You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.40cal conical?

- Thread starter roundball

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Didn't someone on the forum experiment with cast pistol bullets in a 40?

Here is Rapine's offering in a bullet that might work. Looks kinda like the old 38-40 bullet, but like Bob308 said, might need a false muzzle to start 'em straight.

http://www.buffaloarms.com/browse.cfm/4,2187.html

Here is Rapine's offering in a bullet that might work. Looks kinda like the old 38-40 bullet, but like Bob308 said, might need a false muzzle to start 'em straight.

http://www.buffaloarms.com/browse.cfm/4,2187.html

Last edited by a moderator:

gmww

70 Cal.

- Joined

- Sep 4, 2004

- Messages

- 4,693

- Reaction score

- 4

Not knowing the actual size in .000 its hard to say. But, I would think the Lee pistol bullet moulds would be a cheap start. If I go the route of .40 cal. (I've been thinking about it too.) I'd probably use a piece of the barrel as a sizer.

I'll out to the garage and check the size on the Lee's I have.

Edit: My Lee is the .401, 175 grns, TC.

I'll out to the garage and check the size on the Lee's I have.

Edit: My Lee is the .401, 175 grns, TC.

- Joined

- Oct 2, 2006

- Messages

- 808

- Reaction score

- 18

You could take that .38/40 bullet & size it to a hair under BORE size, that way you won't need to use a starter. The bullet will bump up on firing. I'd recommend using a felt or card wad under the bullet. All the conicals I shoot in my muzzleloaders are bore size & accuracy is normally very good.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

My brother, and his friend, Phil Quaglino, are the .40 caliber shooters I know, and really KNOW the round well. So, I called him and sent your question to him. After talking to Phil, he noted that there are two main problems with shooting Conicals in a .40 caliber ML rifle:

1. The greenhill formula still applies, and if you have a 1:48 ROT in the barrel you bullet needs to be only 1.5 times the diameter of the bore, or about 6 tenths of an inch long to stabilize. That leaves you shooting pistol bullets, mainly those for the .38-40.

2. Groove depth. On ML rifles, the grooves are much deeper, so you can shoot a PRB. The grooves are at least twice as deep as what is normally put in a barrel designed to shoot bullets. That causes problems in keeping the gases from cutting and melting the bullet before it escapes the muzzle of your barrel!

Phil has a fast twist barrel with a 1:16 ROT. He is shooting a 305 grain round nose cast bullet, designed for the .40-65 rifle. The grooves are also shallower, designed for shooting cast bullets, rather than the PRB.

Phil also shoots PRB .40s, with the deeper grooves, and PRBs, but he doesn't try to shoot the conicals in them.

However, T/C was selling a " Mini Ball" in .40 caliber similar to one made and sold by Rush Creek Roundball.1-877-674-4949; or 1-877-674-4947. Phil sizes these bullets back down to .400 and loads them in his .401" bore. The sizing dies can be bought for about $20.00.

Rapine molds also offers .40 caliber pistol bullets, and rifle bullets, in varying weights and sizes. I have not checked with RCBS, but they may also have such bullet molds. Lee has a couple of molds for 40 caliber. Most of the pistol bullets are in the 175-185 grain weight, but they are short enough that they will stabilize in the 1:48 ROT barrels.

As for sealing gases, I recommend using an OP wad, and then even add a coarse filler, like Corn Meal on top of the OP wad to push the bullet down the barrel. The meal will fill any gaps in the deep grooves that the OP wad can't reach, but the OP wad is stronger and will do a better job of holding back most of the gas. The problem will always be that deep- usually square bottom-- groove depth. If the bullets are cast from soft lead, or pure lead( My brother bought some 20:1, Lead to tin alloy lead from John Walters of Walter's Fiber Wads, in Oklahoma, that turn out beautiful bullets for his .45-70 ) the bullet should be expected to " bump up", or "obturate" enough to take the spin of the rifling.

I think the key to successful accuracy with .40 caliber conicals is to be careful how long a bullet you choose for the ROT, sticking with that 1.5 times the bore diameter. These pistol bullets mentioned, the Rapine 40175, and 401180 are about .66" long, but should be stabilized with that fast twist rifling.

