Hi,

I've worked over many India-made locks. They all had crude mainsprings that were much too strong but the spring may not be the only source of your heavy trigger pull. Look at your sear spring. The bend and lower leaf are almost completely compressed. Moreover, the full **** notch on the tumbler may not be oriented correctly such that the sear has to push the tumbler forward against the mainspring pressure in order to fire. Those are all common problems with these locks. I would certainly thin the

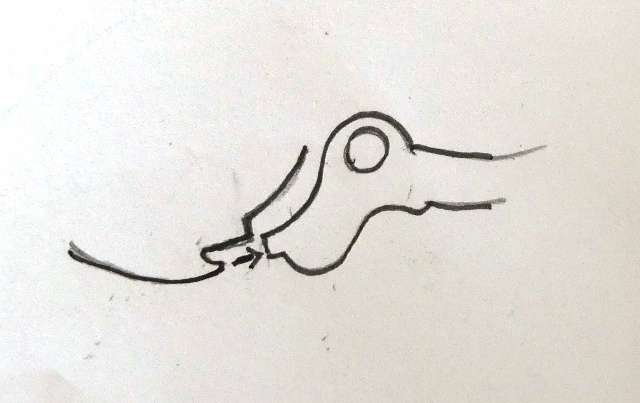

thickness of the lower leaf of the mainspring evenly tapering that thickness right from near the bend to the base of the hook. Then I would grind a bevel on the outside edge. Here is an example of a musket lock I made. Note the shape of the mainspring, which matches the original guns.

Note how open the bend is of the sear spring. Yours is totally closed except the end curves down to the sear. That spring has almost no where to go when the trigger is pulled so you likely will have to grind the end a little so it does not press on the sear so strongly. Assuming you are not familiar with hardening and tempering springs, I suggest grinding. Alternatively, if I was fixing your lock, I would heat the sear spring red hot, open up the bend with a screw driver, straighten the lower leaf, and then fit it in place. Then I would heat it bright orange red with a MAPP gas torch and quench in brine (salt mixed in tepid water)

not oil. Then I would polish it bright and heat with a small propane torch. Heat slowly and watch the colors change from yellow, to bronze, to purple, to deep blue, then keep heating until it becomes a light sky blue color. Stop heating and let air cool completely. After heat treating, install the spring and if too heavy, grind a bevel in the lower leaf to weaken it. Next up, the tumbler. Yours might be OK but often they are poorly made. The face of the full **** notch must be along a line draw straight down that face to the center of the tumbler spindle.

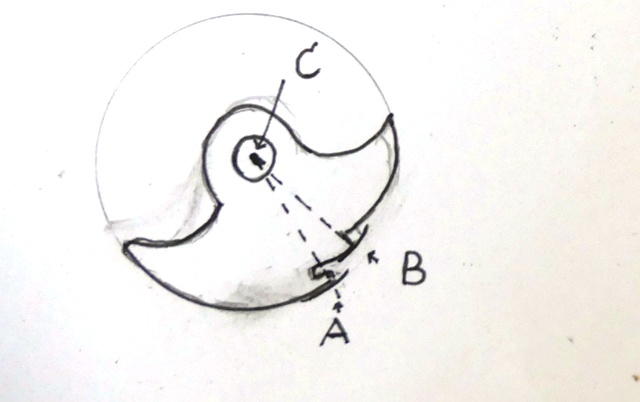

If it is angled too far upward, the sear has to push the tumbler forward to release. Simply stone or use a flat diamond file to orient the face correctly if out of line. Now the next problem you may face if you lighten the trigger. The sear may catch in the half **** notch when fired. I believe so many India made guns have excessive trigger pulls because that way the heavy force of your finger keeps the sear up and away from the half **** notch when fired. As you lighten the trigger, that no longer may be the case. The diagram below shows the problem.

Line A-C must be equal to or better, shorter than line B-C. If longer, the sear risks hitting the half **** notch when fired.

That is particularly true when lightening the trigger pull on these military locks with no fly detents in the tumbler. After lightening the trigger pull by grinding the mainspring and sear spring, you may have an issue with the half ****. The solution is to grind, or stone, or file the top of the lip down with a diamond file so line A-C is equal to or shorter than line B-C. Hopefully, you don't have need to reduce trigger pull that much to cause this problem but I've described how to fix it if you do. Finally, smooth and polish both the bottom of the sear bar where it hits the trigger and the top of the trigger bar. That will help a lot as well.

dave