal

During the first half of the 18th century barrels and iron /steel hardware were temper/fire/ blued, charcoal blued, painted with asphaltum (russetted), or left bright. Below are examples of each treatment.

Depending on the quality, trade guns from the first half of the 18th century were likely finished in the white with more expensive versions occasionally having fire or charcoal blued components. During the later half of the century, browning probably became more common on better quality trade guns along with the older methods. During the 19th century, I believe there are trade gun examples showing the uses of all methods, including color-case hardening. I expect it all depended on price.

Price was always questioned, and there weren't many of the fancy finishes like you showed for the Indian trade. They were ment to be used and used up they were. The Nobleman, Dukes and high society folks are the ones that had the fancy guns like shown. The cleanest and nicest trade gun that most collectors have seen was one at different museums in Denver over the years (was on loan and passed around for years).

Here's a copy of that gun by Doc White.

A North West gun in 50 caliber smoothbore. Reproduction of an early one often seen in gunshows, new and apparently unused. Very plain but sturdy walnut stock, antique rust blued barrel and lock, trigger guard stained dark with time, brass dragon and buttplate nailed on, like the original.

Hanson had some neat information on traders in the New England states that made a good living with the Indian trade supplying them with NW guns, powder, lead and cleaning supplies.

This went on for years until (this is a quote according to Hanson's information) "one of those French (bastard) traders showed them how to rebuild their guns and supplied them with lock parts and other pieces". That killed sales for a while I would think.

Last edited:

plmeek

40 Cal.

I recently purchased a prior owned 12 ga trade gun. It is in the white for its entire lengthy existence. I was thinking, so I briefly researched, one article I read, the writer stated that a large number if not most Trade Guns, came "blued". Would that mean some sort of external barrel treatment or would they have been in the white.?????

The answer to your question depends a lot on the period you are interested in. Early trade guns of the 17th and most of the 18th century appear to have bright barrels.

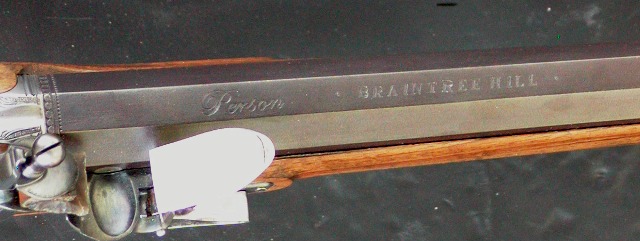

We don't have a lot of surviving documents on fur trade companies orders. A good portion of Hudson's Bay Company records survive and have been thoroughly researched by S. James Gooding and published in his book, Trade Guns Of The Hudson's Bay Company - 1670-1970. Gooding found a record for December 20, 1780 that mentions browned barrels. This may be the earliest the HBC ordered guns with brown barrels.

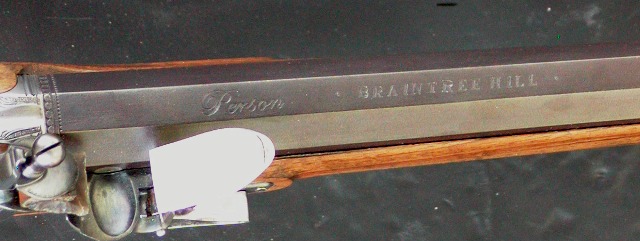

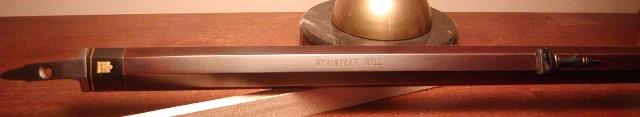

At the time that the Northwest Company merged with HBC in 1821, an inventory of guns supplied by Thomas Barnett & Son to the Northwest Co. was conducted. In it were "440 NW guns, London proved blue barrels, same as Hudson's Bay, 5 Neat fowling pieces, brown barrels to take out with false breech, ribs, roller locks, neat steel furniture, 5 Do. Do. (dito for neat fowling pieces) platina holes (platinum vent liners) twisted barrels, 20 neat fowling pieces exactly assorted as above, 72 dble bridle locks, hardened, polished and engraved with screws." In this case, the fowling pieces which were finer and more expensive guns than the common NW trade gun had browned barrels.

This suggests that by the 1820's, NW guns with blue barrels were becoming the norm for the Northwest Company and HBC. As will be seen below, these were likely brilliant temper or fire blued in contrast to charcoal blue or rust blue.

The other significant records we have for fur company orders are the American Fur Company records and the records of J. Joseph Henry and his son, James, who made rifles and several hundred NW trade guns for the AFC and some other companies. The American Fur Company records before 1822 were destroyed in a fire. They were ordering nearly all their guns (trade guns and rifles) before that date from England. They ordered NW trade guns with bright, blue, and brown barrels.

The AFC wanted to find an American source for NW guns and placed an order with J.J. Henry in Dec. 1826 for 200 NW guns. This was followed in Apr 1828 with a contract for 500 NW guns.

Ramsey Crooks reported to Henry that he was not satisfied with the color of the barrels on these guns. He wrote in a letter to Henry dated Feb 14, 1829 stating, "I do not think them of that bright lively blue which distinguishes the English and which I trust you will bestow your most particular attentions until your Guns are really of as fine a color as those we have been in the habit of importing when I shall readily pronounce them every way equal."

The English undoubtedly put a finer polish on their barrels and had better temperature control to achieve the brilliant blue on the barrels.

The temper or fire blue is not a durable finish, but apparently the AFC customers didn't care and liked the bright blue color when the gun was new.

Wow! Lots of good input!

plmeek, Dave person, and Buck Conner pretty well covered everything with regard to barrel finish. To recap, there is evidence (see plmeek's post) that some Northwest guns were ordered with browned barrels as early as 1780, but the references I have on hand (primarily Gooding and Hanson) suggest most of them, over the course of the gun's history, were blued. Some were certainly browned, and Phil has provided evidence that some were also bright.

Regarding 12 gauge trade guns, one modern made example which I had forgotten to mention is the Dixie Brown Bess Trade Gun, which at .75 caliber is actually closer to 11 gauge. This gun is really just a Pedersoli "Brown Bess Carbine" with a "serpent" sideplate added on. The sideplate is not visible in this picture, but you can get an idea of the gun's overall appearance:

This Dixie/Pedersoli Trade Gun (not to be confused with the 20 gauge Pedersoli Indian Trade Musket) is also offered as a kit with virtually all of the inletting already done, so the kit is essentially a gun in the white. I suppose it is possible that your gun may be one of those, left unfinished and still in the white. If this is the case, by all means, finish it as you choose! These guns are still in production.

Just for reference, here are a couple of pictures (borrowed from the Midland Agrarian website) of one of the big-bore Curly Gostomski trade guns:

These early ones used the Pedersoli LOTT lock:

Just for comparison, and to show some of the markings, here is a reproduction of a very fine old Belgian Northwest gun lock, from Chris Hirsch. Note the "Fox in Circle" stamp, generally associated with the old Northwest Company but frequently counterfeited:

This lock is from a Parker-Field Northwest gun, and has the Hudson's Bay Company "Tombstone Fox" mark, which may be hard to see in this image:

This has been an interesting thread. I look forward to reading more. We would still like to see pictures of the original poster's gun, though.

Best regards,

Notchy Bob

plmeek, Dave person, and Buck Conner pretty well covered everything with regard to barrel finish. To recap, there is evidence (see plmeek's post) that some Northwest guns were ordered with browned barrels as early as 1780, but the references I have on hand (primarily Gooding and Hanson) suggest most of them, over the course of the gun's history, were blued. Some were certainly browned, and Phil has provided evidence that some were also bright.

Regarding 12 gauge trade guns, one modern made example which I had forgotten to mention is the Dixie Brown Bess Trade Gun, which at .75 caliber is actually closer to 11 gauge. This gun is really just a Pedersoli "Brown Bess Carbine" with a "serpent" sideplate added on. The sideplate is not visible in this picture, but you can get an idea of the gun's overall appearance:

This Dixie/Pedersoli Trade Gun (not to be confused with the 20 gauge Pedersoli Indian Trade Musket) is also offered as a kit with virtually all of the inletting already done, so the kit is essentially a gun in the white. I suppose it is possible that your gun may be one of those, left unfinished and still in the white. If this is the case, by all means, finish it as you choose! These guns are still in production.

Just for reference, here are a couple of pictures (borrowed from the Midland Agrarian website) of one of the big-bore Curly Gostomski trade guns:

These early ones used the Pedersoli LOTT lock:

Just for comparison, and to show some of the markings, here is a reproduction of a very fine old Belgian Northwest gun lock, from Chris Hirsch. Note the "Fox in Circle" stamp, generally associated with the old Northwest Company but frequently counterfeited:

This lock is from a Parker-Field Northwest gun, and has the Hudson's Bay Company "Tombstone Fox" mark, which may be hard to see in this image:

This has been an interesting thread. I look forward to reading more. We would still like to see pictures of the original poster's gun, though.

Best regards,

Notchy Bob

Last edited:

This was a really thorough and well presented review. Thanks for taking the time to post your research here. The photos are tremendously useful also. (As an aside, the English gentleman must have been quite proud of his gun to be sure the artist captured the wonderful details as he did.) It’s refreshing to read such a scholarly review such as yours. Thanks Dave.Hi,

During the first half of the 18th century barrels and iron /steel hardware were temper/fire/ blued, charcoal blued, painted with asphaltum (russetted), or left bright. Below are examples of each treatment. First, left bright. Polished iron (not steel) is amazingly resistant to rust:

Next is fire or temper blued simply by heating the object to 575-585 degrees F. the screw heads are fire blued:

Here a lock is fire blued:

Temper bluing is attractive but it fades over time to gray. Recent research by Richard Colton showed that the detachable pans and all external lock screws on French trade guns were often fire blued while the rest of the lock was left bright. Scottish iron stocked pistols were also fire blued, which has faded away on almost all the surviving examples.

Packing steel and iron parts in charcoal to limit exposure to air and then heating the pack to 800-900 degrees imparts a deep blue we call charcoal bluing. Below are examples of charcoal bluing on a high-end gun.

Charcoal bluing of this quality is only achieved by bringing the metal surface to a high polish and heat treating, cooling and rubbing with oil and rottenstone, then repeating heating and rubbing until the color is deep, mirror like, and pretty durable. Charcoal bluing that looks uneven and spotty is because the metal was not polished sufficiently first and heat treating cycles were not repeated. There are many examples of original guns that exhibit that level of bluing.

Rust browning using acid solutions was developed in the 18th century and became fairly common on British guns by the 1780s. It seems not to have become popular in America until about 1800. Below is a 1784 painting by Ralph Earle of a British sportsman with his fowler. The barrel is obviously browned:

Here is typical rust browning on an English gun styled from the late 1770s:

Here is a high-end example achieved by a high polish on the barrel and a very slow rusting solution.

It was a very durable and rust resistant finish and showed the patterns in stub twist and Damascus barrels very well.

During the latter half of the 18th century, British makers also preserved the case hardening colors as a decorative treatment and coloring for iron parts

Color case hardening was beautiful but not very durable. It was often painted with lacquer to preserve the finish as long as possible.

Perhaps as early as the 1790s but definitely during the early 19th century, gun makers discovered they could rust brown parts and then boil them in water to produce a deep and very dark bluing (rust bluing). Here is a high-end example:

This was a very durable finish and survived well into the 20th century as a common finish.

Depending on the quality, trade guns from the first half of the 18th century were likely finished in the white with more expensive versions occasionally having fire or charcoal blued components. During the later half of the century, browning probably became more common on better quality trade guns along with the older methods. During the 19th century, I believe there are trade gun examples showing the uses of all methods, including color-case hardening. I expect it all depended on price.

dave

I do not believe that it is a Pedersoli... There are no markings on the barrel. The lock is marked Wilson 1821 and a sitting fox facing right

I have a DOC WHITE, gun in 20 gauge and it is browned.

Price was always questioned, and there weren't many of the fancy finishes like you showed for the Indian trade. They were ment to be used and used up they were. The Nobleman, Dukes and high society folks are the ones that had the fancy guns like shown. The cleanest and nicest trade gun that most collectors have seen was one at different museums in Denver over the years (was on loan and passed around for years).

Here's a copy of that gun by Doc White.View attachment 59964

A North West gun in 50 caliber smoothbore. Reproduction of an early one often seen in gunshows, new and apparently unused. Very plain but sturdy walnut stock, antique rust blued barrel and lock, trigger guard stained dark with time, brass dragon and buttplate nailed on, like the original.

Hanson had some neat information on traders in the New England states that made a good living with the Indian trade supplying them with NW guns, powder, lead and cleaning supplies.

This went on for years until (this is a quote according to Hanson's information) "one of those French (bastard) traders showed them how to rebuild their guns and supplied them with lock parts and other pieces". That killed sales for a while I would think.

Danny Caywood makes several types of trade guns, including Northwest guns, Wilson "Chief's Grade" guns, and I believe two types of French fusils. He will sell any of these "in the white" or finished. Come to think of it, I believe he only offers blued barrels on his trade guns. I don't think he will brown them. He also offers an English game gun in 12 gauge, but it is different from his trade guns, and I don't know that he will make a trade gun in 12 gauge.I do not believe that it is a Pedersoli... There are no markings on the barrel. The lock is marked Wilson 1821 and a sitting fox facing right

Anyway, he does make locks with "Wilson" and "fox in circle" markings. I have one of his Northwest guns in 24 gauge. He does good work!

Curly Gostomski also started making his own locks at some point. I think these did have a "sitting fox" stamped on the plate, but I'm not so sure about the Wilson markings. It will be great when you can show some pictures.

Notchy Bob

Last edited:

Similar threads

- Replies

- 10

- Views

- 613

- Replies

- 3

- Views

- 335