Does anyone have info on the quality of barrel making in Europe in that era. What methods were used, any difference with 18th century work?

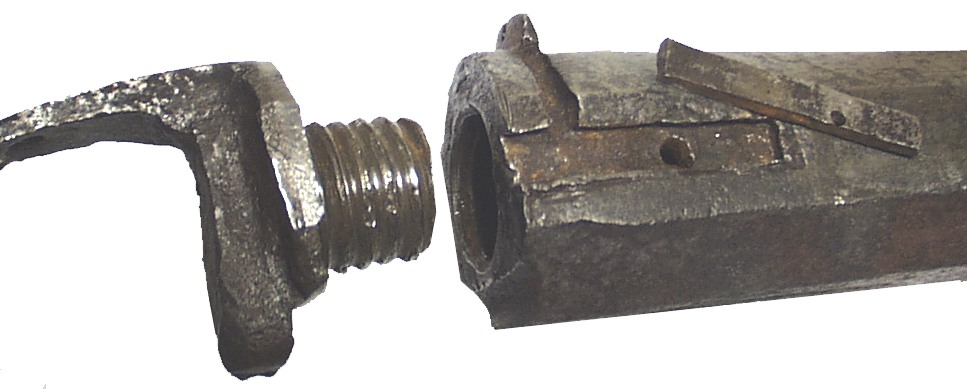

I know screw thread cutting was particulary difficult in general back then so I'm wondering about the how breechplugs were fitted :hmm: Did musketeers half expect their guns to blow up or were they reliable :thumbsup: I'm guessing relatively low quality powder and windage kept pressures down generally but I'm just curious...

I know screw thread cutting was particulary difficult in general back then so I'm wondering about the how breechplugs were fitted :hmm: Did musketeers half expect their guns to blow up or were they reliable :thumbsup: I'm guessing relatively low quality powder and windage kept pressures down generally but I'm just curious...