Then keep the velocities within reason. The better Ballistic's Coefficient and the elongated shape of any conical will drive that bullet much deeper than any PRB, so you don't have to worry about depth of penetration, even at modest velocities. With the bullet sized to your bore diameter, it should slide down the barrel easily, and then you only have to decide if you want to put an OS card down on the bullet to keep it in its position against the OP wad and fillers. On a target range, the OS card would not be necessary. Hunting, it might be a good idea.

If your muzzle is coned, you might actually want to try sizing the bullets .001" OVER bore diameter, so you have to score the bullets on the lands to drive them down the barrel. That would help keep them straight, and obviate any need for a false muzzle.

I have not checked the Cowboy Action ammunition suppliers, but the .38-40, as well as some of the newer .40, and .41 caliber pistol rounds have come back in favor, and there probably are sources of bullets for reloaders in those sports.

YOu might also call Eddie May and ask him what he has, or can cast for you. Peter tells me that he has talked to Tony Vance, the owner of Rush Creek Roundballs, and Tony told him he bought out the casting tools and molds from a man who retired, and he has dozens, if not hundreds, of molds he still has not examined or catalogued. So, talk to these guys directly about what you need. I bet they will be willing to cast up a reasonable order.

1. The greenhill formula still applies, and if you have a 1:48 ROT in the barrel you bullet needs to be only 1.5 times the diameter of the bore, or about 6 tenths of an inch long to stabilize. That leaves you shooting pistol bullets, mainly those for the .38-40.

2. Groove depth. On ML rifles, the grooves are much deeper, so you can shoot a PRB. The grooves are at least twice as deep as what is normally put in a barrel designed to shoot bullets. That causes problems in keeping the gases from cutting and melting the bullet before it escapes the muzzle of your barrel!

Phil has a fast twist barrel with a 1:16 ROT. He is shooting a 305 grain round nose cast bullet, designed for the .40-65 rifle. The grooves are also shallower, designed for shooting cast bullets, rather than the PRB.

Phil also shoots PRB .40s, with the deeper grooves, and PRBs, but he doesn't try to shoot the conicals in them.

However, T/C was selling a " Mini Ball" in .40 caliber similar to one made and sold by Rush Creek Roundball.1-877-674-4949; or 1-877-674-4947. Phil sizes these bullets back down to .400 and loads them in his .401" bore. The sizing dies can be bought for about $20.00.

Rapine molds also offers .40 caliber pistol bullets, and rifle bullets, in varying weights and sizes. I have not checked with RCBS, but they may also have such bullet molds. Lee has a couple of molds for 40 caliber. Most of the pistol bullets are in the 175-185 grain weight, but they are short enough that they will stabilize in the 1:48 ROT barrels.

As for sealing gases, I recommend using an OP wad, and then even add a coarse filler, like Corn Meal on top of the OP wad to push the bullet down the barrel. The meal will fill any gaps in the deep grooves that the OP wad can't reach, but the OP wad is stronger and will do a better job of holding back most of the gas. The problem will always be that deep- usually square bottom-- groove depth. If the bullets are cast from soft lead, or pure lead( My brother bought some 20:1, Lead to tin alloy lead from John Walters of Walter's Fiber Wads, in Oklahoma, that turn out beautiful bullets for his .45-70 ) the bullet should be expected to " bump up", or "obturate" enough to take the spin of the rifling.

I think the key to successful accuracy with .40 caliber conicals is to be careful how long a bullet you choose for the ROT, sticking with that 1.5 times the bore diameter. These pistol bullets mentioned, the Rapine 40175, and 401180 are about .66" long, but should be stabilized with that fast twist rifling.

Then keep the velocities within reason. The better Ballistic's Coefficient and the elongated shape of any conical will drive that bullet much deeper than any PRB, so you don't have to worry about depth of penetration, even at modest velocities. With the bullet sized to your bore diameter, it should slide down the barrel easily, and then you only have to decide if you want to put an OS card down on the bullet to keep it in its position against the OP wad and fillers. On a target range, the OS card would not be necessary. Hunting, it might be a good idea.

If your muzzle is coned, you might actually want to try sizing the bullets .001" OVER bore diameter, so you have to score the bullets on the lands to drive them down the barrel. That would help keep them straight, and obviate any need for a false muzzle.

I have not checked the Cowboy Action ammunition suppliers, but the .38-40, as well as some of the newer .40, and .41 caliber pistol rounds have come back in favor, and there probably are sources of bullets for reloaders in those sports.

YOu might also call Eddie May and ask him what he has, or can cast for you. Peter tells me that he has talked to Tony Vance, the owner of Rush Creek Roundballs, and Tony told him he bought out the casting tools and molds from a man who retired, and he has dozens, if not hundreds, of molds he still has not examined or catalogued. So, talk to these guys directly about what you need. I bet they will be willing to cast up a reasonable order.

- Joined

- Aug 21, 2004

- Messages

- 1,429

- Reaction score

- 2,292

I have a .380 hollowpoint conical designed for the Lyman .36 pistol. The cylinders on the Lyman are .380, not .375. I've tried this conical patched (10 thou's patch) in my flintlock rifle and it shot well. I think if I had a barrel with a faster twist, like a .40 barrel, maybe 1 in 48 twist or faster on a T/C hawken type gun, this conical would be absolutely deadly on deer sized game and smaller. I would be willing to send you some Roundball to try if you are so inclined. They would be better in a percussion gun imho ..... I send some a couple of years to a fellow in Florida and he said they are deadly on the small wild boar that run around his place.

Ohio Rusty >

Ohio Rusty >

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

J.D. said:Didn't someone on the forum experiment with cast pistol bullets in a 40?

I've shot a few .41 mag cast bullets in my .40. The guy who gave them to me to try had swaged them through a piece of cut-off GM barrel (1 in 48 twist). I only tried them out to 50 yds, but they shot good with 60 grs. of fffg. Took a deer with one that had been hollow pointed by a ball screw (I had very few so I pulled them instead of shooting them out when refreshing my loads), and it opened that buck up real good.

Hornady did sell these, I believe in hard lead, but I haven't seen any for a while. If I ccan find a mold I'd buy it and take a piece of barrel to make a swage out of. It pre-engraves the bullet lightly. The important thing to remember is if you do this with any bullet to make sure the rate of twist in the swage matches the barrel.

Thanks for the replies and experimental possibilities...I was really asking / hoping to specifically learn about one that was known to be commercially available for the .40cal...like for example T/C makes a Maxi in .32 and .36 cals...but it doesn't sound like one exists.

no sorry to say the .40 does not have a maxi or a real or any other bullet mold. just round ball.

as i said before i used .38-40 bullets. i was going to try a bullet for the .40-82 it is 285 gr. the old timers used them in the .38-40 pistols.

the correct twist for a .40 is 1-48.

as i said before i used .38-40 bullets. i was going to try a bullet for the .40-82 it is 285 gr. the old timers used them in the .38-40 pistols.

the correct twist for a .40 is 1-48.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

Bob: The correct twist for a RB in a .40 is your 1:48. If you are shooting conicals, you want something faster, and rifling that is no more than .003" deep. That 1:16 ROT barrel that Phil Quaglino just puts them into the same hole all day long. You have to have the faster ROT to stabilize those longer, heavier bullets.

Remember that a .40 caliber RB, depending on exact diameter, is going to weigh about 85-92 grains. When you are shooting a .38-40 pistol bullet, the weight will be 180-185- double the weight of that .40 cal. RB! It doesn't have to travel as fast as you would push a RB load to kill deer at reasonable ranges. The much better B/C, the longer bullet, and the heavier weight vastly improve the downrange performance of the .40 caliber bullet.

I am convinced that the only reason you see no .40 caliber bullets- REAl, or maxi-balls( miniballs) etc. from commercial suppliers is that no commercial maker of MLers is making and marketing a .40 caliber rifle. That is because in so many states the .44 caliber is the minimum caliber for use in hunting deer.

There are .40 caliber pistol bullets being made in volume, for the CAS trade, and casters making the .40 caliber rifle bullets, however. You find cast .40 and .41 caliber bullets being made for 10mm and .41 caliber revolver and pistol cartridges used in Speed and Action, combat shooting matches, too.

So, you don't have to buy a mold, if you don't cast. Tony Vance is certainly the man to call about any order of cast bullets. But, if I lived closer to Eddie May, I would not hesitate to find out what he has,too.

At most, you might have to invest in sizing dies to either squeeze down, or " bump up" the diameters of the cast bullets to fit your particular gun.

BTW, Phil's experiments on this issue were dictated by the fact he can't take much recoil anymore. He has a defibrillator, and a pace maker, and the recoil can set off the defibrillator, which will knock him to the ground! He wanted a light weight rifle in a small caliber that would kill deer out to no more than 50 yards, so he could use light loads, and keep the recoil down. Many years ago- in the 1930's when he was a kid- he killed deer shooting a .32 caliber cartridge in a rifle.

He is about to begin experimenting with a .38 caliber rifle to reduce the recoil further. :grin: :wink: :shocked2: :hatsoff:

Remember that a .40 caliber RB, depending on exact diameter, is going to weigh about 85-92 grains. When you are shooting a .38-40 pistol bullet, the weight will be 180-185- double the weight of that .40 cal. RB! It doesn't have to travel as fast as you would push a RB load to kill deer at reasonable ranges. The much better B/C, the longer bullet, and the heavier weight vastly improve the downrange performance of the .40 caliber bullet.

I am convinced that the only reason you see no .40 caliber bullets- REAl, or maxi-balls( miniballs) etc. from commercial suppliers is that no commercial maker of MLers is making and marketing a .40 caliber rifle. That is because in so many states the .44 caliber is the minimum caliber for use in hunting deer.

There are .40 caliber pistol bullets being made in volume, for the CAS trade, and casters making the .40 caliber rifle bullets, however. You find cast .40 and .41 caliber bullets being made for 10mm and .41 caliber revolver and pistol cartridges used in Speed and Action, combat shooting matches, too.

So, you don't have to buy a mold, if you don't cast. Tony Vance is certainly the man to call about any order of cast bullets. But, if I lived closer to Eddie May, I would not hesitate to find out what he has,too.

At most, you might have to invest in sizing dies to either squeeze down, or " bump up" the diameters of the cast bullets to fit your particular gun.

BTW, Phil's experiments on this issue were dictated by the fact he can't take much recoil anymore. He has a defibrillator, and a pace maker, and the recoil can set off the defibrillator, which will knock him to the ground! He wanted a light weight rifle in a small caliber that would kill deer out to no more than 50 yards, so he could use light loads, and keep the recoil down. Many years ago- in the 1930's when he was a kid- he killed deer shooting a .32 caliber cartridge in a rifle.

He is about to begin experimenting with a .38 caliber rifle to reduce the recoil further. :grin: :wink: :shocked2: :hatsoff:

I used to have a Lee 175gr mold for a .40 s&w that was called the "Tumble lube" design and it cast a .401 bullet using wheel weights. It wouldnt surprise me if pure soft lead and a coned barrel on the .40 wouldnt work!

Food for thought.

Food for thought.

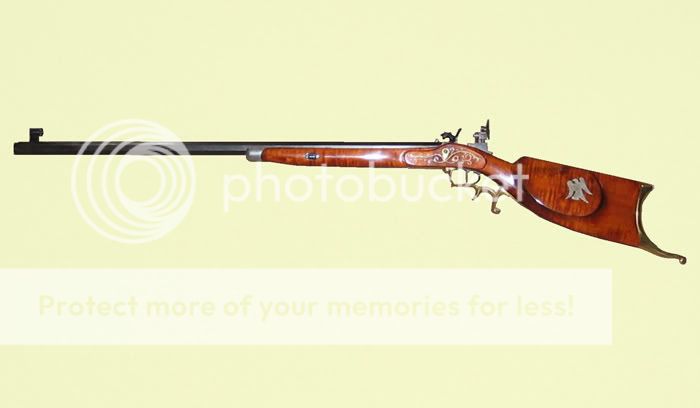

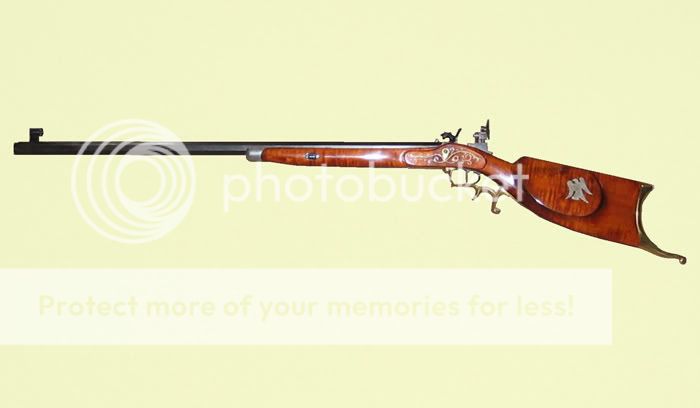

These are .3950 diameter Paper Patched bullets that I use in my .40 caliber Schuetzen.

They are available from

Montana Precision Swaging

P.O. Box 4746

Butte, Mt 59702

Phone/Fax 406-782-7502

The upper box shows the 300 grain bullets while the lower box shows the 400 grain bullets.

These were patched using .0010 thick "Dress Pattern" paper that "the one in control" allowed me to have.

Two wraps of this paper added to the .395 diameter of the solid lead slug gives the patched bullets a diameter of .3990 which is a very snug fit into my guns .4000 diameter bore.

I've lost the paperwork from Montana Precision Swaging so I can't varify this but I believe they also offer this bullet in a .390 diameter which would allow the use of slightly thicker paper for the patching.

It is not obvious but these bullets do not have grease grooves. The cylindrical part of their body is smooth, while as you can see, the rear is concave to allow the paper to be twisted into.

These bullets are not inexpensive. AIR several years ago they were going for about .25 cents each and with the increased price of lead these days I would expect the price now to be higher.

Notice that even the 300 grain bullet is quite long making a fast twist barrel important to getting the accuracy they are capable of.

As my Schuetzen has a Phil Quaglino 1:18 twist barrel on it there is no problem with stabilizing the .400 grain bullet but if they were used in a slower twist barrel I would think that the 300 grain bullet is about the heaviest one that would shoot well.

Also, because the diameter is rather small the breech pressures and gas wear of the nipple is high.

I suggest using 2Fg powder rather than 3Fg powder with these bullets and expect to replace the nipple after a few hundred shots.

I must admit that I get a few chuckles at the shooting range when I have the 400 grain bullets laying on the reloading bench.

Folks look at them and ask questions like, "How much powder do you have in that paper case?"

When I tell them that there isn't any powder, just pure lead their jaws drop and they just stare at them while saying things like, "Holy Sh*t"! :rotf:

Zonie: tell us more!It's legal in my home state to use a 40 caliber on deer so I've thought about a 40. The issue was how well a conical would work. I have thought why hasn't a longer conical ever been used and thought maybe it was impossible to get down a barrel- same thing with the paper patched bullet- I thought maybe the paper got all torn up.

I am going to voice my thoughts, some probably wrong so I'm really sort of asking a question.

On the 40 caliber.

1. Get a barrel to shoot the conical accurately- sounds like maybe a 1/18 twist- how about groove depth with paper patch? non- paper patch?

2. It is my impression you can shoot PRB out of a faster twist barrel if you slow down the ball. If a light charge was used could PRB's be accurate- even with a light charge it seems like they could be used for squirrel.

3. How difficult is it to load a paper patched conical with the lengths you mentioned? False muzzle, special tip on the ramrod? Etc.

I am going to voice my thoughts, some probably wrong so I'm really sort of asking a question.

On the 40 caliber.

1. Get a barrel to shoot the conical accurately- sounds like maybe a 1/18 twist- how about groove depth with paper patch? non- paper patch?

2. It is my impression you can shoot PRB out of a faster twist barrel if you slow down the ball. If a light charge was used could PRB's be accurate- even with a light charge it seems like they could be used for squirrel.

3. How difficult is it to load a paper patched conical with the lengths you mentioned? False muzzle, special tip on the ramrod? Etc.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

Zonie: Consider using the Berylium-copper nipples available from Treso, using Ampco metals. They are much harder than the stainless steel nipples, and resist heat erosion much better.

I agree that using FFg powder behind these heavy conicals makes more sense.

A 300 grain conical should be available and could be paper patched for this use. that would be more than adequate to kill any deer on this continent. :thumbsup:

I agree that using FFg powder behind these heavy conicals makes more sense.

