Metalshaper

40 Cal.

- Joined

- Jul 6, 2004

- Messages

- 481

- Reaction score

- 132

Colonial,

I agree with Pat, a Porta band works great!!

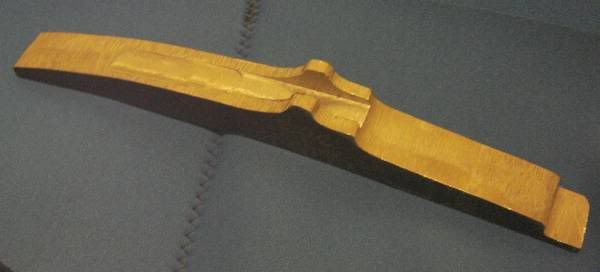

I did quite a bit of drilling and cutting,( just like your doing ) when I made my "Miss Muley". then I was gifted a cast off saw. My buddy MRW, helped make a saw stand for me.. This support frame makes it work like a small vertical bandsaw and I can concentrate on guiding the cut,, instead of balancing the weight of the saw.

here's a pic of the saw mounted to the frame..

Respect Always

Metalshaper

I agree with Pat, a Porta band works great!!

I did quite a bit of drilling and cutting,( just like your doing ) when I made my "Miss Muley". then I was gifted a cast off saw. My buddy MRW, helped make a saw stand for me.. This support frame makes it work like a small vertical bandsaw and I can concentrate on guiding the cut,, instead of balancing the weight of the saw.

here's a pic of the saw mounted to the frame..

Respect Always

Metalshaper