This what my anti virus says about this page

Potentially unwanted content found |

This what my anti virus says about this page

Potentially unwanted content found | |

The site looks like it hasn't been maintained for a while now. I'll paste the section about using water and Ballistol here so you can read it.

Finding the correct amount of “slickness” for your patch lube

The final variable that affects the accuracy of your load and the size of your group is the patch lubricant. A patch that is slicker than others because it has more lubricant on it is not going to have the same amount of friction going out of the barrel. Less friction equals less pressure which will equal a lower velocity. That ball with lower velocity will not strike the target in the same place as the others. Getting a consistent amount of lubricant on every patch equals consistent velocities for every shot.

You can control the amount of lubrication on and in the patch material by using a water-soluble oil. Yes, you read that correctly. An oil that dissolves and mixes thoroughly with water. The cooling fluids used by machinists to keep the cutting head of their machines from overheating is one of these types of oil. ‘Ballistol’ is an easy to obtain oil of this type and is available in smaller quantities. This is also one of the ingredients in moose milk recipes so you will need to have some on hand. Most good gun stores will have it, if not it can be ordered over the internet.

Mix this oil with water and soak your strips of patching in it until they are fully saturated. Then lay those strips out flat on a non-porous surface to dry. The water will evaporate out of the fabric leaving only the oil. Always lay the fabric strips out flat. If you hang them to dry the water/oil solution will run down the strip leaving more oil at the bottom and less at the top.

You want the same amount of oil equally distributed through the entire strip of patching material. Once dry, roll your strips of patching up and store them in a plastic baggie or air tight container such as an empty pill bottle or Tupperware container. With this method you insure that every patch you load will have the exact same amount of lubricant, thus eliminating one more variable that affects the accuracy of your load.

To use this method to control the exact amount of oil that is distributed in the patching material you will test different ratios of water to oil. Start by putting one measure of oil in a glass jar. I use a one ounce measuring cup similar to those used to measure a dose of liquid medicine. Then add five measures of water and mix well. Soak one strip of your best thickness of patching material in this mixture, squeeze the excess out of the fabric back into the jar. Lay that strip out flat to dry and mark it 5-1. Then add another measure of water to the mix and soak another strip. Lay it out to dry and mark it 6-1. Continue to add one measure of water and soak one strip for a 7-1 mix and so forth until you reach a solution of 9-1.

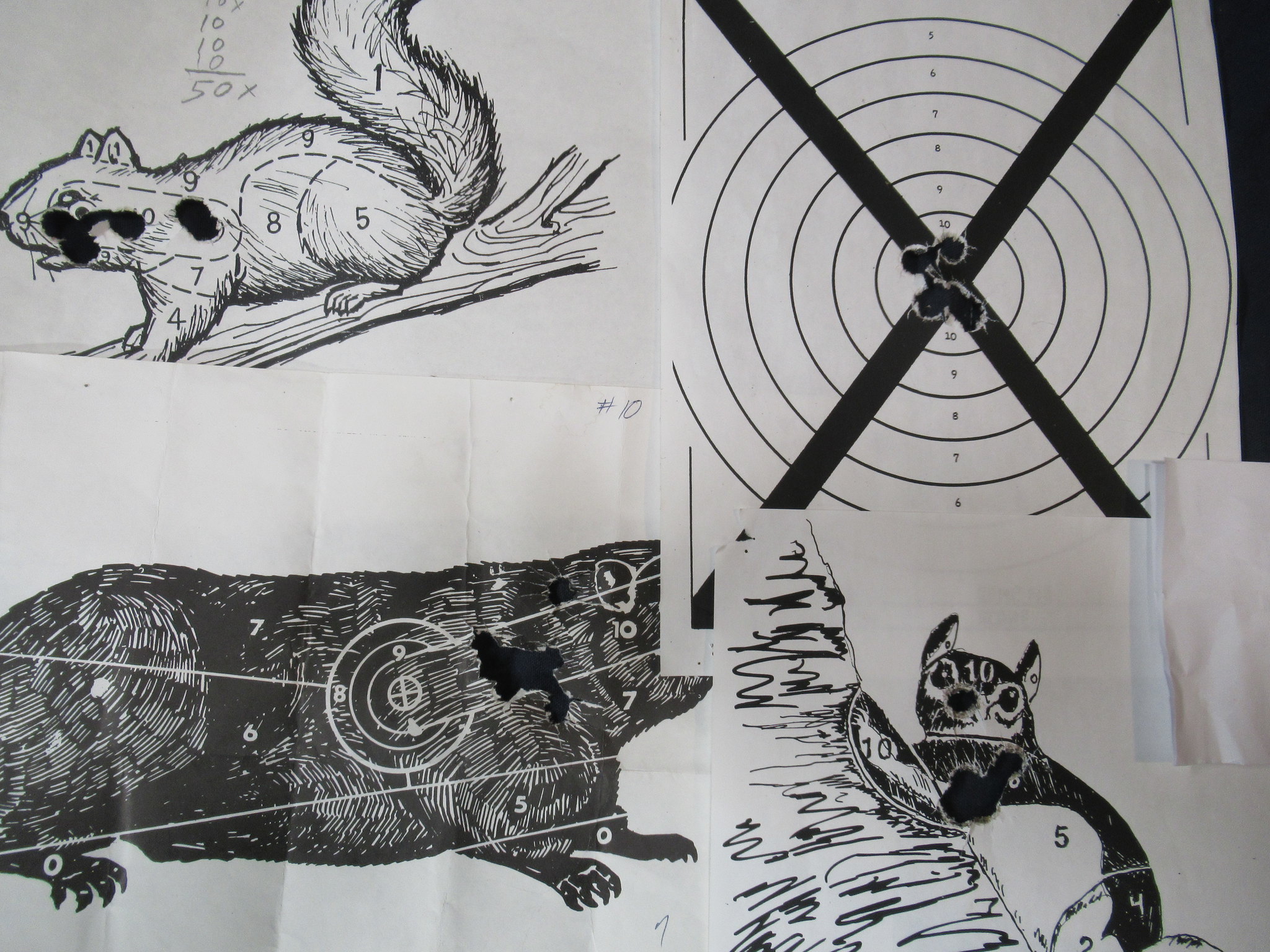

Go back to the range and load your best powder charge and ball combination with the 5-1 mix lubricated strip and fire a five shot target. Do not add any additional lubricant to these patch strips. Record all the data on the target and repeat with a new target changing only the patching in your load to the strip marked 6-1. Do this until you have shot a five shot target with each strip of patching or until it becomes too difficult to seat the ball due to the patch strip being too dry. You will again notice that the groups on the targets show a pattern of becoming smaller and rounder until the load becomes so tight that pounding the ball out of round causes the group to open up or the load is so tight you can’t get it started in the muzzle.

The reason this works is because the oil mixes evenly with the water and the fabric will only absorb so much of this mixture until it is fully saturated. Once it reaches total saturation the material will take no more. Allowing the fabric to air dry lets the water evaporate away leaving only the oil in the material. Mixing more water into the oil causes the fabric to absorb more water and less oil so less oil remains in the material after the water has evaporated. In this manner we are able to control precisely the amount of oil applied to our patching. Now study your test targets again and there on the target with the smallest group will be written the best mixture of water to oil for your patching in that particular rifle.

This water-soluble oil method is absolutely the best, most consistently accurate patch lube method in use today. Unlike grease or straight oils, you can precisely control how much lubricant is applied to every patch. Unlike spit or wet lube mixtures this will not freeze in cold weather. It will not dry out if the load sits in the barrel during a long hunt or while waiting to take your shot on the range. It won’t soak into your powder charge. It will not leave a built up layer of crud in your bore like some of the concoctions of lip balm, waxes and grease. It will not cause a ring of rust inside your barrel if it is left in the bore over a period of time. Unlike Crisco, lard, or olive oil, you don’t want to use it to cook your breakfast. But you can control precisely the amount of lubrication on your patching in order to discover exactly how much “slickness” your barrel requires to shoot its best groups.

Typically, most shooters who use this method will find their best groups to be with a 7-1 or 8-1 mix of water to oil. When I lived in a more humid area of the country that was the best mix for my guns. But after I moved to the High Desert of New Mexico with its drier humidity, I found that I had to change my lube mix to a 3-1 mixture. The 8-1 mix that shot so well before was now so dry that I could not get that load down the barrel without pounding the heck out of the ball. This is because the amount of water that will evaporate from the patching material cannot exceed the amount of moisture in the air. In a dryer climate more water can evaporate from the patching. So consider that your results may vary according to your local conditions of humidity and adjust the mixture accordingly. Nonetheless, this method will reveal the correct amount of lubricant for your conditions and the most accurate loading for your rifle.