A 300 grain conical should be available and could be paper patched for this use. that would be more than adequate to kill any deer on this continent. :thumbsup:

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

That's the beauty about those .41 pistol bullets I have used. They're a short conical and the 1 in 48 twist stabilizes them real good, at least at the shorter ranges. They weigh 172 grs. which pretty much doubles the weight of the .395 RB I normally use. We can use .38 cal. for deer in WV, but from the experiences I've had with the .40, I'm not too impressed with the killing power of the light RBs unless I get a head shot.

If you engrave the rifling into the bullet with the proper swage, you can shoot these in a deeply rifled barrel. Using soft lead will allow it to obdurate in the barrel and if one wishes, he can use a over powder wad to improve the seal.

As for the berylium/copper nipples, I've only had experience with one and it was on a Whitworth that I bought from another guy. I'm sure that the lack of maintainence played a part, but when I went to replace this nipple, I could only remove it with a pair of vise-grips after a good soaking of penetrating oil. And it was so hard it crumbled as I removed it. When I got it out, I saw that the threaded section had badly eroded from heat, actually was partly melted, and had allowed the gases to erode some of the threads and metal of the bolster. I ended up drilling it out, re-tapping it oversized and making a new sleeve to screw the new nipple into. This may have been an unusual situation where this type of nipple failed, but it was enough for me to just stick with steel and keep up with my maintainence better than the last guy who had it.

:thumbsup:

If you engrave the rifling into the bullet with the proper swage, you can shoot these in a deeply rifled barrel. Using soft lead will allow it to obdurate in the barrel and if one wishes, he can use a over powder wad to improve the seal.

As for the berylium/copper nipples, I've only had experience with one and it was on a Whitworth that I bought from another guy. I'm sure that the lack of maintainence played a part, but when I went to replace this nipple, I could only remove it with a pair of vise-grips after a good soaking of penetrating oil. And it was so hard it crumbled as I removed it. When I got it out, I saw that the threaded section had badly eroded from heat, actually was partly melted, and had allowed the gases to erode some of the threads and metal of the bolster. I ended up drilling it out, re-tapping it oversized and making a new sleeve to screw the new nipple into. This may have been an unusual situation where this type of nipple failed, but it was enough for me to just stick with steel and keep up with my maintainence better than the last guy who had it.

:thumbsup:

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

Very interesting information. I suspect that anti-seize "oil" should be put on the threads of all breechplugs, clean-out screws, and nipples with every cleaning or use.

I have been putting a drop of oil on my nipples after cleaning them after each shooting session. I also clean the threads in the bolster, and dry both before each gets a small drop of oil.

I have never had any trouble removing a nipple from one of my guns so long as I did this. I did have a problem many years ago with a percussion revovler when I put the nipples in "dry". I learned my lesson.

As hard as berylium copper is, I am not surprised that it might be brittle under such circumstances as you describe. I still think it is the least likely nipple to suffer enlargement of that small orifice inside the nipple, as the result of high chamber pressures. Perhaps the threads on that rifle were already Oversized for the nipple?

Since you acquired the rifle used, and can't know the condition of the threads before the Ampco/Treso nipple was installed, its hard to guess. If the gun was fired a long time without cleaning those threads, corrosion could have weakened the bolster's "steel" threads, and their may even have begun a electrolic action between the steel and copper, particularly if no oil was used.

I have been putting a drop of oil on my nipples after cleaning them after each shooting session. I also clean the threads in the bolster, and dry both before each gets a small drop of oil.

I have never had any trouble removing a nipple from one of my guns so long as I did this. I did have a problem many years ago with a percussion revovler when I put the nipples in "dry". I learned my lesson.

As hard as berylium copper is, I am not surprised that it might be brittle under such circumstances as you describe. I still think it is the least likely nipple to suffer enlargement of that small orifice inside the nipple, as the result of high chamber pressures. Perhaps the threads on that rifle were already Oversized for the nipple?

Since you acquired the rifle used, and can't know the condition of the threads before the Ampco/Treso nipple was installed, its hard to guess. If the gun was fired a long time without cleaning those threads, corrosion could have weakened the bolster's "steel" threads, and their may even have begun a electrolic action between the steel and copper, particularly if no oil was used.

crockett:

My Schuetzen is a specialized gun made for target shooting.

The rifling in this barrel is very shallow, about .002 deep which works fine with paper patched or multiple grease groove bullets but it doesn't work worth a dam for patched roundballs.

I have tried .395 balls with .010, .015 and .018 thick patches and fairly light powder loads and it still won't group at 50 yards. It likes heavy powder loads and patched roundballs even less.

I know the rifle is capable of grouping under 1 inch at 100 yards with the paper patched bullets so I attribute the poor results with a patched roundball to these shallow grooves.

As for loading, I grease the paper with a 50% beeswax/50% Vasoline combination right before I load the paper patched slug. It isn't real hard to get it down the bore but I do have to "wipe" the bore after each shot. I also found that if I pre-lube the paper more than a few minutes before loading it softens it to the point that it does tear.

As you can see, this gun is not the kind of thing one would want to carry around in the woods hunting a deer and it is the only fast twist muzzleloader I own.

If I had another fast twist muzzleloader I intended to hunt deer with I would look into the multi- grease-groved pure lead bullets rather than the paper patched ones or better yet, I would look for a nice .50 caliber slow twist gun.

My Schuetzen is a specialized gun made for target shooting.

The rifling in this barrel is very shallow, about .002 deep which works fine with paper patched or multiple grease groove bullets but it doesn't work worth a dam for patched roundballs.

I have tried .395 balls with .010, .015 and .018 thick patches and fairly light powder loads and it still won't group at 50 yards. It likes heavy powder loads and patched roundballs even less.

I know the rifle is capable of grouping under 1 inch at 100 yards with the paper patched bullets so I attribute the poor results with a patched roundball to these shallow grooves.

As for loading, I grease the paper with a 50% beeswax/50% Vasoline combination right before I load the paper patched slug. It isn't real hard to get it down the bore but I do have to "wipe" the bore after each shot. I also found that if I pre-lube the paper more than a few minutes before loading it softens it to the point that it does tear.

As you can see, this gun is not the kind of thing one would want to carry around in the woods hunting a deer and it is the only fast twist muzzleloader I own.

If I had another fast twist muzzleloader I intended to hunt deer with I would look into the multi- grease-groved pure lead bullets rather than the paper patched ones or better yet, I would look for a nice .50 caliber slow twist gun.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

Since you can't over stabilize a round ball, I would use as tight a patch/ball combination I can push down the barrel and go ahead and load up. The barrel is long enough to make sure that ball is spinning, so I would not be so concerned about the shallow rifling. I have just seen too many modern barrels that shoot RB pretty well, when you find the right powder charge. Use a chronograph if you have one, to let you know when those velocities start staying together for a given load. You are nearing a "sweet spot " with your powder charge, and should be able to locate the exact needed velocity to give you the smallest group fairly easily at that point.

My brother has been shooting 3 .40 caliber rifles, one .42, and one .45 in the past couple of years. With the .40 and the .42, he thought they would only handle a 45 grain charge. Well, now he's shooting a slightly different patch and ball combination, but he's using 50 grains of powder, in the .40s, and up to 65 in the .45.

Most of the barrels have the deep grooves and a 1:48 ROT, but one of them has a faster ROT, and shallow grooves. It still shoots RB well, with the right powder charge. He just fired 3 shot groups over his chronograph, and quickly found the right load, going up 5 grains at a time. Then he started testing up and down by 2 grain increments, and was surprised by reductions in the SDV. He doesn't think the shallow groove barrel shoots RB as accurately as his deep groove, slower ROT guns do, but he admits he's prejudiced. Most people would be very happy with the small groups he gets shooting RB out of the Fast Twist barrel.

My brother has been shooting 3 .40 caliber rifles, one .42, and one .45 in the past couple of years. With the .40 and the .42, he thought they would only handle a 45 grain charge. Well, now he's shooting a slightly different patch and ball combination, but he's using 50 grains of powder, in the .40s, and up to 65 in the .45.

Most of the barrels have the deep grooves and a 1:48 ROT, but one of them has a faster ROT, and shallow grooves. It still shoots RB well, with the right powder charge. He just fired 3 shot groups over his chronograph, and quickly found the right load, going up 5 grains at a time. Then he started testing up and down by 2 grain increments, and was surprised by reductions in the SDV. He doesn't think the shallow groove barrel shoots RB as accurately as his deep groove, slower ROT guns do, but he admits he's prejudiced. Most people would be very happy with the small groups he gets shooting RB out of the Fast Twist barrel.