After this post I hesitate to participate. I have had many old guns apart. Many of the guards of this style are concave on the bottom side to conform to the slightly rounded surface of the bottom of the stock in this area. If Dave would take his antique English fowlers apart he would see this.

Seeing as how the Edward Marshal gun was made in America it would be ridiculous to cut off the finial because it's too 'fancy" for American work. American gunmakers weren't untalented dolts. Don't cut those finials off! INLET THEM!

Did I ever say American Gunsmiths were untalented dolts? Did I ever say American gunsmiths were incapable of fine work?

Buckskin does not have to really "Cut" the front finials off as he accidentally broke the guard! It's cracked and likely will not survive the finish work in one piece. Worse yet he could inlet it partially broken...break the guard and have to order a new one...one that does not fit the inlet.

Since the front finials are a small detail. Since their absence would have no real bearing on the overall architecture of this rifle I feel it would be fine for him to proceed without them. The guard still needs work. In my opinion, by judging other rifles of the period that rifle would finish just fine without the three acorns.

It's his choice. If he wants to keep them, he can repair the guard or likely the easiest solution...order a new one. I'll say it again....the rifle will finish just fine with out them. that's my opinion and I respect yours.

Ultimately it's Buckskin's choice.

(the original Rifle)

http://www.erickettenburg.com/Site_2/Part_12,_contd._files/Mar8_1.jpg

http://www.erickettenburg.com/Site_2/Part_12,_contd._files/Mar7_1.jpg

Compare that link to this....

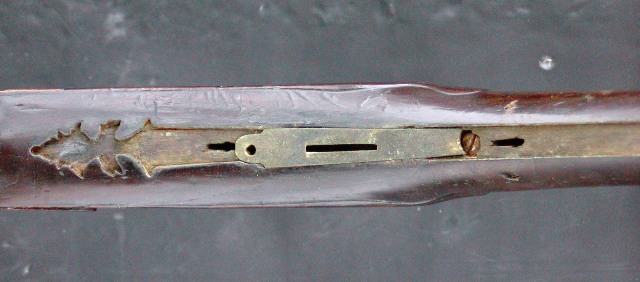

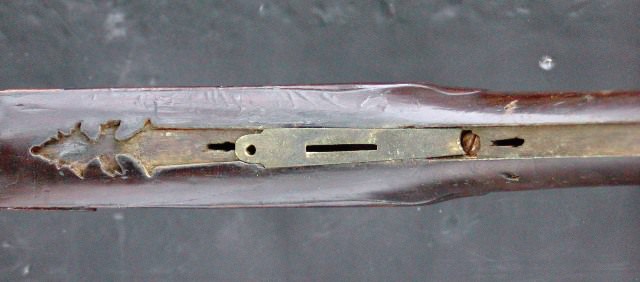

Look at how the trigger guard is executed on the Marshall Rifle. 2 main things. The guard (appears) to be set rather deep. It may not be as deep as it appears...if so there has been a lot of file work.

(Buckskin's Rifle) It's Obvious the guard needs to come down. As Mr. Person advised, it's a good idea to go head and refine those lock panel details....then work on the guard. To get that guard down....the guard will have to be notched at the trigger plate. That and the file work.

Thoughts on file work.....

Cast guards like in the 18th Century were rough indeed out of the mould. They were pretty much just blobs. Most of the time the mould halves were slightly offset. Look at the links and you can see this on the original. Note that the guard is not perfectly symmetrical. It was the file skill of the smith that makes these castings artful, making the imperfect look very good.

Modern wax cast stuff looks really good. It looks so good that a new builder may just "clean it up" when in reality it's still pretty much a blob...a clean looking blob, but a blob needing a great deal if file work all the same.

Buckskin, It would be a good idea to study photos of the original and try to recreate the look and fit of that guard, even without the finials.

I'm not into this rifle, Buckskin is. From what I see now.....

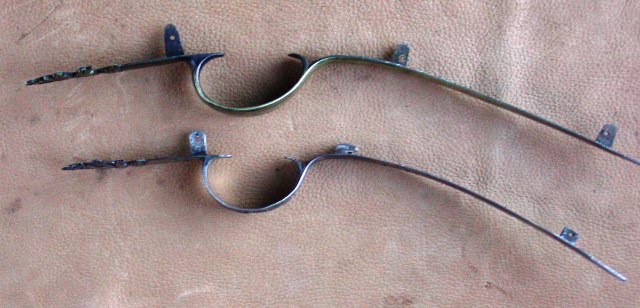

I Like to get the guard nearly file-finshed before I start putting it on a rifle. Why? If I have to tweak the guard shape (by filing) later...it may not fit the started inlet. I like to file a draft on the bottom (wood) side to meet the inlet line. This draft aids in letting the guard down. Trigger plate notch...there, it's a slow go.

Bending....guards are funny things where the bend needs to be tweaked may not be where you think it needs to be tweaked. To get the front finial down.....you may need to work at the bow. Then it may need to be twisted a little. It my be fine as is....it's one of those things....what ever is necessary.

Untitled

Untitled by

Travis Brown, on Flickr

Untitled

Untitled by

Travis Brown, on Flickr

Untitled

Untitled by

Travis Brown, on Flickr

Untitled

Untitled by

Travis Brown, on Flickr

Untitled

Untitled by

Travis Brown, on Flickr

This is rough as cob sand casting. This is an example of the great deal of filework required. Since it was cast crooked, it will not be symmetrical. Other than the lugs this castings is ready to be fit to the stock. The profile is set. While it needs some more cosmetic work to clean it up in spots it's ready to be letted .

Buckskin I honestly feel you have lots of lee way here and the main priority ought to be the execution of the workmanship, architecture and mechanical function....

Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled