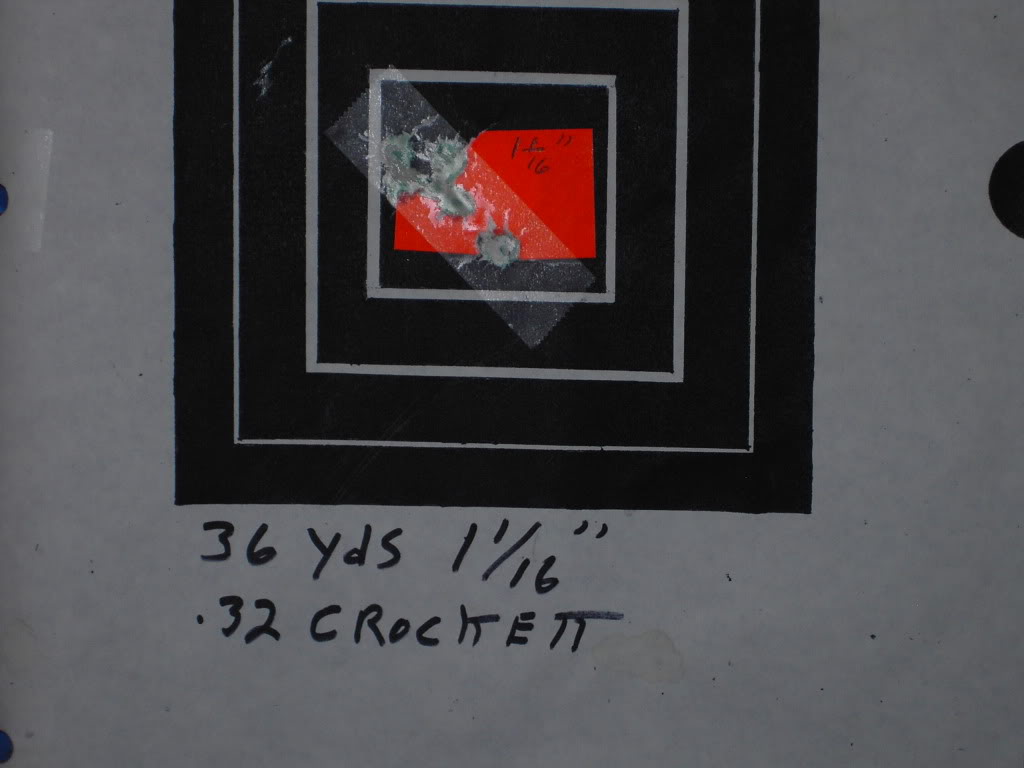

My experience is a little different, I typically use the Dutch Schutz method, after numerous trials, settled on 1:8 ballistol and water, shooting consistently under an inch.I agree with this.

I'll even poke the bear a little more . . . I think the least important factor in the load is patch lube. I've tried different patch lubes once I got the powder, ball, and patch thickness set . . and they didn't make much difference in accuracy in my .32, 50, or smoothbore. A lubed patch loads nicer . . and probably impacts fowling, but when I collect shot patches downrange they all look the same. . . I am not saying it doesn't make any difference, I just think it is the least of the factors. . . case in point, a lot of guys talk about their loads and many have the same powder volume, ball, and patch thickness, but far less common is the same lube. . . but I'm very open to hearing people disagree. . . and I say that even as a fan of Dutch Schultz's methods.

Experimented with numerous concentrations of Dawn, olive oil, tallow, etc... even tried several commercial products, and had trouble grouping even 2-3 inches with everything else the same.

The only thing I found that would shoot as well in my guns was the green Teflon coated patch material bought from Mr. Arrowwood, but don't have the ability to make that myself.

Last edited: