gmww

70 Cal.

- Joined

- Sep 4, 2004

- Messages

- 4,693

- Reaction score

- 4

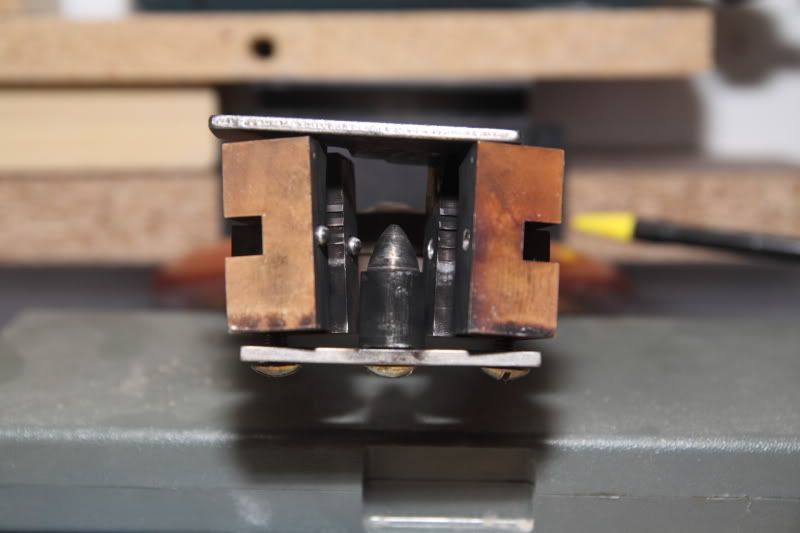

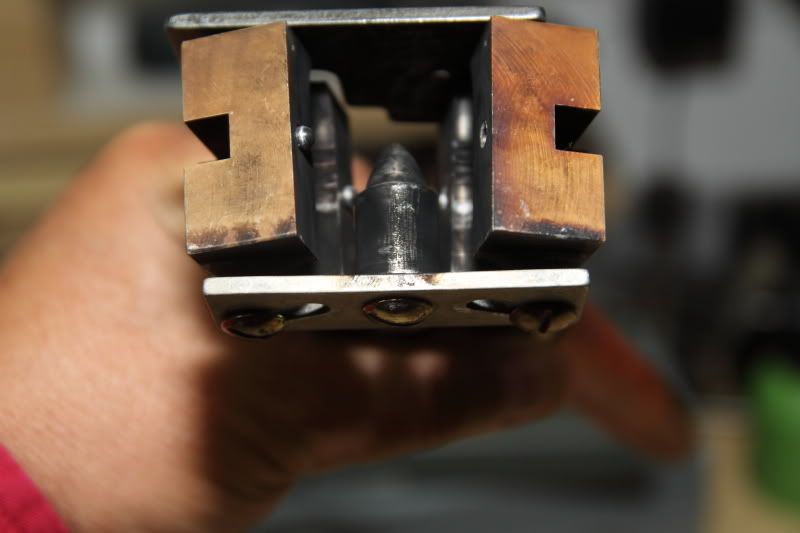

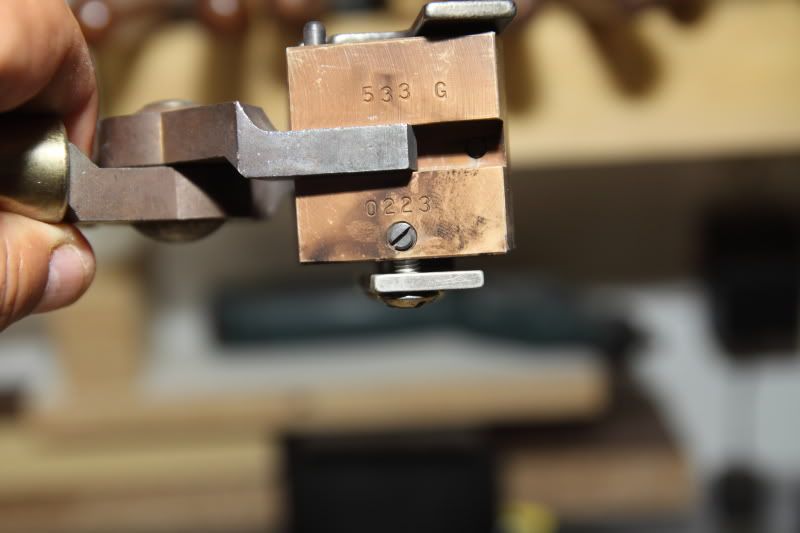

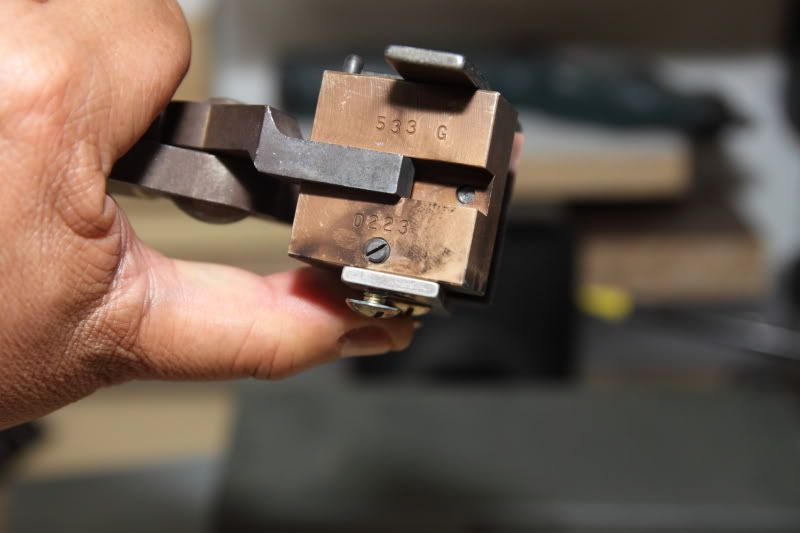

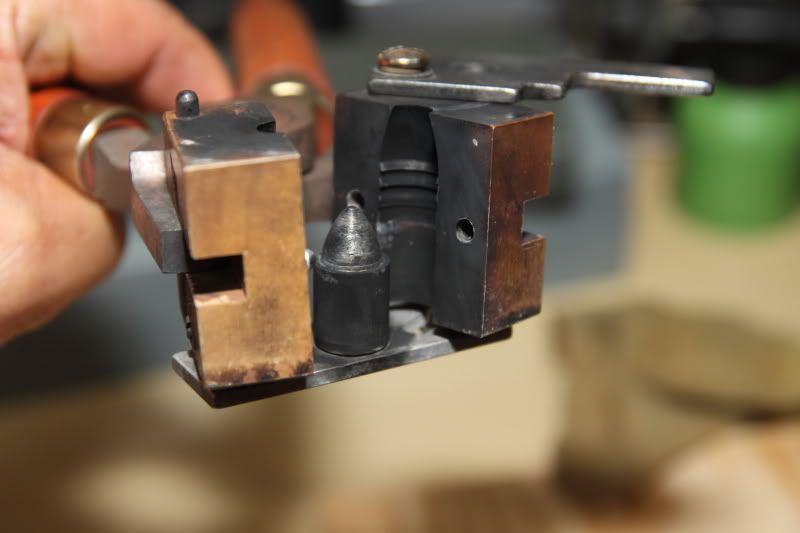

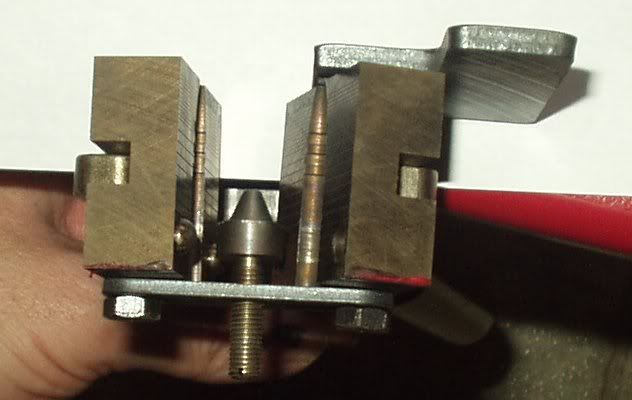

In preperation for an up coming hunt, I've been casting Great Plains and Minie ball bullets from Lyman molds. This is for my fast twist .54. I've notices variations in the final cast bullets. Not so much in the Great Plains but more with the Minie ball mold.

The first thing I noticed was they don't cast 425 grns as the box says it would. They are ranging from 380's to 405 grns. Mostly in the 390's.

At first I thought I got my lead supply mixed up and was casting hard cast. I checked and these are my soft lead supply. My thumb nail easily scratched the lead. Any thoughts? :hmm:

The first thing I noticed was they don't cast 425 grns as the box says it would. They are ranging from 380's to 405 grns. Mostly in the 390's.

At first I thought I got my lead supply mixed up and was casting hard cast. I checked and these are my soft lead supply. My thumb nail easily scratched the lead. Any thoughts? :hmm: