-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1816 Musket barrel work?

- Thread starter Cheyenne

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Guest

Well mmmmm I will say I don

1) Remove the nipple and place a bolt of the right size soldered permanently in the old nipple threads and smooth off.

Is that Silver Soldering you speak of???

Guest

Finding a new barrel will be more dificult than just running down to Wally-World. It's a pitty that Bannerman closed its doors. Gun Parts Corperation, out of West Hurley NY, might have a replacement. Dixie Gun Works?

It is not unusual to cut the breech section and add length to an origional in the restoration process. Many origional rifles were shortened at both breech and muzzle. You will also require a new lock if returning to flint, and what happened to the flash hole? Was it plugged, welded?

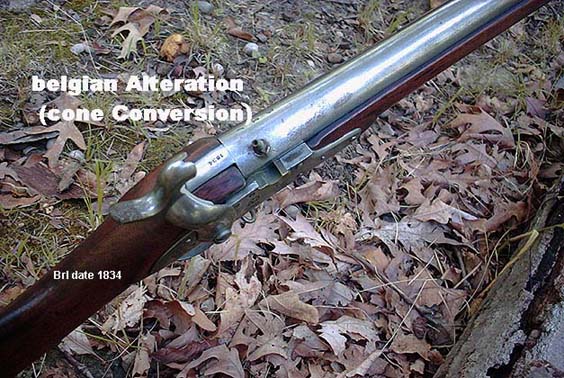

The musket you own is unique in it's present state, showing one of the more unusual methods of conversion to a new technology. It appears to be in almost mint condition, arsonal coversion. I would leave it exactly as it is and display it with pride as a transition weapon that started with a two hundred year old technology and finished its use through one of the simplist conversion methods ever devised.

Origional pieces are too rare to monkey around with at this stage in history. There are only a handful of people I would trust with this work, and even fewer I would trust with using a welding torch on an origional barrel. Please do not distroy the history you already hold in your hands.

Why not send a private e-mail to Dave Gardner, one of our new members who specializes in restoration work. Perhaps he can advise you or shed more light on this sbject.

:imo:

It is not unusual to cut the breech section and add length to an origional in the restoration process. Many origional rifles were shortened at both breech and muzzle. You will also require a new lock if returning to flint, and what happened to the flash hole? Was it plugged, welded?

The musket you own is unique in it's present state, showing one of the more unusual methods of conversion to a new technology. It appears to be in almost mint condition, arsonal coversion. I would leave it exactly as it is and display it with pride as a transition weapon that started with a two hundred year old technology and finished its use through one of the simplist conversion methods ever devised.

Origional pieces are too rare to monkey around with at this stage in history. There are only a handful of people I would trust with this work, and even fewer I would trust with using a welding torch on an origional barrel. Please do not distroy the history you already hold in your hands.

Why not send a private e-mail to Dave Gardner, one of our new members who specializes in restoration work. Perhaps he can advise you or shed more light on this sbject.

:imo:

B.Habermehl

45 Cal.

- Joined

- Jul 29, 2004

- Messages

- 766

- Reaction score

- 7

If the threads are in good shape any solder will do fine. The threads are what really take the load. The solder is really just glue or sealent in this case. Think of it as "Locktite-lead" :winking: I would use common plumbing solder for ease of use and relatively low temp. I would tin both parts bring them up to heat again then screw them together while hot reheat then add a little solder, to help guarentee joint fill out :m2c:

Guest

ya all the solder dose is hold the plug in .Is that Silver Soldering you speak of???

HOWEVER!!!!!!!!!!!!!!

as ghost states if this is an origenal peice DO NOT MONKEY WITH IT !!!!!!! I would leave it alone , if you want a flint version then look around for a replica .

im with Ghost 100% on this point , i didnt realize it was an origanl peice and only people with great exsperiance should ever convert or restore such things

Well, at least I got some input.....first, let me calrify....the one pictured is near mint and a full length musket....I would have no intentions of "monkeying" with it.

Many surplus conversion muskets were sold and shortened from the muzzle....they were like a cheap single shot shotgun in the 1800's.

What I have is one such cut down musket. 1816 percussion conversion, Harper's ferry lock that though patina, has no pitting. Barrel was shortened fromn the muzzle to 28".....should be a full 42" length. Stock was also cut back.

What I'd like to do is to restore it to original length, either I'll use a Dunlap forstock, or just restock it. Barrel bands (newly cast) are available, so hardware ismn't a problem. Only "problem area" is the barrel itself. I would like to bring this one up to speed, and save the primo for Living History and display.

What I need is either a new barrel, or have the original one "stretched"....hiding the weild under a band. getz can make a barrel, as can a bunch of others......that's really not a sticking point, what is, is the installation of the cone itself. It requires the area to be built up a bit, then drilled/tapped for the cone (nipple).

I should have been a bit more specific, I have no intention of "reconverting" either of them back to Flint, just want to bring the cut down one up as it'll never be a collector item, per sey, and would be a fun shooter.

Thaks for the numbers for Smith and Rayl, I'll try them. I've contacted several CW arms specialty "gunsmiths" known in the skirmish side of this with no luck.

Preferably, I'd like to use a new barrel as I'd like it to be a shooter with live as well as blank rounds, but it's the cone instalation where I need to find a 'smith to help out a bit.

Many surplus conversion muskets were sold and shortened from the muzzle....they were like a cheap single shot shotgun in the 1800's.

What I have is one such cut down musket. 1816 percussion conversion, Harper's ferry lock that though patina, has no pitting. Barrel was shortened fromn the muzzle to 28".....should be a full 42" length. Stock was also cut back.

What I'd like to do is to restore it to original length, either I'll use a Dunlap forstock, or just restock it. Barrel bands (newly cast) are available, so hardware ismn't a problem. Only "problem area" is the barrel itself. I would like to bring this one up to speed, and save the primo for Living History and display.

What I need is either a new barrel, or have the original one "stretched"....hiding the weild under a band. getz can make a barrel, as can a bunch of others......that's really not a sticking point, what is, is the installation of the cone itself. It requires the area to be built up a bit, then drilled/tapped for the cone (nipple).

I should have been a bit more specific, I have no intention of "reconverting" either of them back to Flint, just want to bring the cut down one up as it'll never be a collector item, per sey, and would be a fun shooter.

Thaks for the numbers for Smith and Rayl, I'll try them. I've contacted several CW arms specialty "gunsmiths" known in the skirmish side of this with no luck.

Preferably, I'd like to use a new barrel as I'd like it to be a shooter with live as well as blank rounds, but it's the cone instalation where I need to find a 'smith to help out a bit.

Guest

OHHHHH well now,,,,why didnt you say so LMAO no really i guess i totaly missunderstood you lol

oh and please dont take my capital letters as yelling , i was just trying to push home the point .

I am not to sure if there is many smiths who would do a belgiam conversion , its tricky , if you get things to hot the breach area will not hold under load . good luck I hope you find somebudy

oh and please dont take my capital letters as yelling , i was just trying to push home the point .

I am not to sure if there is many smiths who would do a belgiam conversion , its tricky , if you get things to hot the breach area will not hold under load . good luck I hope you find somebudy

I think what you need to do is take a visit to the Rifle Shoppe. Their catalog has all the parts that you would need. Your major problem will be making contact with them and getting the parts.

The Rifle Shoppe

Follow the catalog links to US Rifles and the 1816.

Think long and hard about your restoration work.

Mike

Private Grenadier

First of Foote

The Rifle Shoppe

Follow the catalog links to US Rifles and the 1816.

Think long and hard about your restoration work.

Mike

Private Grenadier

First of Foote

Cheyenne I have an 1816 that had a drum conversion and was cut back to 33" length. I ended up restocking it with a Dunlop stock and got the parts to convert it back to flint from the Rifle Shop. The barrel, What you are interested in,I sent to Bobby Hoyt. He streched it out to full length,relined it ,removed the drum and welded up the hole so it could be drilled for a touch hole. Excellent work! You couldn't even see a weld line and it shoots great. His adress is R.A.Hoyt,Freischutz Shop,700 Fairfield Station Rd.,Fairfield,Pa 17320. #717-642-6696.

One thing tough expect at least a 6month wait to get your barrel back because of his backlog and being in the process of moving into a new shop, but the wait is well worth it!

Bob

One thing tough expect at least a 6month wait to get your barrel back because of his backlog and being in the process of moving into a new shop, but the wait is well worth it!

Bob

Similar threads

- Replies

- 3

- Views

- 336

- Locked

- Replies

- 38

- Views

- 5K

- Replies

- 4

- Views

- 366