Well, over the summer I bought three firearms from the trading area of this forum and ended up never rebuilding them. Two of them are now complete for all intensive purposes, and the third is now in good firing order. Here are the pictures:

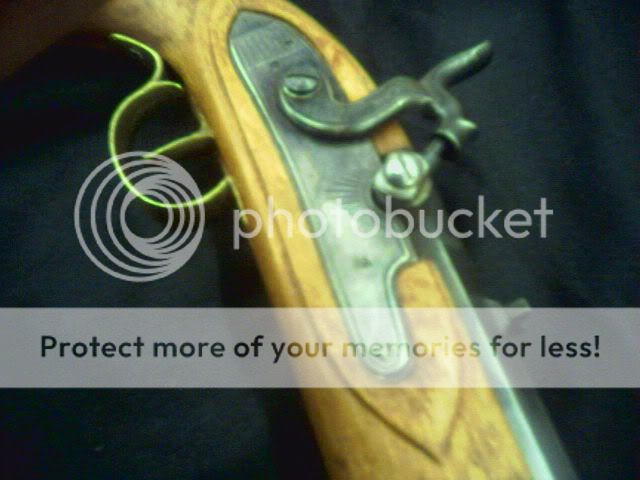

This is the flintlock that I consider to be complete. It has 3/8" american flints from Dixie. Right now I'm still figuring out how to get it to fire reliably, but when I do get it to fire, it is more accurate than I imagined it would be. I honestly am not sure what the stock is made of - it almost looks like it could be walnut but I think it's too light for that.

The rear sight was badly abused when I got this gun, it had no touch hole liner, and the lock mortise was too loose to be considered safe to fire. I fixed all of these problems. The greatest challenge by far was making the rear sight look good again, as it required substantial grinding, than sanding to get it to work.

The stock was unfinished when I bought it, and I was so struck by the wood on this gun, I decided not to stain it, but rather just coat it with Tung Oil. That picture represents 3 coats. I believe I may put 2 or 3 more on it. I am leaving the barrel white and natural as I have left all of my projects thus far. I have found it takes a fair degree of commitment to keep my guns looking shiny this way though. It's tough to see, but the trigger guard is actually broken here. I haven't soldered it back together yet, and it is so tough to notice, I might just take my time getting around to fixing that. The only other notable thing left to say about this firearm is that it says "Jukar" on the side, which I believe would most likely make it a CVA.

This firearm is also a Jukar. I am not sure if the drum that I got for it is the correct drum or not, but after some grinding it fit tightly, and is relatively permanently installed courtesy of some locktite. The hammer than was heated with a plumber's torch and bent slightly so it would mesh nicely with the nipple. I installed a new tang screw in it because the old one was the wrong size. The upper trigger guard screw is sheared off, so the trigger guard is only held in by one screw. The mortise is so tight though, I don't think I'm going to bother to fix it.

This gun I could use an opinion on, however. It has no nosecap, and nosecaps aren't available from CVA. I'm not sure but I think this is what is called a "Kentucky Pistol". In any case, I was thinking about cutting it down to a halfstock pistol, and welding in the two holes where the nosecap screws would have gone.

Anybody have an opinion to share about this? I think it would make this firearm unique. I don't care about historical accuracy on this particular one because I plan on shooting it as much as possible.

I'm not a huge fan of the wood on this one, but it is in pretty good shape overall. Rather than carefully strip the barrel, I haphazardly ran a scotch bright pad over the badly scratched bluing and came away with a unique effect of highlighting around the drum and muzzle. I think it gives the gun the permanent appearance of being dirty from having been fired, so I might simply leave it like this.

This image is a little out of focus, but this derringer is so small it's hard to fill a frame with it. This is a little 41 caliber smoothebore boxlock. It was unassembled when I got it in a very old box. I believe this to be the same as the kit you can buy from Dixie. It is made in Italy, I believe by Pietta.

I didn't like the grips on it originally, as I didn't do as good of a job fitting them, and I didn't care for the look of the wood so much. One night while polishing it with some Brasso, I accidentally smudged some black on the grips and actually liked the effect, so I blacked the gribs, sanded them lightly with some 220 grit paper, and applied 3 coats of Tung Oil for what now look like fairly handsome grips.

I also have some acrylic solid surface material I've thought about cutting into an alternate set of grips.

I have decided to leave the gun as rough as possible so as to give it a crude, maybe original appearance. The brass is scratched, the grips are blackened, and the hammer still has a lot of the casting marks in it, although it is heat treated. After a good polishing, the gun looks like it really might have been carried in the pocked of a gambler from the 1850s.

Here is a picture of them all together:

I am very pleased with my work overall. I'm still learning a lot about how to fit and assemble these kits, but I've gotten to learn a lot more since my first kit.

The flintlock is cool to shoot, and it represents what I originally wanted when I first posted on this site. In retrospect, I'm not sure if I would have continued shooting black powder had I first bought a flintlock. I am still having some difficulty getting it to reliably ignite at the range, although I am using PyrodexP in the flashpan. I plan on buying some 4F powder ASAP now that I have the gun working.

I shot all 3 guns today at the range. The derringer I shot with .395 roundball and 015 patch. it is frighteningly inaccurate as I expected, although from 10 paces I can usually hit a B34-RC target.

The flintlock shoots surprisingly well when it shoots. The bore is nearly perfect on this gun, and I suspect it must not have been fired very much.

The percussion lock shoots pretty well, but the bore had developed some rust. I brushed and brushed and cleaned, and eventually got most of the rust out, but there was some minor pitting in the bore. I worked the sear pin with a Carborundum rod to smooth out the trigger. First two shots of the day I nailed dead center on the same B34 RC target from 15 yards. The last 3 shots were a little less consistent, but probably still within an 8 inch circle or so.

Both of the larger pistols are .45 caliber. I shoot .440 roundball with a 010 patch. I have heard of some people patching with a 015, but I haven't tried that yet. I usually bring a scoop with me from my Lee scoop set when I shoot black powder, so today I made all of my shots with a 35 grain charge of PyrodexP powder. The derringer of course can NOT be fired with this charge, but rather instead I shot about a 9 grain charge of Pyrodex P.

And that's all I have to report! Feel free to criticize where you see problems, and offer advice, solicited or otherwise. Plenty of pictures here for everybody to see!

This is the flintlock that I consider to be complete. It has 3/8" american flints from Dixie. Right now I'm still figuring out how to get it to fire reliably, but when I do get it to fire, it is more accurate than I imagined it would be. I honestly am not sure what the stock is made of - it almost looks like it could be walnut but I think it's too light for that.

The rear sight was badly abused when I got this gun, it had no touch hole liner, and the lock mortise was too loose to be considered safe to fire. I fixed all of these problems. The greatest challenge by far was making the rear sight look good again, as it required substantial grinding, than sanding to get it to work.

The stock was unfinished when I bought it, and I was so struck by the wood on this gun, I decided not to stain it, but rather just coat it with Tung Oil. That picture represents 3 coats. I believe I may put 2 or 3 more on it. I am leaving the barrel white and natural as I have left all of my projects thus far. I have found it takes a fair degree of commitment to keep my guns looking shiny this way though. It's tough to see, but the trigger guard is actually broken here. I haven't soldered it back together yet, and it is so tough to notice, I might just take my time getting around to fixing that. The only other notable thing left to say about this firearm is that it says "Jukar" on the side, which I believe would most likely make it a CVA.

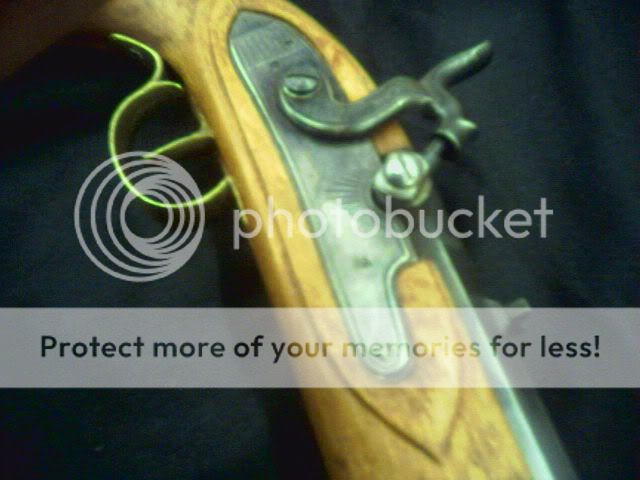

This firearm is also a Jukar. I am not sure if the drum that I got for it is the correct drum or not, but after some grinding it fit tightly, and is relatively permanently installed courtesy of some locktite. The hammer than was heated with a plumber's torch and bent slightly so it would mesh nicely with the nipple. I installed a new tang screw in it because the old one was the wrong size. The upper trigger guard screw is sheared off, so the trigger guard is only held in by one screw. The mortise is so tight though, I don't think I'm going to bother to fix it.

This gun I could use an opinion on, however. It has no nosecap, and nosecaps aren't available from CVA. I'm not sure but I think this is what is called a "Kentucky Pistol". In any case, I was thinking about cutting it down to a halfstock pistol, and welding in the two holes where the nosecap screws would have gone.

Anybody have an opinion to share about this? I think it would make this firearm unique. I don't care about historical accuracy on this particular one because I plan on shooting it as much as possible.

I'm not a huge fan of the wood on this one, but it is in pretty good shape overall. Rather than carefully strip the barrel, I haphazardly ran a scotch bright pad over the badly scratched bluing and came away with a unique effect of highlighting around the drum and muzzle. I think it gives the gun the permanent appearance of being dirty from having been fired, so I might simply leave it like this.

This image is a little out of focus, but this derringer is so small it's hard to fill a frame with it. This is a little 41 caliber smoothebore boxlock. It was unassembled when I got it in a very old box. I believe this to be the same as the kit you can buy from Dixie. It is made in Italy, I believe by Pietta.

I didn't like the grips on it originally, as I didn't do as good of a job fitting them, and I didn't care for the look of the wood so much. One night while polishing it with some Brasso, I accidentally smudged some black on the grips and actually liked the effect, so I blacked the gribs, sanded them lightly with some 220 grit paper, and applied 3 coats of Tung Oil for what now look like fairly handsome grips.

I also have some acrylic solid surface material I've thought about cutting into an alternate set of grips.

I have decided to leave the gun as rough as possible so as to give it a crude, maybe original appearance. The brass is scratched, the grips are blackened, and the hammer still has a lot of the casting marks in it, although it is heat treated. After a good polishing, the gun looks like it really might have been carried in the pocked of a gambler from the 1850s.

Here is a picture of them all together:

I am very pleased with my work overall. I'm still learning a lot about how to fit and assemble these kits, but I've gotten to learn a lot more since my first kit.

The flintlock is cool to shoot, and it represents what I originally wanted when I first posted on this site. In retrospect, I'm not sure if I would have continued shooting black powder had I first bought a flintlock. I am still having some difficulty getting it to reliably ignite at the range, although I am using PyrodexP in the flashpan. I plan on buying some 4F powder ASAP now that I have the gun working.

I shot all 3 guns today at the range. The derringer I shot with .395 roundball and 015 patch. it is frighteningly inaccurate as I expected, although from 10 paces I can usually hit a B34-RC target.

The flintlock shoots surprisingly well when it shoots. The bore is nearly perfect on this gun, and I suspect it must not have been fired very much.

The percussion lock shoots pretty well, but the bore had developed some rust. I brushed and brushed and cleaned, and eventually got most of the rust out, but there was some minor pitting in the bore. I worked the sear pin with a Carborundum rod to smooth out the trigger. First two shots of the day I nailed dead center on the same B34 RC target from 15 yards. The last 3 shots were a little less consistent, but probably still within an 8 inch circle or so.

Both of the larger pistols are .45 caliber. I shoot .440 roundball with a 010 patch. I have heard of some people patching with a 015, but I haven't tried that yet. I usually bring a scoop with me from my Lee scoop set when I shoot black powder, so today I made all of my shots with a 35 grain charge of PyrodexP powder. The derringer of course can NOT be fired with this charge, but rather instead I shot about a 9 grain charge of Pyrodex P.

And that's all I have to report! Feel free to criticize where you see problems, and offer advice, solicited or otherwise. Plenty of pictures here for everybody to see!